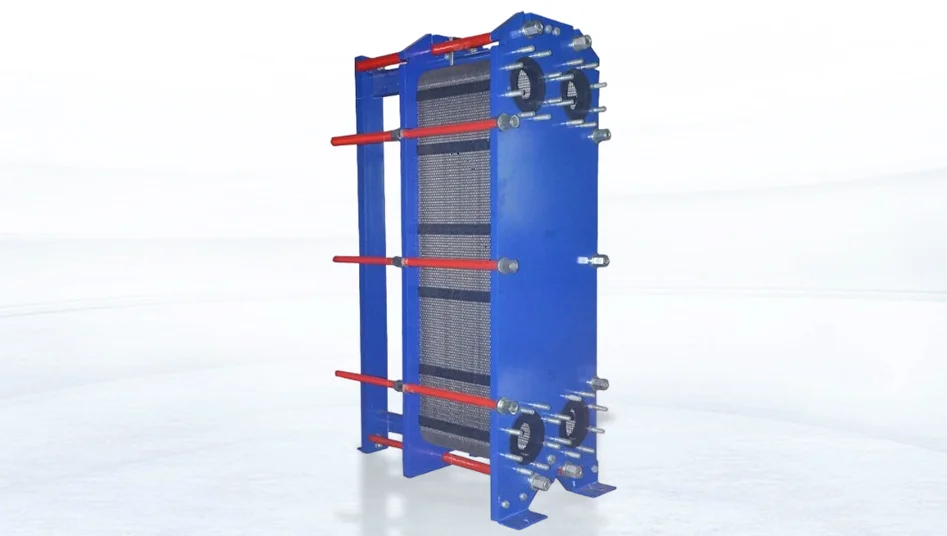

In the tough world of chemical processing, heat exchangers play a key role in handling temperature-sensitive reactions and fluid moves. The plate heat exchanger working principle depends on thin, wavy plates stacked close together. These create side-by-side paths for hot and cold fluids. They boost heat transfer with a big surface area in a small space. This setup works well for efficiency. But it meets special problems in harsh spots like those with acids, bases, and salt mixes. Picking the best materials for the plates and adding strong anti-corrosion plans is not just about how it runs. It’s vital for safety, long life, and saving money. This guide looks at how to handle these picks. It uses common industry tips to mix corrosion fight, heat flow, and money factors.

You might deal with high-pressure mixed flows or rough media. So, knowing how material traits and design parts work together can stop breakdowns. It can also make operations better. We’ll dig into chemical setup details, material choices, design fixes, and care advice. Plus, we’ll touch on side-by-side looks with other options like shell and tube units for wider views.

Chemical Process Conditions for Plate Heat Exchangers

Chemical plants run in rough spots that push any heat exchanger to its edge. Fluids often hold strong rough media. Think sulfuric acid, sodium hydroxide mixes, or brines full of chloride. These can wear down basic materials fast. Then add high heat—often over 150°C. There are also high pressures up to 25 bar. And don’t forget mixed-phase blends like gas-liquid mixes. All this makes things harder.

These things call for top-notch fight against rust and solid build from plate heat exchangers. Unlike easy jobs, chemical work needs plates that stand up to pits, hidden rust, and stress breaks. They must do this without hurting heat pass. For example, in oil refining, fluids go through wild pH changes. Bad material picks can cause leaks or less flow. This raises stop-time costs by thousands each hour.

To show this, think about the gasketed plate heat exchanger advantages in these setups. Their build lets you take them apart easily for cleaning. That’s a big plus in spots where gunk builds up in chemical streams. And they keep high swirl for better heat pass rates. This differs from stiffer builds. So, they fit well for changing loads in batch jobs.

Key Material Properties to Prioritize in Plate Heat Exchanger Design

Picking materials for plate heat exchanger plates rests on a few main traits fit for chemical rough spots. Heat pass makes sure of good swap. But in rough settings, it’s less key than rust fight—the skill to make shield oxide coats that block chemical hits. High pull strength and tire fight are musts for handling pressure ups and downs. Low weight can make the unit lighter for simple setup.

Heat hold is a must. Materials need to fight softening or breaking at top runs. Money and easy get round out the math. Odd mixes raise bills without matching gains in mild spots. Swaps are sure to come. A good heat-pass material might fail in acid touch. So, builders must check these against job details.

