Mechanical cleaning keeps Shell and Tube Heat Exchangers running smoothly by scraping off gunk like scale or algae that messes with heat flow and jacks up energy bills. Stuff like rotary brushes or high-pressure water jets gets the job done safely, and Grano’s smart designs with pull-out tubes and tough materials make upkeep a breeze. Regular cleaning saves money, cuts downtime, and keeps things humming in heavy-duty setups like refineries or HVAC systems.

The Importance of Maintaining Heat Exchanger Efficiency

Why Fouling Messes Up Shell and Tube Heat Exchangers

Fouling is a real pain for Shell and Tube Heat Exchangers. Stuff like scale, sludge, or algae piles up inside the tubes over time. This blocks heat from moving properly and makes fluid flow tougher. It leads to uneven temperatures and weaker performance. If you don’t deal with it, fouling can overheat parts or stress important pieces.

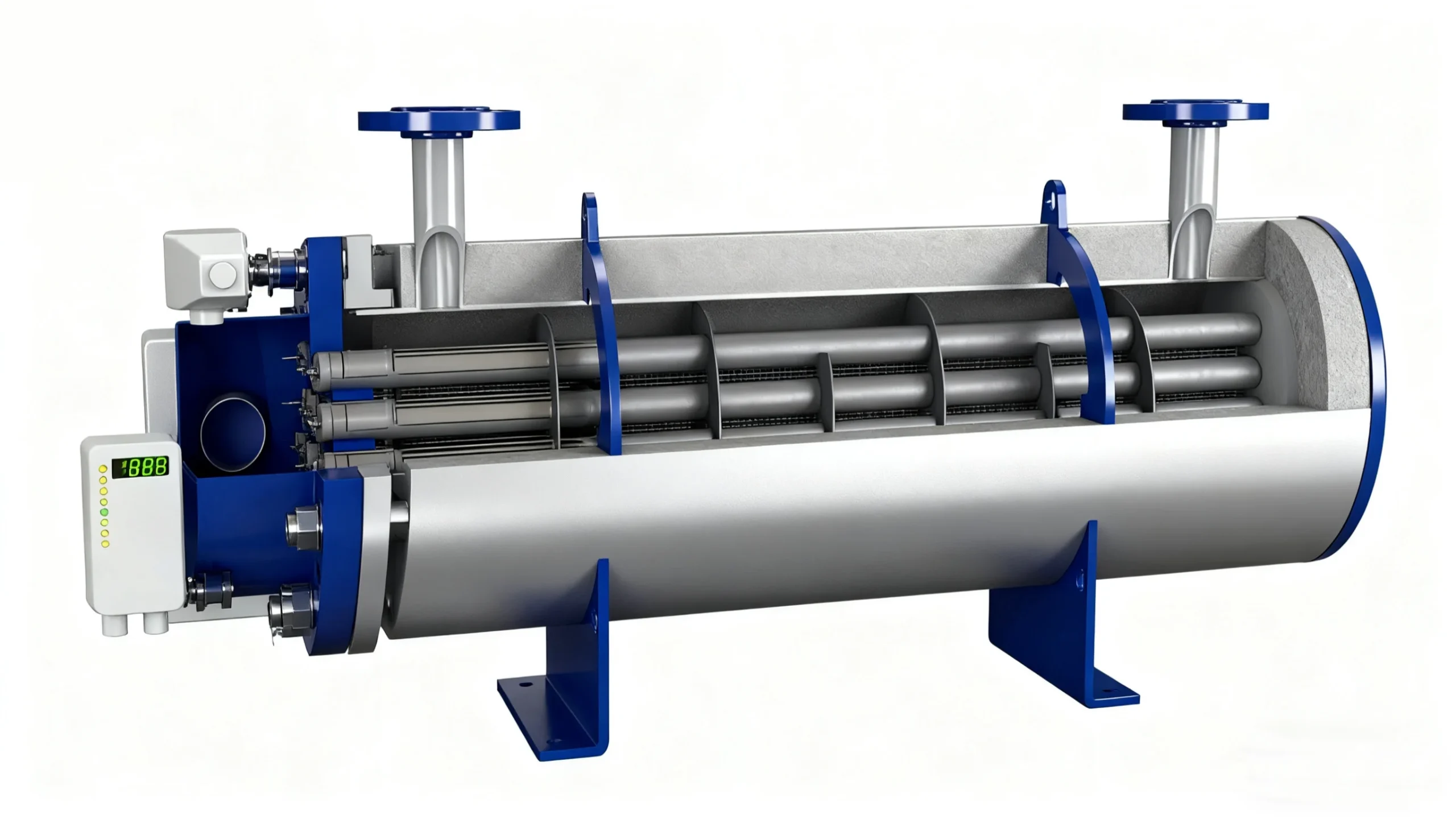

The Shell and Tube Heat Exchanger is a go-to for many industries. It has a bundle of tubes inside a shell. This setup is sturdy for big jobs but gets dirty fast because the tubes have so much surface area.

How Fouling Boosts Energy Costs

When fouling slows heat transfer, your system has to push harder to reach the right temperatures. Pumps work longer, or you need extra heating or cooling. This eats up more energy. The costs stack up quick—bigger bills, slower production, and more shutdowns for fixes.

Even a thin 1 mm layer of scale can cut heat transfer by up to 10%. That makes your system burn more energy, hitting your budget hard.

