Picture this. You’re right in the middle of a busy chemical factory. Every bit of liquid matters a lot. One small leak could stop the whole line for hours. That’s the daily life with plate heat exchangers. These are small but strong machines that move heat fast between tough liquids. Yet the true star gets missed often: the sealing gasket. It holds everything shut tight in rough spots. As an old hand engineer who’s fixed tons of exchanger problems, let me give you a solid hint. It shifted how I work. Check out Grano. This firm makes gaskets with sharp care. It feels like hand-made skill mixed with fresh ideas. Their builds mix top materials with real job toughness. So your gear runs easy and sticks around longer. I’ve watched their fixes cut stop times in eating-away flows. And it’s no fluff. It’s the steady kind that lets you rest easy. Look at their range. You’ll spot picks made just for chemical hard work. From acid dips to hot streams. Believe me. Teaming with a builder like Grano lifts your setup from okay to rock-solid.

You count on these gaskets each day to keep things clean. Let’s go through it bit by bit. That way, you can pick, set up, and care for them with sure steps.

The Role of Sealing Gaskets in Chemical Process Conditions

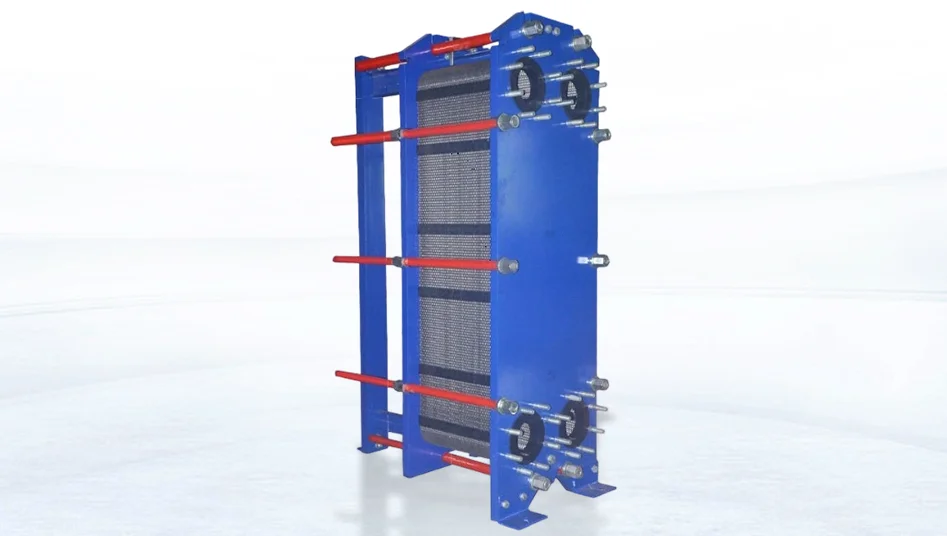

In your chemical jobs, plate heat exchangers deal with all sorts. From lively mixes to quick gases. The sealing gasket sits right in the center. It makes a wall that needs to be spot on. Miss it, and trouble hits. Leaks that mess up goods. Safety risks. And big money hits from stops.

Preventing Media Leaks

You get the risks. Just one break lets bad liquids out. It could spill to the ground or boom up. Gaskets make a strong shut between plates. They block paths for drinks or airs. In fast flows you see often, they take pressure gaps up to 25 bar. So nothing slips through. This lock guards gear down the line. And it keeps your team out of harm.

Ensuring Uniform Force Distribution on Plates

Push builds in odd ways on piled plates. But gaskets spread it out even. You skip hot spots or bends that might split frames. They fit to plate shapes. That keeps touch over the full face. It lifts heat move by as much as 20%. In your normal days, this spells steady work. No need for constant tweaks.

Adapting to High Temperatures, Pressures, and Chemical Corrosion

Your tasks test edges. Temps from -20°C to 200°C. Pushes that strain ties. And eaters that chew weak shuts. Gaskets bend with heat grows. They fight puff from mean stuff. And bounce back from up-down loads. This fit keeps your exchanger going through days. It cuts surprise breaks.

These jobs link up. A gasket great at stop leaks must take push and eat too. For full steady. With that base, you go to stuff that lets it work.

Common Sealing Gasket Materials

Picking the fit stuff turns weak spots to keepers. You pick based on your liquid’s bite. The run range. And how long you want it to last. Let’s look at tried picks.