From set design rules, best picks boost not just toughness but full system work. They cut energy loss and care needs.

Common Materials for Plate Heat Exchanger Plates in Chemical Applications

Going through the list of materials starts with those tested in chemical jobs. Here’s a simple break-down of top picks. Each fits certain risks.

316L Stainless Steel: Versatile Choice for General Corrosion

A main player in the field, 316L stainless steel stands out with its molybdenum bit. This ups fight against chloride pits—a usual issue in salt mixes. It deals with most chemical media. From weak acids to base streams, it goes up to 200°C and fair pressures. Its low cost and easy shape make it a first choice for wide jobs. But it might not do great in thick strong acids.

In real use, 316L plates keep build strength in mixed flows. They back the tight flow of plate setups.

Titanium (TA2 Grade): Champion for Chloride and Weak Acid Environments

For sea water cool or chloride-heavy jobs, titanium (TA2) gives matchless rust fight with a steady oxide coat. It does best in weak acids and air-rich spots up to 250°C. It has great shape skill for twisty waves. Though it costs more than steel, its long run pays back in sea chemical plants or salt water link-ins.

Titanium’s light build also helps cut full unit weight. This makes it easier to move for add-on setups.

Hastelloy, Nickel Alloys, and SMO 254: Heavy-Duty Options for Extreme Acids and Alkalis

When up against thick sulfuric acid or harsh soda, go to Hastelloy C-276 or Inconel mixes. These nickel-base super metals fight even rust and breaks in pH ends. They hold temps over 300°C. SMO 254, a high-moly austenitic steel, fills the space for urea or nitric acid jobs. It gives top pit fight.

These do great where others drop. But their high price needs proof through full-life checks.

Principles for Selecting Materials: Balancing Media, Temperature, and Cost

Good picking comes down to a full check. Look at the media’s rough level (pH, ion amount). Check run heat/pressure. And weigh money limits. Start with rust maps or lab tests like ASTM G48 for pit chance. For one case, match 316L with temps under 150°C in neutral salts. But step up to titanium for chlorides over 5%.

Add flow moves—swirl areas in plate paths raise wear-rust risks. So, pick harder mixes. On money, figure full own: first cost vs. less stop time. Tools like plate heat exchanger efficiency calculation setups can mix material heat traits. They guess work to make sure picks match energy aims.

Optimizing Plate Structure and Design for Durability and Efficiency

Past materials, plate shape drives wins. Wavy patterns—like chevron or wave lines—push swirl. This ups heat pass by 20-30% over flat faces. It also stops gunk build. Steep-angle patterns make strong mix. They suit thick chemical fluids. But they might raise pressure falls—big in welded plate heat exchanger high pressure cases where joins are fused for no-leak run.

Make flow paths smooth with wider inlets and anti-clog walls to handle mixed slurries. This cuts dead spots that grow rust. For cool jobs, the brazed plate heat exchanger for refrigeration type uses these fixes. It gives small, shake-proof plates that hold flow in cold chemical cool.

Surface Treatments and Anti-Corrosion Measures for Enhanced Protection

Even top materials gain from after-build boosts. Electro-smooth makes faces even to Ra <0.4 μm. This cuts hiding spots where rust starts. It makes clean-in-place easy. Anode coats or PTFE sprays add walls against rough ions. They stretch life in base jobs.

Watch roughness to mix clean ease with flow stick—smoother ends cut scale but might slide in low-flow spots. These boosts work with materials. They grow fight without changing main traits.

Inspection, Maintenance, and Synergy with Sealing Systems

Active care matters a lot. Plan acid clean and pass-keep every three months to fix shield coats. Use nitric-hydrofluoric mixes for steel types. Use no-harm tests like dye leak or sound waves for pit finds. Aim to swap every 3-5 years on thick-loss base.

Plate rust often spreads to seals. It wears rubber parts and causes mix leaks. So, watch team work through full checks. In seal units, this watch keeps the gasketed plate heat exchanger advantages of bend and grow.

