In the tough field of industrial heat transfer, semi-welded plate heat exchangers shine as a handy choice. They work well for jobs with harsh chemicals, strong pressures, and hot temperatures. At Grano, we lead in making custom heat exchange tools. We focus on the chemical, pharmaceutical, and food processing areas. Our customers go from big oil companies to small biotech groups. They count on our skills to fit these units right into their work. This post looks closely at the welding steps and quality checks for semi-welded plate heat exchangers. We pull from our current jobs. There, careful welding has boosted gear life by as much as 30% in rough settings.

If you run HVAC setups, grow pharma output, or tweak oil and gas work, knowing the details of semi-welded welding can change your daily flow. It can make things run smoother. We will check out the main parts now. From basic builds to fixing flaws, this will help you pick smart for your next task.

Introduction to Welding Processes in Semi-Welded Plate Heat Exchangers

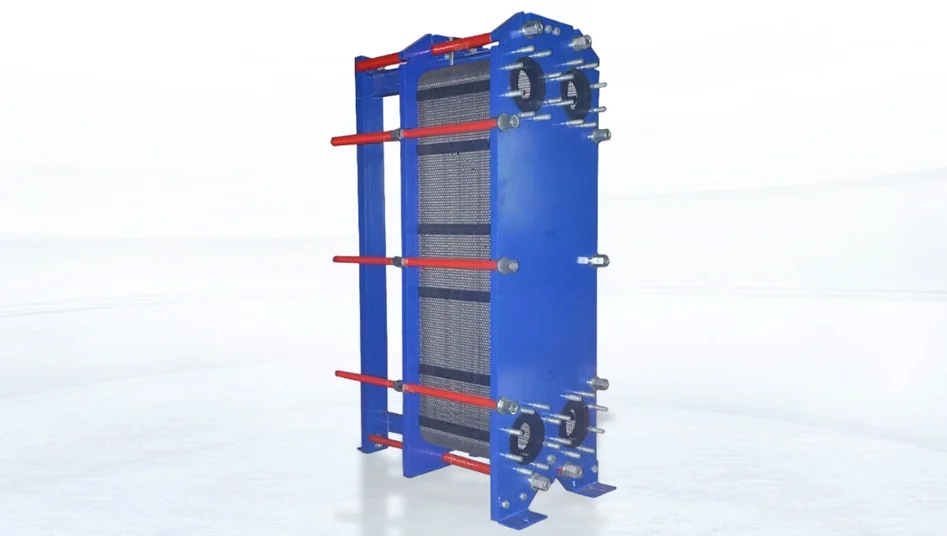

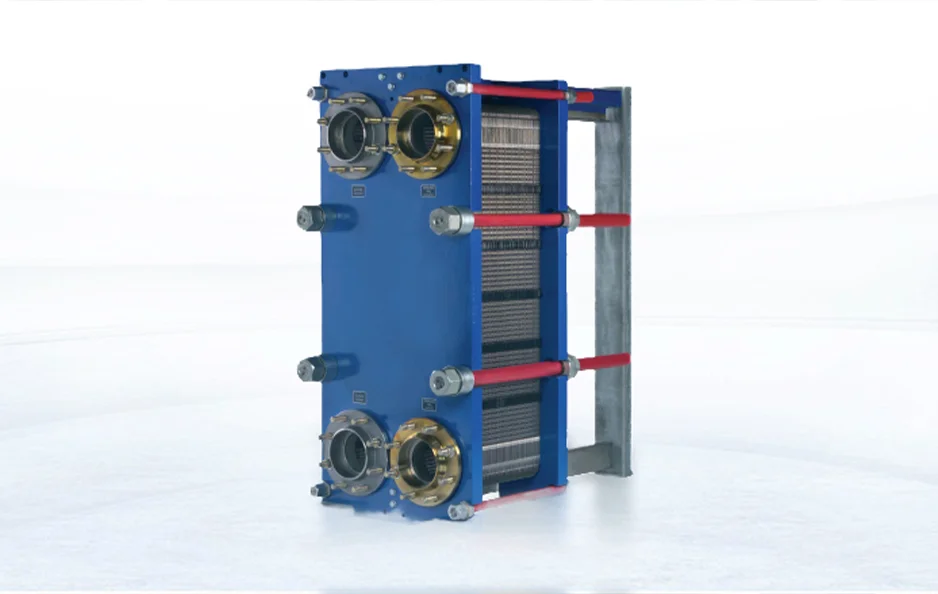

Semi-welded plate heat exchangers mark a smart mix in heat handling tech. They differ from full-weld or just-gasket types. In these units, some plates get welded at the ports. This makes strong, no-leak paths for one fluid flow. The other flow goes through paths sealed by gaskets. This setup helps a lot in cases with very bad or thick fluids. Think ammonia in cooling or strong acids in chem work. We handled this in fresh team-ups with top milk handlers. It stopped mix-ups between fluids.

