Introduction: The Sound of Imminent Failure

In the busy, high-pressure area of factory heat transfer, people often check efficiency, temperature handling, and pressure loss. But they miss one key point. This point can cause big, sudden stops. It is the quiet mechanical danger called Fluid-Induced Vibration (FIV). If your shell-and-tube heat exchanger makes a steady low buzz, or even a repeating bang or clatter, that noise is not normal. It means your tube bundle is getting damaged bit by bit from the inside. FIV makes the thin tubes, which are the main part of your heat exchanger, shake hard inside the shell. This stress always leads to two bad results. One is tube contact with baffle holes that causes major wear. The other is quick fatigue break at the tube sheet link. At Grano, we know real engineering skill goes past heat rules and into structure strength. We fix more than basic plans to stop the main cause of these breaks. This close look will cover the mechanical facts of FIV. It will also show the better fix that turns noisy, break-risk exchangers into steady, long-run tools: The Helical Baffle Design.

Why Does the Vibration Problem Exist? The Design Flaw

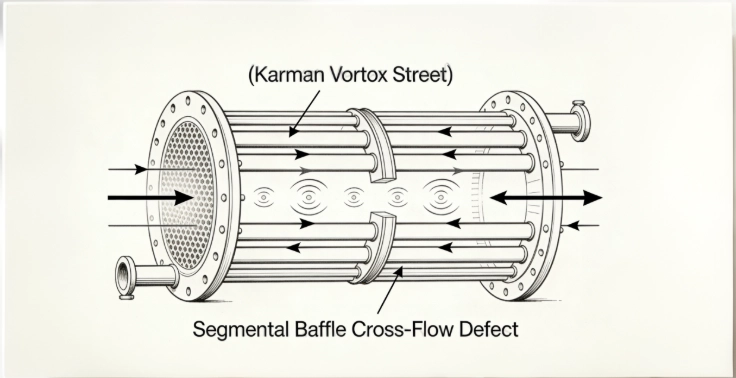

The chance for harmful shaking comes from the common but weak Traditional Segmental Baffle (bow-cut baffle) design.

1. The Segmental Baffle Flow Defect

A baffle’s main job has two parts. It holds up the long, thin tubes. It also sends shell-side fluid over the tube bundle to raise heat transfer speed. But the usual segmental baffle turns fluid in a way that costs a lot in mechanics. With big, half-circle cuts, these baffles make shell-side fluid change path often. This leads to a harmful Cross-Flow pattern.

- The fluid must go almost straight across (sideways) the tube bundle before it turns at the next baffle.

- This strong, fast flow hit makes a big mechanical push force that hits the tubes from the side.

In simple terms, the old design makes fluid hit and shove the tubes over and over, instead of leading it smoothly.

2. The Karman Vortex Street (KVS): The Aeroelastic Instability

The key way FIV works is called Karman Vortex Street (KVS). It is a type of air-flow unsteadiness.

- When fluid goes over a wide shape (like a heat exchanger tube) at a set speed, the fluid can’t follow the curve well.

- Instead, swirls of fluid break off one by one from the top and bottom of the tube.

- This back-and-forth break-off makes changing pressure across the tube’s width. It creates a repeating, up-and-down lift force that goes against the flow path.

When the speed of this swirl break-off gets close to or matches the tube’s own shake speed (or the bundle’s), it hits resonance. The fluid then shakes the tubes at their own speed. This makes the shakes much bigger and harmful. Such resonance can soon go past the metal’s strength and hold limits.

3. The Unstable Span: Insufficient Tube Support

Another reason for FIV is the limit from baffle gaps. Tubes need support often to keep their shake speed high (that is, firm). But gaps must be wide enough to cut shell-side pressure loss.

- In segmental baffle plans, tubes get support only at set, wide spots.

- The open length of tube between baffles, the free span, works like a guitar string. A longer, slimmer string has a lower shake speed. This makes it easy for the low-speed swirl break-off (KVS) to start resonance.

If the baffle gap (tube span) is too wide, the tubes can shake hard with big moves. This leads right to mechanical break.

The Secondary Damages: The True Cost of Vibration

FIV does not often cause instant break. Its harm builds up and hurts over time. It shows in two main, costly break types.

1. Fatigue Fracture at the Tube Sheet

The usual spot for major break is the link between the heat exchanger tube and the tube sheet.

- As tubes shake inside the shell, the top stress point is the fixed join at the tube sheet side.

- The constant bend (flex) of the tube metal puts the material under many-cycle fatigue load.

- After time, often months or weeks in bad resonance, tiny cracks start and grow through the tube wall. This leads to a quick, hard fatigue snap (tube cut) right at the tube sheet side. It right away weakens the tube. This causes fast mix of shell-side to tube-side fluid and system stop.

