Selecting the right Plate Heat Exchanger for your condenser system is super important. It changes how well your system runs and how much money you spend. These devices move heat quickly, but picking the best one needs careful thinking. You have to consider heat needs, materials, care, and setup. This guide shares the key ideas to help you choose a Plate Heat Exchanger that keeps your system working great.

Checking the Heat Load and System Needs

To find the perfect Plate Heat Exchanger, start by looking at the heat load and system details. First, figure out the heat duty. This means working out how much heat the exchanger needs to move. Next, check the beginning and final temperatures of both liquids. Also, measure how fast the liquids flow. These facts help you size and arrange the Plate Heat Exchanger correctly. They make sure it can handle big loads safely and well.

Matching Heat Moving Power with System Conditions

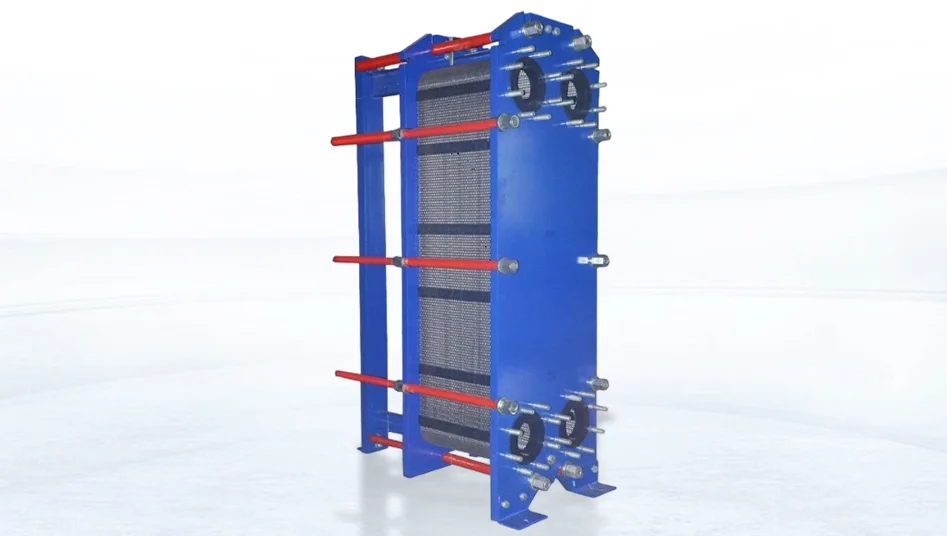

The Plate Heat Exchanger must match your system’s needs. It has lots of thin, wiggly plates that make paths for liquids. This design gives strong heat moving power, even with different temperatures and pressures. For example, Grano’s standard plate models work at up to 25MPa pressure and 200°C temperature. Their brazed models can take up to 40MPa and 300°C. These are awesome for tough cooling jobs in factories.

According to ASHRAE research, properly sized plate heat exchangers can achieve heat transfer coefficients of 3,000-7,000 W/m²°C, significantly higher than shell-and-tube exchangers (typically 300-1,500 W/m²°C). This explains why plate models require 50-80% less surface area for equivalent heat duty.

(Source: ASHRAE Handbook—HVAC Systems and Equipment, Chapter 47 | ashrae.org)

Thinking About Temperature Gap and Pressure Limits

A smaller temperature gap makes things more efficient. But it needs more plate space. Also, you have to balance pressure drop with liquid mixing to keep pumping costs down. Plate Heat Exchangers have some downsides. Their long sealing edges can leak. They only work below 150°C. The pressure difference is small, and they can’t handle huge amounts. If plates get dirty, you need to take them apart to clean. Knowing these issues helps you pick a model that works great without trouble.

How Does Plate Design Change Performance?

How Chevron Shape Affects Liquid Flow

The chevron (or herringbone) pattern changes how liquids move in the paths. Plates are shaped with waves or grooves. This makes them tougher and stirs the liquid, improving heat movement. Sharp angles make more mixing, which helps heat transfer but raises pressure drop. Softer angles cut resistance but give okay heat performance.

Flow Options: Single Pass vs. Multi-Pass Setup

Single-pass designs are simple and easy to clean. But they might not give enough time for heat transfer in big systems. Multi-pass setups send liquid through several zones in one unit. This boosts heat exchange. It offers flexible choices for complex condenser systems.

Balancing Mixing for Efficiency and Dirt Control

Lots of mixing improves heat transfer. But it can cause wear or dirt buildup sometimes. Plates are placed upside down, making many contact spots. These spots are spread evenly, so liquid flows around them, creating strong mixing. This leads to a high heat transfer rate. Choosing the right chevron shape balances efficiency with long-term strength.

Why Is Material Choice Key in Factory Uses?