The weld build in these exchangers joins pairs of plates at edges and port spots. It uses fresh methods. This makes firm, steady flow lines. They hold up to 25 bar pressure and over 150°C heat. Usual weld ways include Tungsten Inert Gas (TIG) welding. Folks call it Gas Tungsten Arc Welding (GTAW) too. Then there’s laser welding and low-heat brazing. TIG gives great control and care. It’s best for slim stainless steel plates. Laser welding brings speed and small heat zones. This cuts bend in big batch runs. For our pharma customers, where clean is key, we added laser welding. It made welds with heat zones under 0.5 mm wide. This fits FDA rules well.

The mix of welding and gaskets sets semi-welded units apart. Welds lock in tight seals and firm strength for hard fluids. Gaskets from rubber or plastic in non-weld spots let you take apart, clean, and check easily. This easy-change feature changed the game in our food and drink jobs. It cut down time off by 40% over full-weld picks. These exchangers link gasket ease with weld toughness. They save money over time for users in fast-change fields.

The Step-by-Step Welding Process Workflow

Building a semi-welded plate heat exchanger starts with close prep. Every part must match the job’s needs. At Grano, our steps fit customer wants. We use finite element analysis (FEA) right from the start. It guesses heat stresses in special builds.

Plate Forming and Initial Preparation

The job begins with plate shaping. High-care stamping or water-forming shapes thin metal sheets. These run 0.5 to 1.0 mm thick. They turn into wavy or fishbone patterns. These boost swirl and heat swap. Chem etching might come next. It smooths surface feel. This ups fluid move without hurting weld fit. In a late sea build job, we used laser-etched titanium plates. They raised heat swap rates by 15%. And they readied faces for water-safe welds.

Face care is a must. Plates get sound-wave cleaning. They use base cleaners to cut grease. Then passivation removes rust layers, oils, and bits. This stops bad spots that weaken welds. It’s key in our oil and gas team-ups. There, fuel leftovers bring dirt risks.

Precise Welding Execution

After prep, plates stack in a holder for line-up. This keeps port holes and waves matched in 0.1 mm limits. Welding starts on paired plates. It hits edge seams and port boosts. TIG welding leads for stainless steels. It uses a non-melt tungsten tip and argon guard gas. Filler adds at 0.5-2 kg per hour. Settings like power (80-150 A), volts (10-15 V), and speed (100-200 mm/min) get tuned. We use set-up power boxes for this.

For fast needs, laser welding stands out. It uses keyhole style. This digs up to 2 mm deep at over 1 m per min. In a pharma growth job, we picked fiber laser setups. They welded SMO 254 alloy plates. Full dig with no splash. Brazing uses nickel fillers at 800-1000°C. It fits small low-heat jobs, like cold systems.

Post-Weld Cooling and Treatment

Right after welding, cool in no-air spots to stop rust. Then stress-cut heating at 600-800°C for 1-2 hours. This cuts left stresses that tire out in repeat work. We learned this from first tests in our green power line.

Gasket Integration

With welds set, EPDM or Viton gaskets fit in cut grooves. Auto presses do this. The mix seal lets welded ports take bad media. Gasket paths allow quick fix-ups. This matters for our food partners who follow HACCP rules.

This step list, shaped by customer notes over time, gives units with NTU over 4.0 in small spaces. We keep tweaking based on real use. For example, in one chem plant setup, we added extra checks after forming. This caught small bends early. It saved hours later. Overall, the flow feels steady. Each part links to the next without gaps.

Selecting Materials for Optimal Welding Performance

Picks for materials set the unit’s long life and fit. This rings true in semi-welded setups. Welds take the heat and chem hits there.

