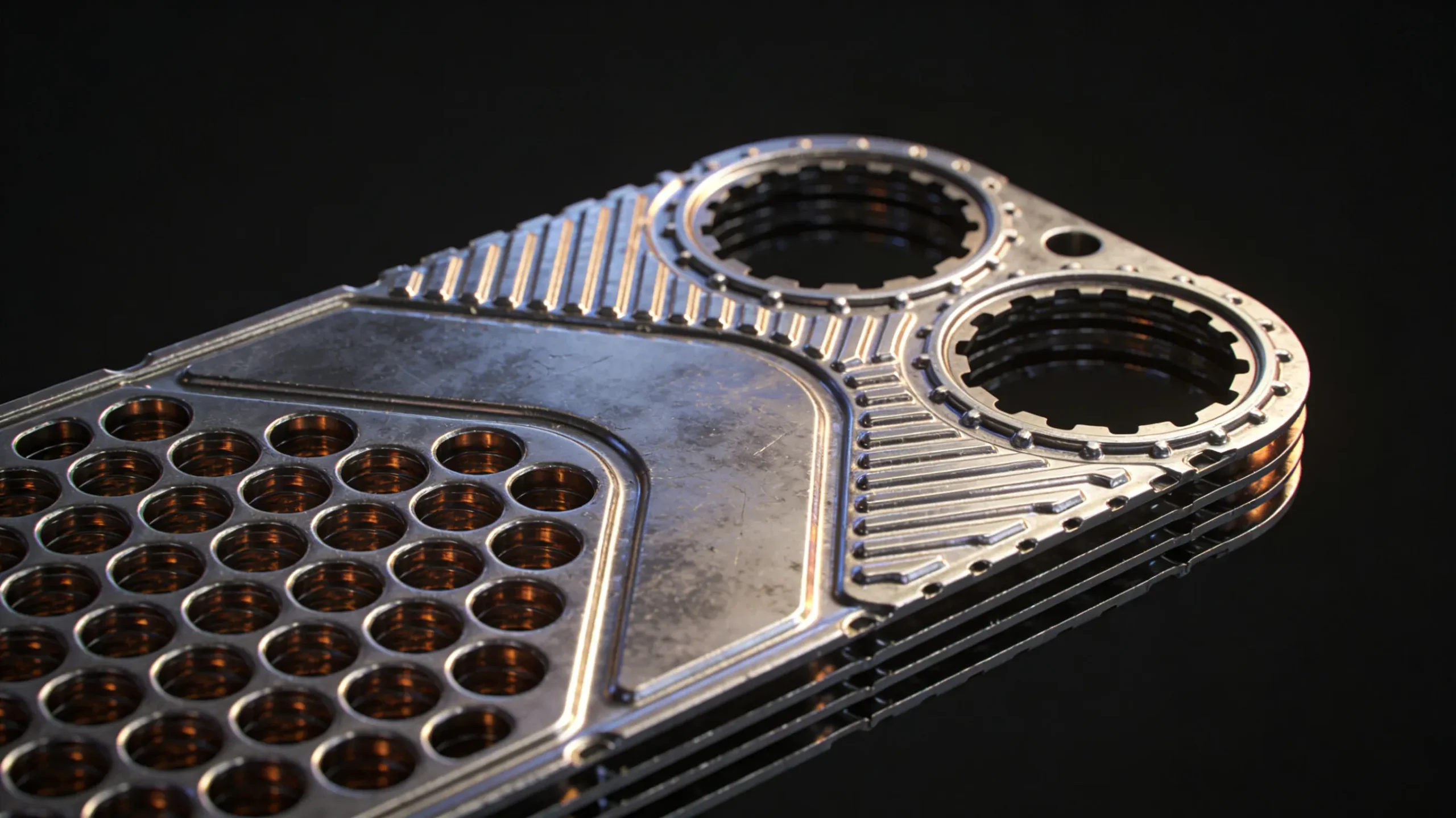

In the tough field of industrial heat control, nothing beats the annoyance of an unexpected machine breakdown. You put money into a solid setup, but only three months later, you spot a mixing problem between fluids or a quick fall in pressure levels. When you check closely, those stainless steel plates that seem bright and fresh at first glance show a scary truth under bright light, as they turn out full of small, pin-like holes.

People often brush off this issue as just poor chance or a bad set of metal sheets, but it seldom happens by pure accident. At Grano, our teams have looked over thousands of examples of Plate Heat Exchanger failure. We found that early holes in the plates usually come from a mix of wrong choices in materials, the problem with plate thickness, and certain mistakes during setup. And when these issues line up, even the priciest gear can break down way too soon.

This full guide will uncover the details of these odd leaks and give you a standard plan from the industry to make sure your gear holds up for years instead of mere months. Once you grasp the main reasons behind plate perforation, you can switch from fixing things after they go wrong to a forward-thinking approach that keeps your business costs in check.

The Invisible Drill Chloride Ion Pitting Corrosion

The top reason for holes forming in plates during factory use is a tiny process called pitting corrosion. Your plates might appear clean and smooth, yet they face damage at the tiniest level from one of the usual parts in factory water setups, which is chloride.

The Mechanism of Point Blasting According to industry standards, Chloride ions work like small drills. Stainless steel counts on a super thin and tight coating of chromium oxide, called the passivation film, to stay safe from rust. But chloride ions stand out because they can break through this coating. After the coating gets pierced, the metal underneath turns into an anode, while the nearby unbroken coating acts as a cathode. This setup forms a small but strong electrochemical cell that digs straight down into the metal. As a result, it makes a pit, yet the area around it stays fine, so the plate can seem perfect even though it has lost all strength inside.

