In the demanding world of marine engineering, the dependability of a ship’s cooling setup holds great importance. Ships often depend on seawater or a main freshwater cooling circuit, and the performance of heat exchangers affects the primary engine, backup power units, and the general safety of the vessel. Without proper function in these areas, operations can face serious risks, leading to potential breakdowns or hazards at sea. At Grano, we recognize that even the best heat exchanger performs only as well as the protection it receives. This overview examines the vital function of strainers in sea-based uses and offers practical tips on choosing them to help your ships run smoothly and effectively. By focusing on these elements, operators can avoid common issues and extend the life of their equipment.

1. Why Marine Heat Exchangers Must Be Equipped with Strainers

Marine cooling arrangements usually employ seawater or looped cooling water as the working fluid. Seawater serves as a strong coolant, but it carries dirt and can harm equipment. The sea setting proves tough, and water often holds various unwanted items. These include marine organisms like shells, mollusks, seaweed, and algae. Sediment such as sand, silt, and mud appears in shallow areas or ports. System debris involves rust bits, welding remains, and loose scale from old pipes. All these factors can build up and cause problems if not managed early. Understanding these threats helps in planning better protection for the cooling paths.

The Consequences of Unfiltered Flow

When a heat exchanger, particularly a Plate Heat Exchanger (PHE) with its detailed passages, runs without upfront filtering, the results turn serious. Debris quickly blocks the tight channels in plate groups or the pipes in shell-and-tube models, limiting the water movement. Even some blockage forms spots where heat does not transfer well, raising the cooling levels. As resistance grows, pumps strain more, using extra power and risking uneven operation. Big pieces can scratch the slim plates or wear down tube sets, causing expensive leaks and stops in work. These issues not only raise costs but also delay voyages and affect crew safety. To prevent such outcomes, fitting strainers becomes a key step in setup.

Standard Practice: In ship building, placing a strainer right before the heat exchanger goes beyond suggestion; it forms a basic part of the design needed for safe sea travel. This placement catches problems early and supports steady performance across long journeys.

2. Common Types of Marine Strainers

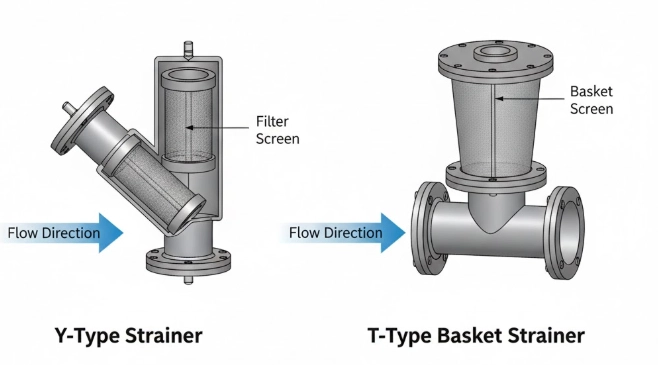

Picking the suitable strainer relies on available room, water speed, and the exact cooling line, whether for the main or support systems. Each type suits different needs based on the ship’s demands and the environment it faces. By matching the strainer to these factors, maintenance stays simple and efficiency holds up over time.

2.1 Y-Type Strainers

Y-type strainers get their name from the basic shape, making them a popular pick for lines with limited space. Their small size fits tight spots without taking much room. Cleaning proves straightforward; one removes a cover or plug to reach the round screen inside. This design works well for support cooling lines, pipes of smaller size, or paths with slower water flow where large amounts of dirt do not appear often. Operators find them easy to handle during routine checks, which keeps the system running without major interruptions. In many vessels, these strainers provide reliable service for less demanding applications, helping to maintain flow without added complexity.

2.2 T-Type / Basket Strainers

Basket strainers use a standing cylinder, called a basket, to catch dirt and hold it. This setup gives much more space for filtering than Y-type models, so they manage larger loads of debris before needing attention. The top-access feature allows quick removal of the basket for washing, saving time during upkeep. Such strainers fit main engine cooling paths, central freshwater units, and big Plate Heat Exchangers where water moves fast and keeping pressure low matters a lot. In high-demand areas, they prevent frequent stops and ensure the cooling works as planned. Their ability to handle heavy use makes them a go-to choice for critical parts of the ship, supporting overall reliability and reducing long-term expenses.

3. The Critical Role of Filters in Plate Heat Exchanger Systems

Plate Heat Exchangers (PHEs) stand as the go-to choice in sea cooling thanks to their small footprint and excellent heat movement rates. Still, the inside layout, with slim spaces between plates usually measuring 2mm to 5mm, leaves them open to particle issues more than traditional shell-and-tube types. A well-placed strainer guards the PHE by offering four main gains. First, it stops solid bits from sticking in plate gaps, keeping water spread even. Second, it cuts down on buildup by pulling out bigger particles, slowing sludge and scale on surfaces. Third, it shields the rubber seals that hold plates together from rough bits that could wear them out. Fourth, cleaner water leads to fewer cleanings of the plate set, raising the ship’s steady work ability. These benefits add up to lower costs and safer runs, making strainers essential for PHE success in tough sea conditions.