Why Regular Cleaning Keeps Things Running Smooth

Cleaning your Shell and Tube Heat Exchanger regularly stops fouling from causing trouble. Don’t wait for bad performance or high energy bills to show up. Planned cleanings clear out gunk before it hurts your system.

Grano builds Shell and Tube Heat Exchangers for tough industries like petrochemicals and steel. These handle big flows with low pressure drops. Regular cleaning keeps them working great, saving you from costly downtime.

Mechanical Cleaning Methods for Shell and Tube Heat Exchangers

What Is Mechanical Cleaning?

Mechanical cleaning uses tools to scrape fouling off tube insides. Think brushes, high-pressure water jets, or rotary tools made for tube shapes. Unlike chemical cleaning, it doesn’t use reactions. You get quick results with less waste to handle.

Mechanical vs. Chemical Cleaning

Chemical cleaning can work but might rust your exchanger if the chemicals don’t match the materials. It also needs careful handling because of toxic or reactive stuff. Mechanical cleaning is safer for workers and better for places where chemicals are a no-go. Plus, it lets you target just the dirty spots without shutting down everything.

Why Mechanical Cleaning Is Great for Industry

For big setups like refineries or power plants, mechanical cleaning has cool perks:

-

It’s fast to do.

-

It’s easier on the environment.

-

It works with automated tools.

-

It doesn’t wear out your gear over time.

These make it a top pick for units like the Shell and Tube Heat Exchanger built for high-pressure jobs up to 50 MPa.

Key Mechanical Cleaning Techniques for Shell and Tube Heat Exchangers

Rotary Tube Cleaning Systems

Rotary systems use spinning brushes or scrapers on flexible shafts. They’re awesome for blasting away hard scale that water jets can’t touch. These work great in the big tubes of heavy-duty Shell and Tube Heat Exchangers. Their simple design makes it easy to use rotary tools, either on-site or with built-in automation.

High-Pressure Water Jetting

High-pressure water jetting shoots water at over 20,000 psi to clear out debris. It’s perfect for soft stuff like algae or mud but can also crack hard mineral buildup if done right. Safety is super important—workers need protective gear, and the area has to be sealed off. The equipment should handle pressures higher than normal limits. Jetting works best during planned shutdowns when you can get full access without stopping production.

Pneumatic or Motorized Tube Brushing

Pneumatic brushes use compressed air to push spinning brushes through tubes. Motorized ones use electric power. These are popular in places like petrochemical plants or power stations where you need to clean lots of tubes fast. They’re great for medium fouling and can use soft or rough bristles depending on the mess.

How Grano’s Design Makes Cleaning Easier

Cleaning works better when your equipment is built for it. Grano’s Shell and Tube Heat Exchangers are designed to make maintenance simple.

Features That Make Maintenance Easy

These exchangers have tube bundles you can pull out. This lets you check or clean inside without taking everything apart. Clever baffle designs spread fluid evenly, cutting down on spots where gunk builds up fast. Grano picks materials like stainless steel, carbon steel, or copper to fight corrosion. These hold up in tough conditions, like temperatures up to 400°C, and keep scaling low.

Working with Automated Cleaning Systems

Some Grano exchangers work with automated cleaning tools, like rotary heads or pneumatic brushes, that attach outside. You can clean while keeping other systems running. This cuts downtime and keeps your output steady.

If you want gear that stays reliable with less hassle, Grano’s Shell and Tube Heat Exchanger is built for easy upkeep in tough industrial settings.

Benefits of Regular Mechanical Cleaning for Grano Heat Exchangers

Keeping Heat Transfer Strong

Regular cleaning stops gunk from acting like insulation inside tubes. This keeps heat moving as it should, saving energy by avoiding temperature losses. Your exchanger stays efficient even after years of use.

Longer Equipment Life

Cleaning often reduces stress from overheating or pressure spikes caused by clogs. This helps parts like seals, gaskets, and welds last longer. Grano offers heat exchanger accessories, like plates, gaskets, and bolts, so you can swap out worn bits fast during cleanings.

Less Downtime and Lower Costs

Planned cleanings let you work around production schedules, not scramble after a breakdown. This smart approach cuts emergency repair costs and boosts reliability, like improving how long your system runs between failures.

Grano’s Full-Service Solutions for Heat Exchanger Maintenance

For critical systems where uptime is everything, teaming up with a company that gets both design and field service is key. Grano offers:

-

On-site cleaning with top-notch tools.

-

Maintenance schedules that fit your production.

-

Expert advice from years in HVAC, petrochemicals, and steel industries.

Grano’s products are tested hard for structure, heat transfer, materials, and sealing. They stay solid even in harsh conditions. Whether you’re running a refinery or a chiller system, Grano delivers lasting performance.

FAQ

Q: How often should I clean my Shell and Tube Heat Exchanger?

A: It depends on your setup, but every 6 months to a year is common. If fouling is heavy, you might need quick brushings or jetting every 3 months.

Q: Can mechanical cleaning hurt my exchanger’s parts?

A: Not if you use the right tools, like soft brushes. These are safe for materials like stainless steel used in most industrial exchangers.

Q: What makes Grano’s Shell and Tube Heat Exchangers easier to maintain?

A: Removable tube bundles, smart baffle layouts, and tough materials like stainless steel or copper make cleaning and inspections easier without tearing everything apart.