I. Introduction: The Hidden Cost of “Identical” Heat Exchangers

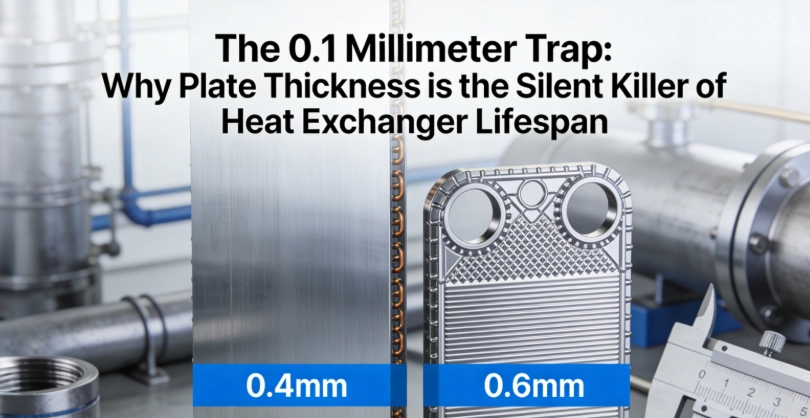

In the busy world of industrial heat transfer, you may run into a strange market oddity: two plate heat exchangers (PHEs) that look like they have the same details—same material, same heat transfer area, and same connection size—yet one costs 20% less than the other. This big price gap usually comes from a hidden trade-off: the maker’s plate thickness. While a quick looker or even a buyer might see just the final product, a usual trick by cheap makers is to quietly cut the plate thickness (for example, using 0.4 mm material instead of the listed 0.5 mm). This small, 0.1 mm difference is almost impossible to spot with the bare eye, yet it can badly shorten the unit’s working life and greatly raise your total cost of ownership (TCO). At Grano, we stand for openness and honesty—mainly when it comes to the key parts that shape our products’ work and lasting power. We know that buying a heat exchanger is a long-run investment, not just a deal for some metal.

II. Beyond the Specs: Why 0.5 mm is Not 0.6 mm

The 0.1 mm gap is not just about less material; it changes the basic physics and mechanics of the plate in a deep way.

1. The Critical Effect of Corrugation

PHE plates are not smooth; they have tricky chevron designs that create swirl and boost the heat transfer rate. This wavy shape comes from a strong-pressure stamping step.

-

Stamping Thinning: When the plate gets pushed into the form, the material stretches out, mostly at the wave peaks and lows (the spots of biggest curve). This step leads to a normal stamping thinning rate. A slimmer starting sheet material ends up with a much weaker lowest thickness after pressing. For instance, a starting 0.4 mm plate could have spots thinned to as low as 0.32 mm, which makes it open to early perforation under light stress.

2. Pressure and Stress Resistance

Plate thickness is the main factor in a PHE’s mechanical strength and top allowed working pressure (MAWP).

-

Pressure Drop: Cutting the plate thickness by only 0.1 mm (say, from 0.5 mm to 0.4 mm) can lower the whole pressure strength by about 20% to 30%. This give-up is extra risky in setups open to pressure changes or water hammer—things that happen a lot in big factory loops, HVAC setups, or sea uses. A slimmer plate cannot take these moving stresses as well, which leads to metal wear, stress breaks, and leaks in time.

III. Corrosion and Erosion: The Protective “Sacrificial Layer”

The top job of plate thickness for long work is its part as a “sacrificial layer” against the steady push of fluid harm.

1. The Buffer Against Erosion

In lots of factory uses, the moving fluid holds small rough bits (like sand, dirt, scale pieces). As the fluid speeds up through the tight plate paths, these bits work like fast sandpaper, always rubbing the plate face. This issue is called erosion-corrosion or impingement corrosion.

-

A 0.6 mm plate gives a 50% thicker guard area than a 0.4 mm plate. This added material slows down the thinning step a lot and gives a way longer work life before the key wall thickness breaks through. In very rough, cloudy places like factory waste water clean-up or earth heat, the work life of a 0.6 mm unit can be double that of a 0.4 mm unit. Such environments put constant wear on the plates, so the extra thickness acts like a shield that lasts through years of tough conditions, preventing early breakdowns that could halt operations and cost a lot in fixes.

2. Time to Pitting Failure

In clear but chemical-tough spots, like those with lots of chlorides or sulfates, pitting corrosion is the main way things fail.

-

Pitting is spot corrosion that makes small, deep pits. The time for a pit to go through the plate wall ties right to the wall thickness. Picking a thicker plate (like Titanium in rough media) gains key time. A thicker plate wall means a longer corrosion penetration time, which gives a needed edge of safety against early, quick failure. In setups where fluids carry salts or acids, this extra time can mean the difference between smooth runs and sudden stops, allowing for planned upkeep instead of emergency swaps.

