How Plate Heat Exchangers Improve Thermal Efficiency in Daily Use

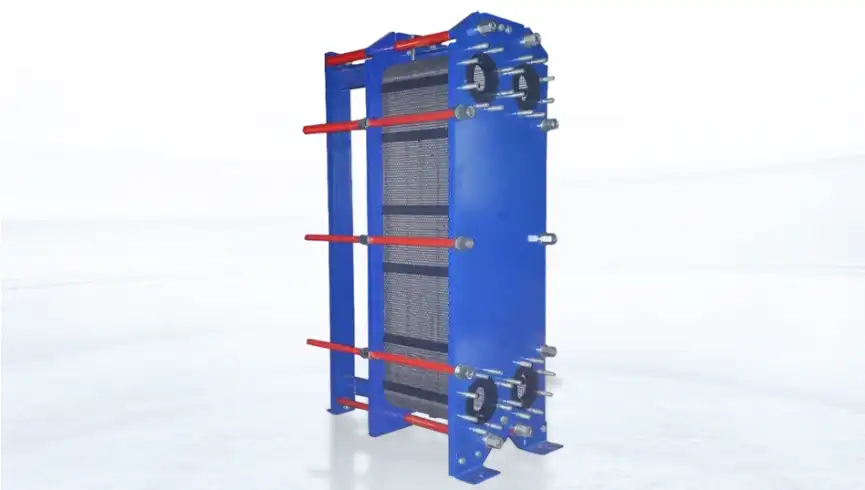

Plate heat exchangers, like the ones made by Grano, are known for their amazing knack for moving heat efficiently in a small and flexible setup. These tools are popular in fields such as HVAC, chemical work, and food making because of how well they perform and adjust. With a special build, rough fluid movement, and simple upkeep, Grano’s plate heat exchangers offer great results compared to older systems like shell-and-tube kinds. This piece looks into why these exchangers shine, ways to make the most of them in everyday tasks, the perks of fully welded types, and important tips for picking the best model for your needs. Plus, we’ll point out why a dependable supplier like Grano is key to lasting performance and toughness.

What Makes Plate Heat Exchangers More Efficient Than Other Types?

Compact Design Boosts Heat Transfer Area

Grano’s plate heat exchangers have a pile of wavy plates that create many paths for fluids. This layout greatly expands the area for heat swapping in a tiny space. Their small build lets them slip into narrow spots while still giving awesome heat results. When you look at bigger setups like shell-and-tube exchangers, Grano’s tight models work better in less room. This makes fitting them into current systems a breeze without losing power.

Turbulent Flow Improves Heat Exchange

The bumpy surfaces on Grano’s plates aren’t just for looks. They do an important job. These bumps make the plates stronger and stir up the fluid flow. This rough movement boosts heat swapping by breaking up the still layer that builds up in calm flows. Small touch points, spread evenly thanks to the crossed bump design, make the fluid swirl. As a result, you get a super good heat transfer speed. That’s why Grano’s exchangers work so well.

Less Fouling Maintains Long-Term Efficiency

Fouling happens when junk builds up on heat transfer spots. It can slow things down over time. But Grano’s plate heat exchangers are built for easy taking apart, cleaning, and fixing. This cuts down on fouling troubles compared to other setups. Their handy design makes quick checks and care simple. So, there’s less time wasted. And they keep working well for a long while.

How Can You Optimize a Plate Heat Exchanger in Daily Applications?

Proper Sizing Avoids Energy Loss and Pressure Issues

Picking the right size for a Grano plate heat exchanger matters a lot for top results. A too-small unit won’t handle the heat needs. A too-big one wastes power. Experts must look closely at things like flow speed, temperature gaps, and pressure caps. When done right, a system with Grano’s exchanger runs smoothly. And it doesn’t cost extra for no reason.

Routine Cleaning Sustains Performance

Even with rough flow cutting down on buildup, dirt can still pile up over time. Long use might cause crust on plates or blocked paths, especially with messy fluids. Cleaning often stops these problems from hurting performance. Grano’s builds usually make taking apart easy. So, upkeep is no big hassle. And the system stays in good shape.

Monitoring Inlet Temperatures Detects Problems Early

Keeping an eye on temperatures at the start and end of Grano’s exchangers is a wise move. It helps workers notice issues fast. Things like smaller temperature changes or quick jumps might mean trouble. Maybe a gasket is worn out or there’s a leak inside. Rust on plates could make holes, letting fluids mix. Spotting this early with temperature checks means quick fixes. And that stops bigger messes.

Why Should You Consider Fully Welded Plate Heat Exchangers?

Welded Design Handles High Pressures and Harsh Fluids

For jobs with strong pressure liquids or stuff that eats away at things, Grano’s fully welded plate heat exchangers are a great pick. Unlike models with gaskets that might break down in tough spots, welded ones stay tight for a long time. They do well in many uses, like HVAC, chemical tasks, and metal jobs, thanks to their solid make.

Durable Sealing Reduces Maintenance Needs

Grano’s fully welded exchangers use few or no gaskets at all. This cuts the chance of seal breakdowns. So, there’s less need for fixes and lower costs over time. Sure, some buildup on plates might need a clean now and then. But the tough welded build keeps those issues small. You can count on steady work from them.

Compact Size Fits Tight Spaces

Just like the gasketed ones, Grano’s fully welded exchangers take up little room. This makes them awesome for setups with not much space to spare. Their tiny size doesn’t mean less power. So, they’re a flexible choice for all sorts of work fields.

How Do You Choose the Right Plate Heat Exchanger for Your Needs?

Assess Fluid Properties and Operating Conditions

Knowing your fluids is super important before choosing a Grano plate heat exchanger. Are they thick? Do they wear things down? Do they get dirty easily? Think about the working pressures and heat levels too. Grano’s exchangers can take pressures up to 25MPa and heat up to 200°C. Stuff like stainless steel, titanium mix, or carbon steel gets picked based on these details. That ensures they last and work well.

Evaluate Space and Installation Requirements

Places for setting up vary a lot. Some are tight HVAC rooms, while others are open chemical plant areas. Grano’s small exchangers are a huge plus here. They fit into different spots with ease and still work great. Their little size makes adding them to new or old systems pretty simple.

Plan for Future Scalability and Maintenance

Your work needs might grow with more output or changing seasons. Grano’s flexible designs let you add plates when needed. This adaptability means your money stays well spent over the years. Easy upkeep also helps keep things reliable and ready for changes down the road.

What Role Does a Trusted Supplier Play in Your Efficiency Goals?

Expert Support Tailors Solutions to Your Needs

A solid supplier like Grano does more than just sell gear. They give helpful know-how to shape answers for your exact setup. Whether it’s figuring out heat needs or helping set things up, their guidance makes sure everything runs great from day one.

High-Quality Manufacturing Ensures Durability

Bad materials or sloppy building can cause early breakdowns, even with a good plan. Grano picks top-notch stuff like stainless steel, copper, aluminum, titanium, or nickel. These are chosen to fight rust and carry heat well. Tight quality rules make sure their exchangers hold up in rough settings. You can trust them to last a long time.

FAQ

Q1: What industries use plate heat exchangers?

A: Grano’s plate heat exchangers are common in heating, bathing, air conditioning, metalworking, hydraulics, chemicals, pharmaceuticals, food, and other areas.

Q2: Are they easy to maintain?

A: Yes, Grano’s exchangers are straightforward to take apart, clean, and mend, especially when compared to shell-and-tube kinds.

Q3: Can they handle high temperatures?

A: For sure, they work at heat levels up to 200°C, based on the material used.