Matching Materials with Liquids and Tough Conditions

Picking the right material decides how long the equipment lasts, especially in rough places like chemical plants or salty water systems. Common materials include stainless steel, copper, aluminum, aluminum alloy, titanium, and nickel. Choosing the right material stops rust damage or contamination risks.

Stainless Steel, Titanium, or Hastelloy: Which Works Best?

Stainless steel is cheap and fights rust well for regular use. Titanium is great for salty or chloride-heavy places because it strongly resists rust. Hastelloy is good for very harsh chemical liquids but costs more. Picking the right material for your liquid ensures good performance over time.

Long-Term Strength vs. First Cost

Materials like titanium cost more at the start. But they need less care and last longer in tough spots. This saves money over time. You should compare the starting price with the long-term benefits for your system.

How Do Care and Access Affect System Costs?

Why Easy Disassembly and Cleaning Matter

Detachable plate designs make care easier. They use little space and are simple to take apart and put back together. Regular cleaning fixes efficiency lost to dirt or scaling. This is key for systems with hard water or liquids with bits in them.

Gasket Type and When to Replace Them

Gaskets keep seals tight even with temperature changes. The gasket’s top and bottom must be smooth, with no bubbles or rough bits. Choosing strong gasket materials that fit your system’s temperatures stretches the time between replacements. This cuts down on leak risks.

Planning for Downtime: How Modular Design Helps

Modular plates let you remove or add parts without stopping the whole system. This lowers downtime during care or upgrades. The flexible design makes it easy to grow as needed.

When Should You Pick a Semi-Welded or Fully Welded Plate Heat Exchanger?

Checking Risks of Liquid Mixing

Semi-welded designs weld one side (often for refrigerants) and use gaskets on the other (usually for water). This reduces the chance of liquids mixing in sensitive systems, like those using ammonia for cooling.

Handling High Pressure or Rough Liquid Conditions

Fully welded models have no gaskets. They are perfect for risky liquids under high pressure where leaks could be bad. Brazed Plate Heat Exchangers use welding to join metal plates into a small unit. They are used a lot in chemical, oil, and natural gas industries for high-temperature and high-pressure settings.

Benefits for Ammonia, Hydrocarbons, or Risky Liquids

Systems using ammonia or hydrocarbons benefit from welded designs. These give strong containment, which is vital in dangerous industries like petrochemicals.

Can Plate Heat Exchangers Handle Changing Load Conditions Well?

Adjusting to Different Flow Rates Without Losing Performance

Factory systems often face changing loads because of shifting temperatures or production needs. The mixing-friendly design of Plate Heat Exchangers keeps performance steady even when loads change.

Why Fast Heat Response Matters in Active Systems

Quick response times are important in systems with fast load changes, like HVAC in big buildings. Plate Heat Exchangers are reliable and need less care.

Using Modularity to Meet Future Needs

Modular units let you add plates instead of replacing the whole exchanger. This makes it simple to grow as needs increase.

Where Can You Find a Trustworthy Supplier for These Needs?

Grano has a great history of helping many industries. For example, in 2021, an HVAC company in Mexico teamed up with Grano. They bought several Brazed Plate Heat Exchangers for air conditioning and hot water systems in Mexico City buildings. Also, in 2019, a client in India got detachable Plate Heat Exchangers for industrial cooling in parks. These units worked well and got high praise. Grano offers standard and custom solutions for industries like power, food processing, metallurgy, and petrochemicals.

How Do You Keep Your Condenser System Running Well Over Time?

Watching Dirt Buildup in Tough Places

Regular checks help spot scaling early. This stops performance drops, especially in systems with hard water or thick liquids that cause buildup.

Using Smart Care Plans

Sensors and data tools help predict when care is needed. This avoids breakdowns and keeps energy efficiency high while cutting downtime.

Setting Cleaning Schedules Based on Liquid Type

Cleaning should match how your liquids cause dirt buildup. This avoids extra work and keeps the system running at its best.

FAQs

Q: What’s the biggest benefit of using a Plate Heat Exchanger in a condenser system?

A: The main benefit is its awesome efficiency in moving heat. The wavy plates create mixing, which boosts heat exchange. This makes Plate Heat Exchangers small and great for cooling systems, saving space and energy.

Q: How often should I clean my Plate Heat Exchanger to keep it working well?

A: Cleaning depends on the liquids used. For hard water or liquids with bits, check for scaling often and clean when needed. A schedule based on liquid type, usually every 6–12 months, keeps efficiency high without extra work.

Q: Can a Plate Heat Exchanger handle harsh liquids like seawater?

A: Yes, but the material is key. Titanium is awesome for seawater because it fights rust well. Stainless steel works for less harsh liquids, while Hastelloy is great for very aggressive chemicals. Pick the right material to avoid damage.