Application Cases and Selection Recommendations

Real-job views lock in picks. For sulfuric acid steam-up, Hastelloy plates hold 98% thick at 180°C. They beat titanium in low-air spots. Ammonia water cool picks SMO 254 for urea fight. While salt chloride brines go for TA2 to skip pits.

| Chemical Medium | Recommended Plate Material | Key Considerations | Typical Temp/Pressure |

|---|---|---|---|

| Dilute Acids (e.g., HCl <10%) | 316L Stainless Steel | Cost-effective; monitor chlorides | Up to 150°C / 10 bar |

| Strong Alkalis (e.g., NaOH) | Nickel Alloys (Inconel) | High pH tolerance; fatigue resistance | 200°C+ / 15 bar |

| Chloride Solutions (e.g., NaCl brine) | Titanium (TA2) | Pitting immunity; lightweight | 250°C / 20 bar |

| Oxidizing Acids (e.g., HNO3) | Hastelloy C-276 | Uniform corrosion resistance | 300°C / 25 bar |

This chart makes picks simple. It adds flow numbers from plate heat exchanger efficiency calculation runs.

For odd cases, like high-pressure oil crack, fused builds do well. They match the strength of welded plate heat exchanger high pressure uses.

Comparing Plate Heat Exchangers with Shell and Tube Alternatives

While plates lead in small chemical jobs, shell and tube units give room-grow for big amounts. The shell and tube heat exchanger design calculation looks at wall space and tube setups to best speed. This differs from plate’s built-in swirl. TEMA rules sort them into types like AES for side runs.

A fixed tube sheet shell and tube exchanger brings easy for clean fluids. But it risks heat grow issues. Unlike the bendy U-tube shell and tube heat exchanger advantages in heat ups and downs—simpler clean and no grow joins needed. For oil cool in oil plants, shell and tube with fin tubes do best in low-flow spots. This comes from full shell and tube heat exchanger for oil cooling checks. Though plates win in space and gunk fight.

TEMA types shell and tube heat exchanger rules make sure of fit. But plates often take the win for bend in rough chemistries.

Key Takeaways: Mastering Material and Anti-Corrosion Strategies

Picking materials and anti-rust designs for plate heat exchanger plates in chemicals needs a close eye. Put rust fight over heat pass. Fix shapes for flow. And care hard. By mixing 316L’s wide use with titanium’s strength, and adding boosts like electro-smooth, you stretch run life. You also hold down costs.

Keep in mind, no one pick fits every. Test against your media. Run guesses via flow tools. And check with shell and tube choices for full picks. These plans not only guard runs but lift chemical work to fresh flows.

For those new to this, remember flow math helps a ton. Use simple calcs to see if your pick boosts heat swap without big pressure hits. In chem labs or big factories, these steps scale up fine. They fit small tests or huge lines. And when pitting shows, act fast. A small pit grows to big trouble. Tools like sound checks spot it early. Swap plates before they fail. This cuts risks big time.

On the flip side, don’t over-spend on fancy metals if basic ones work. Balance is key. For mild salts, 316L does the job cheap. Save alloys for real threats like strong acids. This smart spend keeps budgets tight. It also frees funds for other plant needs.

In end, strong anti-corrosion ties all together. From pick to care, each step builds a tough system. Chemical work thrives on this. It turns rough jobs into smooth ones. And that’s what keeps plants humming day in, day out.

FAQ

A:What factors should be prioritized when selecting materials for plate heat exchangers in corrosive chemical environments?

Q:Prioritize corrosion resistance over thermal conductivity. Assess media corrosiveness (pH, chlorides), temperature, and pressure using corrosion maps or ASTM G48 tests. Choose materials like titanium for chlorides or Hastelloy for strong acids, balancing cost via lifecycle analysis.

A:How can surface treatments and maintenance extend plate heat exchanger lifespan?

Q:Electropolishing (Ra <0.4 μm) and coatings like PTFE reduce pitting and fouling. Regular acid cleaning (e.g., nitric-hydrofluoric every 3-6 months) and non-destructive testing (dye penetrant, ultrasonic) detect issues early. Replace plates every 3-5 years in corrosive conditions.

A:When should plate heat exchangers be chosen over shell and tube designs in chemical applications?

Q:Choose plate heat exchangers for compact design, high efficiency, and easy cleaning in fouling-prone or batch processes. Shell and tube designs suit large-volume, clean-fluid applications with less maintenance flexibility. Evaluate based on process scale and fouling risk.