In practice, many ship owners see direct improvements after adding proper strainers, as they handle the dirty water common in ports or coastal routes. This setup not only protects the equipment but also aligns with safety rules set by maritime bodies. Over time, the reduced wear means less replacement of parts like plates or gaskets, which saves money and time. For fleets facing varied waters, investing in these filters pays off through better uptime and fewer surprises during operations.

4. Key Selection Points for Marine Strainers

For new ships or updates, Grano suggests paying close attention to four main specs when choosing a strainer. These points ensure the device fits the system’s needs and handles real-world pressures. Getting them right avoids mismatches that could lead to early failures or extra work. By evaluating each, teams can pick options that boost performance and last longer in salty environments.

4.1 Filtration Precision (Mesh Size)

This stands as the top consideration. The screen holes need to measure less than the smallest opening in the heat exchanger to block entry. A common guide says for plate models, set the strainer hole size at half the channel width to avoid any sticking. This balance catches threats without over-restricting flow. In busy systems, matching this precisely prevents clogs that could halt cooling and strain pumps. Engineers often test different sizes in simulations to find the best fit for specific water conditions, ensuring smooth operation across voyages.

4.2 Material Selection

Withstanding rust in seawater setups takes priority. For the main body and screen, materials like top-quality Stainless Steel (316L) or Copper-Nickel blends work best against salt damage and metal reactions. Avoid carbon steel except in sealed freshwater paths, as it corrodes fast in open sea use. Selecting durable options extends the strainer’s life and keeps the whole cooling line safe. Grano experts review material tests to match them with the ship’s exposure levels, providing advice that prevents breakdowns from weak points.

4.3 Pressure Rating

The strainer housing has to endure the planned pressure in the cooling setup, often at levels like PN6, PN10, or PN16 common in sea work. It also needs strength to manage extra push when dirt fills the basket. Building it tough avoids bursts or leaks under load. In high-flow areas, this rating ensures stability even during peak demands, like when the engine runs hard. Checking against system specs confirms the strainer holds up without adding weak links to the design.

4.4 Maintenance Design

On board a vessel, simple access for care proves crucial for keeping things running. Key questions include whether the filter part comes out without fancy tools and if the layout allows work without stopping flow. Duplex models, which switch to a clean side while fixing the dirty one, suit non-stop lines like main cooling. This feature cuts downtime and fits tight schedules at sea. Practical designs let crew handle tasks quickly, using basic gear and following easy steps. Overall, focusing on user-friendly builds reduces errors and supports regular upkeep that keeps the system in top shape.

5. Conclusion

Amid the wide sea surroundings, the strainer acts as a minor part with a huge impact. It traps unwanted bits and safeguards the heat exchanger’s endurance along with the ship’s well-being. For efficient Plate Heat Exchangers or sturdy Tube Heat Exchangers, smart filtering forms the base of good sea planning. Proper choices here lead to fewer issues, steady cooling, and safer trips. Teams that prioritize this see gains in fuel use and part life, turning potential headaches into smooth sailing.

Grano Heat Energy Technology Co., Ltd. serves as a reliable ally for sea heat control. Our broad background in making heat exchangers and matching filter aids lets us give custom guidance for any vessel kind or work setup. From quality swap plates and seals to full cooling kits, we help your group stay on course. With years of serving ships worldwide, we understand the unique challenges of ocean travel and tailor solutions to fit. Whether upgrading old systems or building new ones, our support ensures everything aligns for best results.

Ready to optimize your marine cooling system? Contact Today for a consultation.

Frequently Asked Questions (FAQ)

Q: How often should I clean the strainers on my marine heat exchanger?

A: The schedule for cleaning varies with the water condition around the ship. In deep sea areas, inspections happen less often, but near shores, ports, or streams, check them each day or every week. Watching the pressure change between input and output gauges offers the clearest sign of when to clean. This method keeps the flow steady and spots buildup before it worsens. For vessels in mixed waters, logging these checks helps predict patterns and plan ahead, avoiding sudden halts that disrupt schedules.

Q: Can I use a finer mesh filter to protect my heat exchanger better?

A: It does not always work that way. A tighter mesh grabs more dirt, but it builds pressure faster and blocks up quickly, which might cut water to the exchanger. Choose a size that guards against channel-clogging bits while allowing good water movement. Balancing these keeps efficiency high without over-filtering. In tests, slight adjustments based on local water prove key to avoiding extremes on either side.

Q: Does Grano Heat Energy provide replacement strainers or advice on retrofitting?

A: Yes, we do. Grano focuses on full heat solutions. Our team helps pick filter details to suit your plate heat exchanger type and work needs, guaranteeing fit and strong defense. From stock replacements to custom installs, we cover updates for older setups, drawing on case studies from similar ships to ensure success. This service minimizes risks and maximizes the system’s potential in real use.