IV. Matching Thickness to Application: Efficiency vs. Durability

The best plate thickness is a smart choice that weighs heat efficiency, which likes slim plates, against work life, which likes thick plates. Grano’s advice way is to help buyers find the real TCO based on their exact fluid setup.

| Application Type | Recommended Thickness | Primary Benefit | Risk Profile | Ideal for |

|---|---|---|---|---|

| High-Efficiency / Low-Risk | 0.45 mm – 0.5 mm | Top heat move efficiency (k-value). Least material cost. This setup keeps costs down while giving strong heat work in easy conditions… | Shorter work life, lower pressure level… | Clean city water, HVAC chilled/hot water, Low-pressure steam condensation, pure utility circuits… |

| Safety / Industrial Durability | 0.6 mm – 0.7 mm | Longer work life (10+ years), better hold against pressure jumps. This build stands up to hard use… | Slightly lower k-value, higher starting material cost… | Industrial wastewater, Marine cooling (seawater), Geothermal systems, High-pressure chemical processing… |

Picking a 0.6 mm or 0.7 mm plate might lead to a small drop in the whole heat transfer rate (U-value), but the swap is often a decade or more of safe, problem-free work. This cuts out the upsetting, costly, and surprise cost of swapping a broken plate pack too soon. Over time, the thicker choice saves money by avoiding extra downtime and labor, making it a smart pick for busy factories or key systems where stops hurt the most.

V. Grano’s Commitment to Certified Thickness

In a market full of “under-spec” material problems, Grano holds to a plain but firm quality promise: We give what we say.

-

“Full-Gauge” Guarantee: When you buy a 0.5 mm plate from Grano, the material sent is sure to be 0.5 mm Nominal Thickness, sticking tight to field rules and material limits. We flat-out say no to “under-gauge” or “down-spec” materials to fake lower prices and trick buyers. This means every plate meets the mark from start to finish, building trust in our gear for years of steady use.

-

Engineering Consultation: Our group aims at engineering fixes, not just moving boxes. We team up with buyers to check their fluid kind, pressure turns, and wanted work life to pick the right, true plate thickness needed to hit their TCO and safety goals. By looking at the full picture, we help avoid wrong choices that could lead to early issues, ensuring the setup fits the job perfectly.

VI. Conclusion: Buy a System’s Longevity, Not Just Sheet Metal

When picking a plate heat exchanger, keep in mind that you are not just getting sheet metal; you are putting money into the structural strength and lasting power of a key system part. The small-looking 0.1 mm cut in plate thickness is a risky pit that swaps a tiny front material save for a huge hidden cost in early breakdown, surprise stop time, and swap costs. Pick a seller who gives checkable material quality and engineering honesty. Choose Grano for the calm that comes from knowing your heat exchanger is made to last. With our focus on real specs and support, you get gear that works hard without hidden catches, keeping your operations smooth and costs in check over the long haul.

Frequently Asked Questions (FAQ)

-

How does plate thickness relate to the overall heat transfer coefficient (U-value)?

A. A slimmer plate has less heat block, which in theory leads to a bit higher U-value (better heat work). But in real, long factory runs, the U-value gets hit more by fouling resistance (the build-up of scale/deposits) than the plate’s thickness. So, the long-run trust and wear hold from a thicker plate (like 0.6 mm) almost always beats the small 1-2% work gain of a 0.4 mm plate. Over months or years, dirt from fluids takes a bigger toll than the plate’s slimness, so thicker ones keep better flow and heat move in the end.

Q. If my system is low-pressure (e.g., 6 bar) and uses clean water, is a 0.4 mm plate acceptable?

A. Yes, in low-pressure and totally clean-fluid jobs, 0.4 mm or 0.45 mm plates often get picked to max work and cut starting cost. But it is key that this material is a true 0.4 mm nominal thickness and not an even slimmer “down-spec” material. The danger stays in surprise pressure hits (water hammer) or later dirt (like pipe rust), which could cause early failure. In such calm setups, the thin plate saves money up front, but always check for any changes in fluid or pressure that might call for more strength.

Q. How can I verify the actual plate thickness upon delivery?

A. The best check way is to use a set ultrasonic thickness gauge on the smooth edge (shoulder) of a plate before putting together. For the wavy area, a special way or just checking the seller’s Material Test Certificate (MTC) and size check report is needed. Grano gives sure papers proving the full-gauge thickness of the plates sent. This step lets you confirm the specs match what you ordered, avoiding surprises down the line and ensuring the unit performs as expected in your system.