I. Introduction

Many customers face a common challenge. They simply know they need cooling or heating. Yet, when asked about flow rates or heat loads, they often cannot provide clear answers. This situation creates uncertainty in selecting the right equipment.

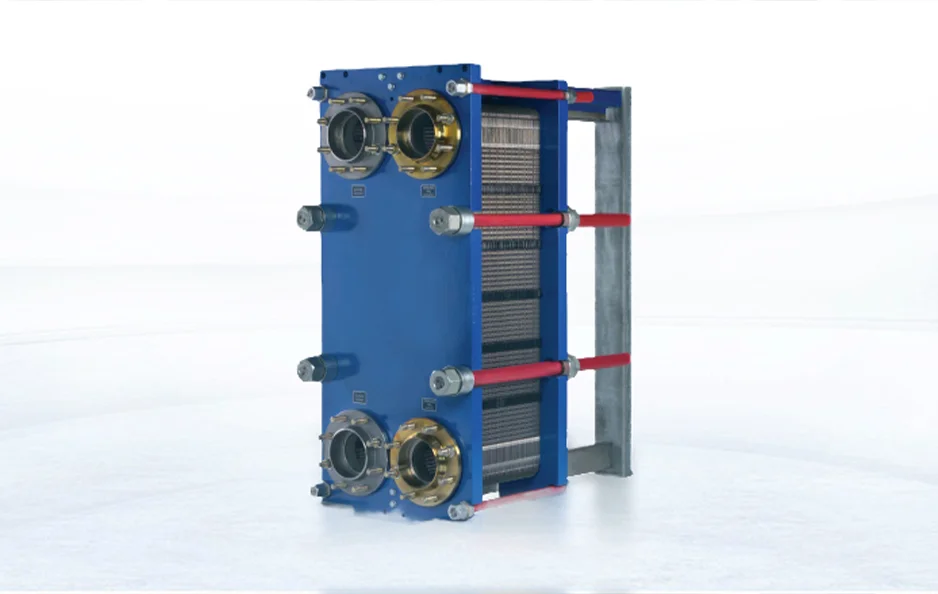

At Grano, we go beyond being just a manufacturer of plate heat exchangers. We act as your trusted process advisor. Even with vague requirements, our team uses smart methods to guide you toward the best solution. This approach, known as No-Parameter Selection, helps turn confusion into confidence.

To bridge this gap, we start by gathering essential details in a structured way. This leads us naturally into the first step of our process.

II. First Step: Gather the Core Three Elements Like a Detective

We begin by asking key questions to uncover basic facts. These form the foundation for our Reverse Engineering Design process.

What is the medium? We need to identify if it is water, oil, or wastewater with fibers. This choice determines whether to use standard plates or wide-channel ones. For instance, dirty fluids often require wider gaps to prevent clogging.

What is the target temperature? Tell us the starting and ending degrees for the fluid. These numbers help us calculate the necessary heat load accurately. Without them, we rely on estimates, but your input makes it precise.

How thick are the existing pipes? If flow rates are unknown, pipe size and pump labels can help us estimate. This reverse calculation ensures the system fits your setup seamlessly.

Once we have these core elements, we move forward. But details alone are not enough. We must also consider hidden limits that affect performance.

III. Second Step: Uncover Hidden Constraints — Pressure Drop

After securing the basics, we dig deeper into system compatibility. Pressure drop is a critical factor that many overlook.

Why check the pump? Any heat exchanger must align with your current pump’s power. A mismatch could raise energy costs sharply. We examine pump specs to avoid such issues.

The balancing act: If you do not know the allowed pressure drop, we draw from industry know-how. For liquid applications, we suggest 20–80 kPa as a practical range. This keeps things energy-efficient while maintaining strong performance.

With pressure in mind, our design stays practical. However, optimization does not stop there. We use advanced tools to compare options thoroughly.

IV. Third Step: Use Simulation Software for Multiple Scheme Comparisons (Avoid Focusing Solely on Area)

Now that constraints are clear, we employ technology to refine choices. Simulation software allows us to test various setups without real-world trials.

The area pitfall: Quoting based only on heat exchange area is misleading. Devices with the same area can vary in efficiency by 20–40% due to channel designs. We look beyond surface numbers.

Scheme refinement: Our engineers calculate combinations of high-efficiency plates (H plates) and low-resistance ones (L plates). This identifies the option that cuts running costs most effectively. For more on our Pressure-Drop Optimized designs, explore our semi-welded plate heat exchanger solutions.

These comparisons ensure a tailored fit. Yet, we also think ahead to long-term needs, making sure the system evolves with your operations.

V. Fourth Step: Anticipate the Future — Maintenance and Expansion

Building on optimized designs, we focus on durability and flexibility. This step addresses real-world wear and growth.

Clog prevention tips: For poor water quality or dirty media, we recommend 8–16 mm wide gaps. These extend cleaning intervals and reduce downtime significantly.

Scalable design: We leave extra space in the frame. When production ramps up, you can upgrade by adding just a few plates. This saves money and hassle over time.

By planning for the future, we create lasting value. In essence, our method transforms vague ideas into reliable systems.

VI. Conclusion

Lacking parameters is no barrier. Just share the problem you aim to solve. Grano’s engineers handle the intricate math and details. Visit our company website to connect with experts today. For specialized needs, check our contact page or explore gasketed options at gasketed plate heat exchanger.

To further illustrate our No-Parameter Selection process, consider this simple table comparing typical scenarios:

| Scenario | Core Element Gathered | Pressure Drop Recommendation | Plate Type Suggested |

| Cooling Clean Water | Medium: Water; Temps: 80°C to 40°C; Pipe: 2-inch | 20-40 kPa | Standard Plates |

| Heating Oily Fluid | Medium: Oil; Temps: 20°C to 100°C; Pump: 5 kW | 40-60 kPa | Wide-Channel Plates |

| Wastewater Treatment | Medium: Fibrous Wastewater; Temps: 60°C to 30°C; Pipe: 4-inch | 50-80 kPa | H Plates with L Combination |

Here are key benefits of our Reverse Engineering Design in bullet points:

-

Starts from basic inputs to build a full picture.

-

Reduces guesswork, saving time and costs.

-

Ensures compatibility with existing infrastructure.

-

Optimizes for energy use and longevity.

FAQs:

Our process often raises questions from clients new to this. Below, we address some common ones based on frequent searches.

Q1: What if I only know I need cooling for my factory process?

A: No worries. Share the basic goal, like cooling a fluid in your setup. We will ask simple questions about the medium and temperatures. From there, our team uses Reverse Engineering Design to estimate flow and loads. This leads to a precise plate heat exchanger recommendation without needing exact parameters upfront.

Building on that, many wonder about costs and efficiency.

Q2: How does pressure drop affect my energy bills?

A: Pressure drop measures resistance in the system. High drops force pumps to work harder, increasing electricity use. In our Pressure-Drop Optimized approach, we target 20-80 kPa for most liquids. This balance keeps operations smooth and bills low. Simulations help us fine-tune for your specific pump.

Finally, scalability is a top concern for growing businesses.

Q3: Can I expand the heat exchanger later without buying a new one?

A: Absolutely. We design frames with extra capacity. If your needs grow, add plates easily. This modular setup, especially with wide-gap options for dirty media, supports future upgrades cost-effectively. It’s a smart way to invest in long-term flexibility.