2. Fretting and Abrasive Wear (Abrasion Leakage)

In the center parts of the tube bundle, the hard shaking makes the tube rub fast against the edges of segmental baffle holes.

- This steady, quick rub takes material from both the tube wall and the baffle hole. The process is fretting wear or scrape.

- Heat exchanger tubes are often thin (under 1.5 mm wall). This repeat rub soon cuts a groove in the pipe wall.

- When the cut goes past a key depth, the tube wall fails. This brings scrape leak and mix. Such break often needs blocking many tubes. It cuts the exchanger’s work a lot.

In jobs that need steady long-run heat transfer, a main goal of Grano products, these FIV break ways mean too much risk and upkeep work.

The Grano Anti-Vibration Solution: Helical Baffles (Spiral Flow Technology)

Grano sees the basic weak points in segmental baffles. So we use better tech to give Shell-and-Tube Heat Exchangers with Helical Baffles (also called spiral flow exchangers). This is a better choice for shake-risk jobs. The special build fixes FIV not by lessening it, but by stopping the main cause.

1. Changing the Flow Regime: Longitudinal Spiral Drive

The top part of the helical baffle plan is how it turns shell-side flow from harmful cross-flow to even, along-tube spiral (helical) flow.

- Instead of making fluid go over the tubes again and again, helical baffles lead fluid next to the tubes. It follows a close spiral path from one shell end to the other.

- This flow way cuts the fast, straight-across flow part that makes strong Karman swirls.

- By turning fluid power into front move instead of side hit, the mechanical push on the tube bundle almost goes away. This makes sure steady, no-shake work.

2. Comprehensive and Continuous Tube Support

The shape of helical baffles gives much better mechanical hold than spread-out segmental plates.

- The helical parts give a half-steady touch line along the tube bundle’s length.

- This plan cuts the real free span of tubes a lot. It makes tubes firmer and raises their shake speed much.

- By lifting the shake speed past the range of swirl break-off speeds, the tube bundle stays safe from FIV resonance. The tubes get “held tight,” stopping the big shakes that cause rub wear and fatigue snap.

3. Data Support: A Dual Benefit

The smart build of the helical plan gives a strong, two-part gain. It fixes both trust and run cost right away.

- Vibration Elimination: FIV gets cut out by build. This makes sure better long-run trust and cuts need for costly tube block or swap.

- Pressure Drop Reduction: By turning the rough, start-stop cross-flow (which makes high flow block) into even, smooth spiral flow, the helical plan cuts rub and rough much. Granofacts show the helical baffle plan can cut pressure drop up to 70% from a usual segmental plan doing the same heat job.

This means a Grano helical baffle unit lasts more and needs less pump power. It turns into real energy save and lower run costs over the exchanger’s life.

Upgrade the Structure, Eliminate the Risk

Fluid-Induced Vibration is not a must-have part of heat exchangers. It is a mechanical break way built into old plans. Using high-upkeep segmental baffles means taking the chance of costly stops, steady noise bother, and final big tube break. If your plant has heat exchanger noise, high pump energy use, and often costly tube fails, it is time to stop fixing the issue and fix the build cause. Grano focuses on planned fixes that raise efficiency and make sure structure long life. By going from the weak segmental baffle to the better Helical Baffle build, you get more than a heat exchanger. You put money in years of steady, quiet, and energy-save heat transfer work. Contact our engineering team today to check your current shell-and-tube plans and learn how the Grano helical fix can stop the hidden killer in your system.

FAQ

Q: Is Fluid-Induced Vibration (FIV) a common problem, or does it only affect poorly manufactured heat exchangers?

A: FIV is a built-in risk in nearly all shell-and-tube heat exchangers with usual segmental baffles, even well-made ones. The risk comes from the mix of run flow speed, fluid weight, and tube shake speed. If shell-side flow speed goes over a key point, shake happens, no matter weld quality. That is why Grano suggests the Helical Baffle plan for high-speed or high-weight fluid jobs.

Q: The Helical Baffle design sounds more efficient. Why isn’t it the industry standard already?

A: The main reason is make trouble. Usual segmental baffles are plain, flat plates easy to cut and put together. Helical baffles need special roll, line-up, and build ways to get the exact spiral shape for smooth flow. The first cost is higher. But Grano thinks the better work, sure no-shake traits, and shown long-run energy save from up to 70% pressure drop cut make the Helical Baffle TCO (Total Cost of Ownership) much better money than usual plans.

Q: If I suspect my current heat exchanger has an FIV issue, what is the first step I should take?

A: The first and key step is to do a pro shake check. This means measuring the size and speed of tube shake and matching the break-off speed (from flow) with the tube’s figured shake speed. If resonance shows, the short fix is often cutting shell-side flow rate (and so capacity). The long, lasting fix from Grano is swapping the usual tube bundle with a better Helical Baffle tube bundle that stops the push forces full.