In the world of industrial thermal management, the Plate Heat Exchanger (PHE) is a workhorse known for its high efficiency and compact design. However, operators often encounter a silent performance killer: excessive pressure drop.

When the pressure drop across your PHE rises significantly above the design value, it is rarely just a sign of normal aging. It is a critical indicator that something is wrong with the flow dynamics. Ignoring this issue can lead to reduced flow rates, pump cavitation, increased energy consumption, and eventually, unscheduled downtime.

At Grano, we have spent over a decade helping clients worldwide diagnose and solve these hydraulic challenges. In this guide, we will explore why pressure drop spikes occur, how to troubleshoot them like an engineer, and when it’s time to replace your plates or gaskets.

Why You Cannot Ignore High Pressure Drop

Pressure drop (ΔP) is the energy lost as fluid moves through the heat exchanger channels. While some pressure drop is necessary to create the turbulence that ensures high heat transfer, abnormal pressure drop is a red flag.

The Hidden Costs of High Pressure Drop:

-

Energy Waste: Your pumps must work harder to overcome the resistance, directly increasing electricity bills.

-

Process Instability: In HVAC or chemical processes, reduced flow on the hot or cold side can lead to failure in reaching target temperatures.

-

Equipment Damage: Excessive backpressure can force pumps off their Best Efficiency Point (BEP), leading to vibration, seal failure, or impeller damage.

Common Symptoms of Excessive Pressure Drop

Before opening the unit, operators usually notice the following signs:

-

Drastic Flow Reduction: The process fluid flow rate drops significantly below the setpoint.

-

Rising Differential Pressure: The gauge reading difference between the Inlet and Outlet ports increases steadily.

-

Poor Heat Transfer: The outlet temperatures are no longer meeting specifications (e.g., cooling water isn’t cooling enough).

-

Pump Overload: Amperage readings on the feed pump motor spike.

Root Causes: Why is My Pressure Drop Too High?

1. Fouling and Clogging (The #1 Culprit)

The most common cause is the accumulation of deposits inside the plate channels. Depending on your media quality, this can be biological growth (slime), scaling (calcium carbonate), or particulate blockage.

As the effective channel width (dplate) narrows due to fouling, the velocity increases, and friction rises exponentially.

Table 1: Impact of Fouling on Pressure Drop (Simulation Data)

| Fouling Type | Reduction in Channel Gap | Estimated Pressure Drop Increase | Effect on Heat Transfer (U-Value) |

|---|---|---|---|

| Light Silt | 5% | +10-15% | Minimal Impact |

| Bio-film (Slime) | 10% | +25-40% | Significant Drop (-20%) |

| Hard Scale (CaCO3) | 20% | +50-80% | Severe Drop (-40%) |

| Particulate Blockage | >30% (Local) | >100% (Spikes) | Flow Maldistribution |

Data Source: General industry simulations for standard chevron patterns.

2. Incorrect Plate Arrangement

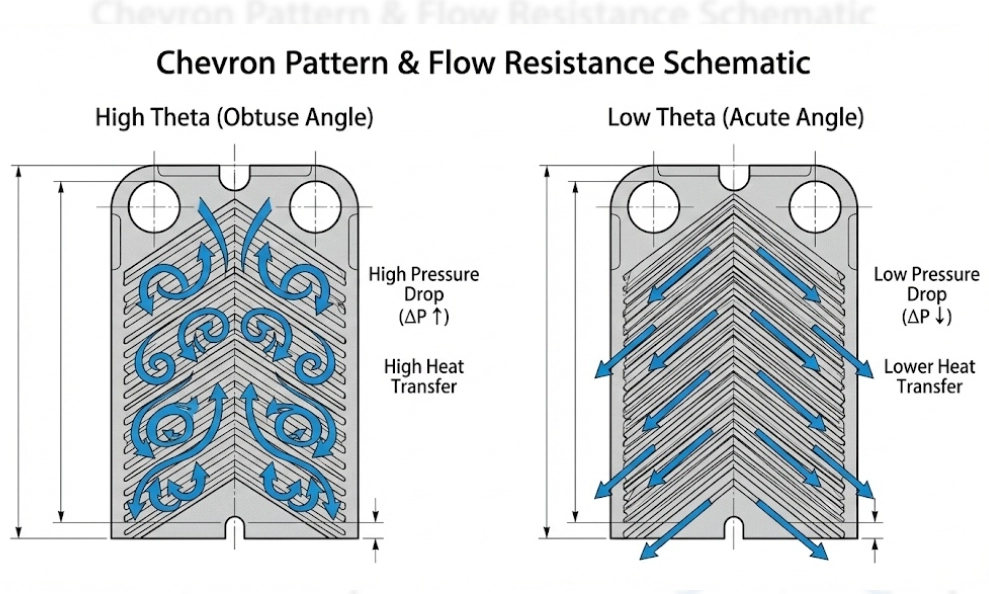

PHEs often use a mix of plates with different pressing angles—High Theta (obtuse angle) for high heat transfer/high pressure drop, and Low Theta (acute angle) for lower pressure drop.