The Temperature Catalyst Many workers think that if their water stays fairly cool or draws from a regular city source, they avoid rust problems. But this idea can lead to real trouble. When the liquid heat goes above 60 degrees Celsius, the action of chloride ions jumps up a lot. At those higher heats, even normal amounts of salt or hard minerals can speed up how fast the damage spreads. This buildup often causes a quick Plate Heat Exchanger failure in a setup that ran fine for years at cooler levels. In fact, the heat makes the chloride particles move quicker and hit harder against the protective layer, turning a slow wear into a fast attack that catches operators off guard.

Grano Strategy for Prevention Never try to guess what is in your water. Before you pick a machine or do Plate Heat Exchanger maintenance, you need a complete check of the water. If the check finds chloride above 150 ppm, then regular SS316L cannot hold up well anymore. In spots with lots of salt or chloride, Grano suggests moving to Titanium plates. Titanium builds a stronger oxide shield that resists chloride pitting almost completely at normal working heats, which wipes out the chemical risk in a reliable way.

The 0.1mm Thickness Trap Why Nominal vs Actual Matters

In today’s busy world market, lots of sellers cut prices by skimping on the costliest piece of the machine, which is the metal plates. This choice often brings the need for constant Plate Heat Exchanger maintenance because of plates that are too thin or not up to standard.

The Reality of Stamping and Pressing A plate sold as 0.5mm thick usually starts with raw material at just 0.4mm. Yet the issue runs deeper than a small number difference. In the making stage, workers press the plate into wavy shapes to build the swirl needed for good heat flow. This pressing pulls the metal quite a bit. So a 0.4mm plate ends up with weak spots as thin as 0.32mm after the press. Those spots turn into the main weak links where holes form under light pressure.

The Loss of the Sacrificial Layer In factory liquids, tiny bits like sand grains, rust bits, or salt crystals show up almost every time. When the flow runs fast, these bits rub like rough paper against the plate sides in what experts call erosion-corrosion. Plates with more thickness offer an added shield, working as a layer that takes the damage first. It takes much more time for rubbing or slow chemical eating to break through a thicker wall. But thin plates leave no room for mistakes. As soon as the pressed-thin areas face even light rubbing, they give way right away, which sparks a major Plate Heat Exchanger failure and costly stops in work.

The Grano Recommendation We push for the 0.6mm Standard in tough factory jobs. Sure, the starting price sits a bit above cheap options, but the working time often lasts two or three times longer. And when you add up the bills for new parts plus time lost from breakdowns, picking thicker plates saves money over the full run.

Physical Impact and Foreign Object Damage

At times, the reason for plate holes stems not from chemicals or build flaws but from straight-up physical hits. These breakdowns tend to happen right at the riskiest moments for gear, like the first run-up or after big Plate Heat Exchanger maintenance.

The Danger of Weld Slag and Pipe Debris As noted in industry safety standards, the time just after a fresh setup or pipe fix counts as the highest risk period. If you skip a good clean flush, bits of weld slag, metal scraps, or small rocks can slip into the tight paths of the plate heat exchanger. With strong flow pushing them, these pieces hit like sharp bits. They might punch right through the slim metal plates or jam in the wavy parts, which builds hot areas and wild swirls that speed up rust damage.

The Water Hammer Effect Shutting a hand valve fast or kicking on a strong pump all at once sends a pressure rush called a water hammer. Since plates stay slim on purpose to boost heat passing, they cannot handle these quick pressure jumps well. A bad water hammer might bend or split the plates at touch spots, which are the bumps where plates meet. This kind of wear from force leads to instant leaks between sides and full Plate Heat Exchanger failure.

Ensuring System Longevity To keep your gear safe, Grano points to three key steps. Start with putting a 60-mesh filter before the unit. This step stands as a must to block physical junk from reaching the plates. Next, use valves that close slow or auto systems to stop pressure waves. Last, make your Plate Heat Exchanger maintenance plan cover a full look at the filters so they do not block up and cause uneven pressure.

Conclusion Prevention is Cheaper than Repair

A heat exchanger that leaks without clear reason almost always points to a breakdown you could predict from poor planning or upkeep. By learning the exact triggers of plate perforation, you shift from fixes done in a rush to a smart ongoing plan that keeps your plant running at top shape.

At Grano, we hold that top build quality serves as the strongest safeguard. By choosing the right materials like Titanium for areas with high chloride, sticking to real 0.6mm thickness for lasting strength, and adding guards through filters and pressure checks, you avoid the headache of a machine leaking after just three months. We bring the know-how and the parts to make your heat systems a steady help, not a daily worry.

FAQ

Q If my plates are already leaking, can they be patched or welded to save money?

A Generally, the answer is no. Heat exchanger plates are extremely thin, usually between 0.5mm and 0.6mm. Welding creates heat-affected zones that are even more susceptible to future corrosion and warping. The standard professional approach for Plate Heat Exchanger maintenance is to identify the damaged plates and replace them with new ones. This ensures the integrity of the seal and the original heat transfer efficiency of the unit.

Q How can I tell if my perforation is caused by chloride or by physical debris?

A You should look at the pattern of the damage. Chloride pitting usually looks like tiny, dark pinholes that are often surrounded by a small amount of reddish or white mineral crust. Physical damage, on the other hand, often appears as scratches, gouges, or jagged tears. Physical damage is usually concentrated near the inlet ports where the fluid velocity is at its highest, whereas chemical corrosion can appear anywhere on the plate surface.

Q Why does Grano recommend 0.6mm plates when many competitors offer 0.5mm? A The 0.1mm difference might seem small, but it represents a 20 percent increase in wall thickness. In harsh industrial environments, that 20 percent acts as a critical safety margin against erosion and micro-corrosion. Our goal is to minimize Plate Heat Exchanger failure for our clients, and our data shows that 0.6mm is the ideal balance between high thermal efficiency and long-term structural durability.