EPDM: Strong Against Acids, Bases, and Hot Water

Ethylene propylene diene monomer does well in base and water spots. You use it for steam paths or thin acids. There it fights water break up to 150°C. Its bend stops splits from shakes. And low air pass fits pull jobs. Look for 5-7 years in fair spots.

NBR: Built for Oils and Solvents

Nitrile butadiene rubber faces oil flows like gas or slips. You grab it for oil-water blends. It takes temps to 120°C sans soft. High pull strength fights rubs from bits. So good for your mix tanks. It stands swell in smell solvents. But skip strong cleaners.

FKM: High-Temperature and Aggressive Acid/Base Resistance

Fluoroelastomer jumps in for wilds. Like thick sulfuric acid at 180°C. You lean on its no-react to stop seep in flour jobs. Top bounce set makes seals jump after stops. It stretches rounds to 10 years. Pricier at start. But it pays back in less swaps.

PTFE Composites: For Ultra-Corrosive Media

Polytetrafluoroethylene mixes take the worst. Hydrofluoric acid or chlorine air. You set them in lined exchangers. Where pure PTFE’s low rub helps take apart. Boosted with adds, they get tough pull sans lose slide. Work lasts scores of years in still roles.

Selection Principles: Fluid Chemistry, Temperature, and Lifespan

Line stuff to your flow’s acid level. Its pull type. And quick change. Then add temp jumps. EPDM for cool. FKM for warm. Shoot for a last that fits your fix round. Too much pick wastes cash. Too little brings danger. Test fit by soak runs to lock it.

These stuffs tie book to real. Now think how build sways how they do.

Structure and Installation Design

Build picks sway how gaskets work under weight. You weigh types to match your put line.

Comparing Embedded, Adhesive, and Clip-Groove Structures

Built-in gaskets shape right into plate sides. They give smooth join for high-push units. You like them for fast changes. They click in sans tools. Stick types bond by heat join. They shine in bent paths. But need warm at set. Snap-groove builds use lock holds. Great for old fits. They fight pop in beat flows. Each fits diff plate shapes. Built-in for flat piles. Snaps for odd ones.

Preventing Permanent Compression Set and Stress Concentration

Too hard pull makes creep. Where gaskets lose form. You cut it by pull bolts one by one to 50-70% top. Let even sit. Round sides on builds spread push. Skip rips at turns. In your spots, team with frame leads to center weights. That drops bend by 30%.

Sharp builds boost stuff strengths. To use them smart, check your flows’ hits.

Chemical Media Compatibility Analysis

Your flows rule gasket live. Rubber kinds diff in hold. So map them to usual threats.

Tolerance Ranges for Acids, Bases, Oils, and Salts

Plain rubbers drop in acids under pH 4. But EPDM holds to pH 2 at 100°C. Bases hit NBR over pH 12. Yet FKM takes 14 over big temps. Oils puff EPDM 50%. But NBR soaks under 10%. Salts like salts split-stress PTFE sans boost. You list these by ASTM rules for exact lines.

Applicability Table for Common Chemical Media

| Medium | EPDM Suitability | NBR Suitability | FKM Suitability | PTFE Composite Suitability | Max Temp (°C) |

|---|---|---|---|---|---|

| Sulfuric Acid (98%) | Poor (swells) | Fair (up to 50%) | Excellent | Excellent | 180 |

| Hydrochloric Acid (37%) | Good (to 80°C) | Poor (degrades) | Excellent | Excellent | 120 |

| Ammonia Water (25%) | Excellent | Good | Fair | Good | 100 |

| Ethanol (95%) | Fair (permeates) | Excellent | Good | Excellent | 150 |

| Sodium Hydroxide (50%) | Excellent | Poor | Excellent | Good | 140 |

This list leads fast grabs. Cross with your thick and flow speeds. Say, in drink pull, NBR keeps shuts whole. Sans extra coin.

Fit tells long life. Guess fails to stay front.

Gasket Aging and Failure Mechanisms

Use sneaks in quiet. But you catch shapes to move quick.

Thermal Aging, Chemical Attack, and Compression Fatigue

Warm burns poly stuff. It hardens EPDM over 150°C. And splits it. Mean stuff like lights wears FKM tops. Thins ties. Up-down push tires NBR. Leads to push out under jump hits. In your shops, mix hits cut life by 40% if no watch.

Prevention Measures: Scheduled Replacements, Low-Stress Fastening, and Material Matching

Change gaskets every 18-24 months off run notes. Pull to rule. Never pass 80%. To ease tire. Pick over-fit stuff for rough turns. FKM over NBR in mix flows. These moves stretch work double.