The Mistake: During maintenance, if a technician accidentally installs too many “High Theta” plates or mixes up the A-plate and B-plate sequence, the channel geometry changes. This can inadvertently double the hydraulic resistance.

3. Design Mismatch

Sometimes the hardware is fine, but the application has changed. If the current flow rate exceeds the original design capacity by even 20%, the pressure drop can rise by nearly 45% (since ΔP∝Flow2).

Engineer’s Troubleshooting Checklist

Before you incur the cost of disassembling the heat exchanger, follow this logic path used by Grano engineers:

-

Step 1: Data Verification

Compare the current gauge readings against the original specification sheet.

Check if the mass flow rate has been increased recently.

-

Step 2: Check the “Cold” Side vs. “Hot” Side

Is the pressure drop high on both sides or just one? If it is only on the cooling water side, it is likely debris or biological fouling.

-

Step 3: Pump & Strainer Check

Crucial Step: Check the inlet strainers/filters. A clogged filter is often mistaken for a clogged heat exchanger.

Verify the inlet pressure is stable.

-

Step 4: Backflushing (First Aid)

If the unit is clogged with loose debris, reversing the flow direction (backflushing) can sometimes dislodge the blockage without opening the unit.

Real-World Case Study: The HVAC Cooling Crisis

Scenario: A commercial building in Southeast Asia reported a high-pressure alarm on their chiller system’s condenser side. The flow rate of cooling water had dropped by 30%, causing the chiller to trip.

Investigation:

-

Design $ \Delta P $: 50 kPa.

-

Actual $ \Delta P $: 120 kPa.

-

Inspection: Upon opening the PHE (a generic model), the maintenance team found the inlet ports were 60% blocked by small plastic bits and algae from the cooling tower. Additionally, the gaskets were hardened and flattened, which had caused the plate pack to be over-tightened to stop leaks, further compressing the channels.

The Solution:

-

Chemical Cleaning: The plates were pressure washed and soaked in a weak acid solution to remove the algae.

-

Replacement Parts: The team contacted Grano. Although the original unit was from a major European brand, Grano supplied compatible replacement gaskets (EPDM) and a few replacement plates within 48 hours.

-

Result: After reassembly with new gaskets and cleaned plates, the pressure drop returned to 48 kPa, and the chiller efficiency was restored.

When to Repair vs. When to Replace

Cleaning solves fouling, but physical damage requires replacement. You should consider replacing components if:

-

Deformation: Plates are permanently deformed due to over-tightening or water hammer. Distorted plates disrupt the flow channel gap.

-

Corrosion: Pitting corrosion can cause internal cross-contamination. If you see pressure equalizing between the two media, you likely have a plate perforation.

-

Gasket Failure: If gaskets have lost their elasticity (taking a “compression set”), you cannot reseal the unit properly without over-compressing the plate pack, which ironically increases pressure drop.

At Grano, we provide high-quality alternatives for plates and gaskets compatible with brands like Alfa Laval, GEA, APV, and Tranter. Our parts ensure your system runs at original design specifications without the premium price tag.

Summary

High pressure drop in a Plate Heat Exchanger is a symptom, not the disease. It typically points to fouling, debris blocking the inlet, or improper assembly. By adopting a systematic troubleshooting approach—checking strainers first, validating flow rates, and inspecting for fouling—you can restore system efficiency.

Remember, a PHE is only as good as its maintenance. Regular cleaning and timely replacement of aging gaskets are the keys to long-term stability.

Need replacement plates or gaskets to fix your pressure drop issues? Contact Grano today for a quote on high-quality, compatible spares for your heat exchanger.

FAQ

Q: Can I reduce pressure drop by just loosening the tightening bolts on the heat exchanger?

A: No, this is dangerous. Loosening the bolts increases the distance between plates (the A-dimension), which might slightly reduce pressure drop, but it will almost certainly cause external leakage or internal mixing of fluids. The plate pack must always be tightened to the specific dimension defined in the user manual.

Q: How does the “Chevron Angle” affect pressure drop?

A: The pattern on the plate is called the chevron. A High Theta (obtuse) angle creates high turbulence and high heat transfer but results in higher pressure drop. A Low Theta (acute) angle allows fluid to pass through more easily, resulting in lower pressure drop but lower heat transfer efficiency. Mixing these incorrectly during assembly is a common cause of pressure issues.

Q: My pressure drop is high, but the plates look clean. What else could it be?

A: If the plates are clean, check the port holes. Sometimes, a large object (like a stone or piece of gasket) blocks the inlet port, restricting flow before it even enters the plate channels. Also, verify that the flow rate hasn’t been increased beyond the unit’s design limit by a new, oversized pump.