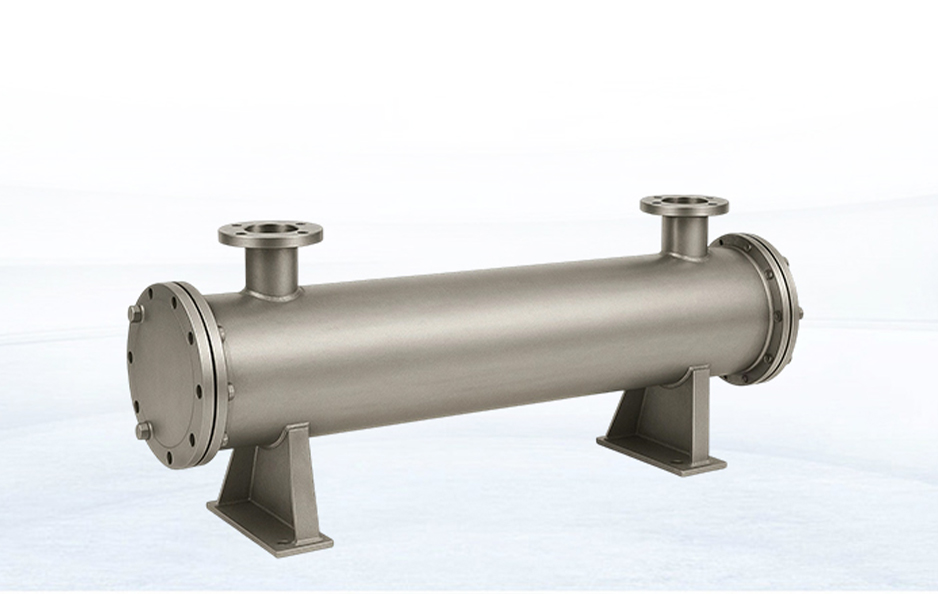

Shell and Tube Heat Exchangers: The Industry Workhorse for Efficient Heat Transfer

At the core of countless industrial processes lies the essential need to transfer heat from one fluid to another. For this critical task, the shell and tube heat exchanger remains the most trusted and versatile solution across the globe.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a class of heat transfer equipment built with a large outer shell (vessel) filled with a bundle of tubes. One fluid flows through the tubes (the tube side), while a second fluid flows over the tubes within the shell (the shell side). Heat is transferred from the hotter fluid to the cooler fluid through the walls of the tubes, without the two fluids ever mixing.

This robust and efficient design is engineered for reliability, durability, and high performance in even the most demanding applications.

Key Advantages of Our Shell and Tube Heat Exchangers

Proven Reliability & Durability: Their simple yet robust construction makes them exceptionally strong, capable of withstanding high pressures and temperatures that other exchanger types cannot.

Superior Efficiency: Our exchangers are meticulously designed with optimized baffle arrangements and tube layouts to maximize turbulence and heat transfer rates, ensuring optimal thermal performance.

Unmatched Versatility: They can handle a wide range of fluids, including water, oil, steam, chemicals, and gases. They are also easily customizable to meet specific pressure, temperature, and material compatibility requirements.

Ease of Maintenance & Service: The modular tube bundle design allows for easy access for cleaning, inspection, and repair, minimizing downtime and reducing long-term operating costs.

Scalable Design: From small-scale operations to massive industrial plants, the shell and tube design can be efficiently scaled to meet virtually any capacity requirement.

Common Applications

Shell and tube heat exchangers are the backbone of numerous industries, including:

Power Generation: Condensing steam in turbines and cooling lubrication oil.

Oil & Gas Refining: Heating crude oil and cooling process streams.

Chemical Processing: Precise temperature control for reactors and distillation columns.

HVAC & Refrigeration: Acting as condensers and evaporators in large chillers.

Marine & Naval: Cooling engine jacket water and lubricating oil.

Pharmaceutical & Food & Beverage: Sanitary heating and cooling of process fluids.

Why Choose Our Exchangers?

We don't just manufacture heat exchangers; we engineer thermal solutions. Each unit is custom-designed using advanced modeling software and built with high-quality materials to ensure peak efficiency, longevity, and a perfect fit for your specific process needs. Our commitment to excellence guarantees a product you can depend on for years to come.

Ready to optimize your heat transfer process? Contact our engineering team today to discuss your application and discover the perfect shell and tube solution for your operation.