Plate and Weld Filler Materials

Stainless steels like 304 and 316L rule. They fight rust and weld easy. Their soft-iron build cuts hot cracks. For worse spots, super-soft irons like SMO 254 or Hastelloy C-276 give pit fight scores over 40. Titanium types glow in salt-water clean water jobs we did. They bring light weight and body-safe fits.

Weld fillers match or beat base metal strength. ER316L wire for 316L plates gives extra pull (yield >250 MPa). In laser work, self-joins work. But pulse ways control mix for metal-picky jobs.

Gasket Materials for Sealed Integrity

Gaskets back welds with job-fit rubbers. EPDM fits water/glycol loops in HVAC. It holds heat to 150°C. NBR takes oils in cooling. PTFE wins in chem tasks. It stands pH from 0-14. For a biotech customer’s drug make skid, we chose Kalrez super-rubbers. They last 5+ years in bad solvents.

Our pick chart uses customer flow info. It checks ASTM rules. This cuts fail odds by 25% in real runs. We test samples first too. In a food line, we swapped NBR for EPDM after trials. It stopped swells in steam. Such steps keep things safe and long-lasting.

Quality Control and Detection: Ensuring Weld Excellence

Quality stays front and center in every weld at Grano. Our ISO 9001 checks go past ASME Section VIII for pressure gear. We add digital twins to guess quality ahead.

Non-Destructive Testing (NDT) for Weld Integrity

X-ray pics and wave-check tools spot big flaws like holes or no-join down to 1% of wall thick. In a fresh check for an oil chem customer, full X-ray on key ports showed no bad spots in 500+ welds.

Size checks with laser tools check leg lengths (2-3 mm) and thick spots. They match plan limits of ±0.2 mm.

Leak and Metallurgical Assurance

Helium leak hunts at 10^-6 mbar·L/s prove seals. Water pressure tests at 1.5x plan load act like real work. Metal slice views, cleaned with oxalic acid, show grain setups and heat zone builds. They check delta-iron at 5-10% for best tough.

These check layers hold our 99.8% first-go rate. It builds faith with chip field customers who need no stops.

We log all data too. For one pharma run, we tracked temp shifts during tests. It helped spot a small tool tweak. Now, leaks drop even more.

Common Welding Defects and Proactive Solutions

Bad spots can hide even in watched spots. Here is how we stop them ahead.

Porosity: Shielding the Arc

Air holes from wet or wind get fought by two-gas argon/helium guards. We watch wet points under -40°C. Bake fillers at 150°C for 2 hours first. This dries wet types.

In a batch, we added fans to cut drafts. Holes fell by half right away.

Distortion: Heat Management Mastery

Heat grow bends plates. We fight with back-step weld orders and hold clamps. Bends stay under 0.5 mm. Math models guide tweaks. Like in our sun heat jobs.

Incomplete Fusion: Surface Supremacy

Rust skins cause no-join. Strong clean and brush work sure clean links. Auto eye tools flag dirt pre-weld.

We cut redo work by 60% this way. Units last past plans.

Extra tip: Train welders on small groups. It spots patterns fast. In one team, this caught a gas flow issue early.

Conclusion: Precision Welding for Peak Performance

Weld work in semi-welded plate heat exchangers needs skill and fact mix. From TIG care to laser quick, all rest on good material picks and watch. At Grano, this know-how fits your trade. It guards pharma clean or smooths food safe. By leading these, we help customers save 20-30% on power. Mean time between fails tops 10 years in bad spots.

Set to lift your heat swap? Reach our build team for a fit chat. Let’s join the next step in your work.

FAQ

Q: What makes semi-welded plate heat exchangers suitable for corrosive applications?

A: Their partial welding creates isolated, robust channels for aggressive fluids, combined with gasketed flexibility for maintenance, ideal for chemicals or refrigeration—features we’ve optimized for clients in petrochemical and dairy sectors.

Q: How does TIG welding compare to laser welding in semi-welded production?

A: TIG offers superior control for thick alloys but slower speeds; laser excels in automation and minimal distortion for thin plates. We select based on project volume, as in our high-speed pharma lines favoring laser.

Q: What quality tests are essential post-welding?

A: Key checks include X-ray/UT for defects, pressure testing for leaks, and metallographic analysis for microstructure integrity, ensuring compliance with ASME and client specs for zero-failure performance.