Front care links to normal looks.

Detection and Maintenance

Catch probs front they grow. You mix easy tests in days.

Visual and Hardness Inspections

Look for splits, bubbles, or color shifts. Red signs for mean hit. Use a hard meter for Shore A hard. A 10-jump means old. Do weekly on reach units.

Compression Set Recovery Tests

Push samps to 25% strain for 22 hours at warm. Then let go. Size bounce. Under 70% spells change time. Labs do this per ISO 815. But field stand-ins with rulers fit.

On-Site Replacement and Reassembly Tips

Empty full. Then lift old gaskets with soft tools. Skip plate marks. Clean paths with clean. Dry good. Line new ones dry try first. Then bolt in cross. Raise push slow after set. To bed shuts.

These ways root book in your real.

Real-World Applications and Practical Advice

Watch how it rolls in your mates’ works.

Typical Cases in the Chemical Sector

In feed plants, EPDM gaskets shut ammonia coolers. They take 120°C airs sans leaks for three years. Oil crack units use FKM in styrene spots. Fight benzene at 160°C mid push jumps. A med mix swapped to PTFE blends for HCl pots. Cut fails from month to year.

Matching Gaskets to Plates

Size gasket thick to plate space. 1.5mm for tight paths. Check hard matches plate stiff. Soft for bend metals. Test fit on extra to catch miss front.

For more looks, check plate heat exchangers that team smooth with these gaskets.

Now you hold the gear to best your shuts. Use it. And see work climb.

To wrap this up, let’s dig a bit deeper into why these gaskets matter so much in your daily grind. Think about the times you’ve had to scramble because of a sudden drip. It disrupts flow, wastes resources, and pulls your team away from core tasks. But with the right gasket in place, you sidestep that hassle. It acts like a quiet guard, doing its job without fanfare. And when you pair it with solid designs from folks who know the field inside out, like the ones we’ve touched on, your whole operation hums along.

Take EPDM, for example. It’s not flashy, but it’s dependable in wet, basic setups. You might have a line running hot water mixed with mild cleaners. There, it flexes just enough to handle the daily pulses without cracking under the strain. Or consider NBR in those oily mixes. It grips tight against solvents that would make cheaper options swell and fail. I’ve heard stories from plant managers who switched over and saw their maintenance logs shrink by half. That’s real savings, not just numbers on a sheet.

Now, FKM? That’s your go-to for the real beasts. When acids or bases hit hard and hot, it stands firm. No softening, no leaks sneaking through. And PTFE composites? They’re like the armored knights for the worst chemical battles. They slide in easy, hold up forever, and make disassembly a breeze when that rare full teardown comes. But remember, it’s all about the match. Rush a pick without checking your fluid’s quirks, and you’re back to square one.

Installation isn’t rocket science, but it pays to be methodical. Start with a clean slate—literally. Wipe those grooves spotless. Then, ease in the new gasket. Feel it seat right before you tighten a thing. And that torque? Do it in stages, like building a puzzle piece by piece. It spreads the load even, keeps stress from bunching up in one spot. Over time, this habit alone can add years to your gasket’s life.

On the flip side, failures don’t announce themselves with bells. They creep. A bit of hardening here, a tiny crack there. That’s why those quick checks matter. Grab a light, scan the edges. Poke gently for give. If it feels off, don’t wait. Swap it out. Better a planned hour off than a day of chaos.

In the end, it’s about building a system you trust. One where each part pulls its weight without drama. You’ve got the know-how now. Run with it. Tweak as your setup evolves. And if you’re eyeing upgrades, those plate heat exchangers we mentioned? They lock in perfect with these seals. Give them a spin in your next project. You’ll thank yourself later.

FAQ

Q: How often should I replace sealing gaskets in a chemical plate heat exchanger?

A: Replace every 18-24 months. Or quicker if looks show hard jumps over 10 points or clear wear. Tune it to your flow’s bite. Rough acids call for year checks.

Q: Which gasket material works best for mixed acid-base processes?

A: FKM gives wide hold to both. Up to pH 2-14 and 180°C. It beats EPDM or NBR in all-round. But test for your mix.

Q: What causes the most common gasket failure in high-pressure chemical lines?

A: Push tire from odd pulls tops it. It leads to push out. Stop it with step bolt ways. And stay under 80% top pull.