Introduction

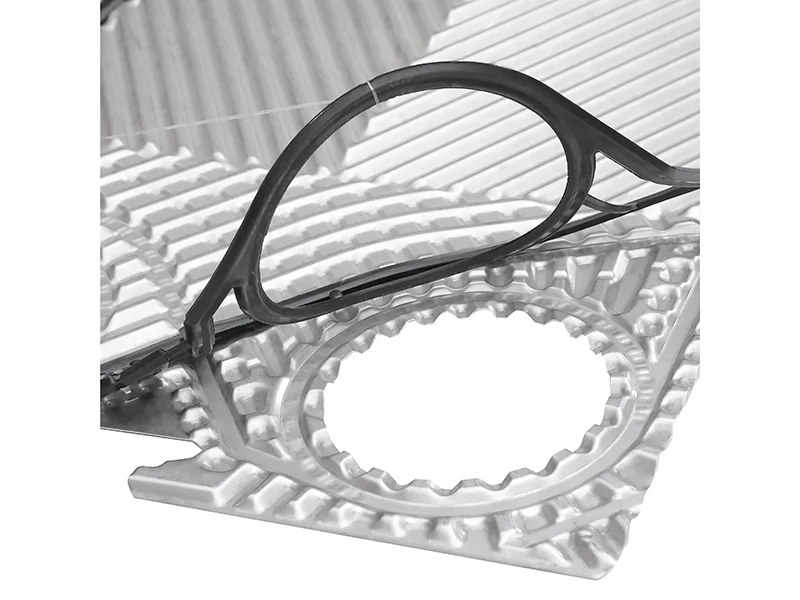

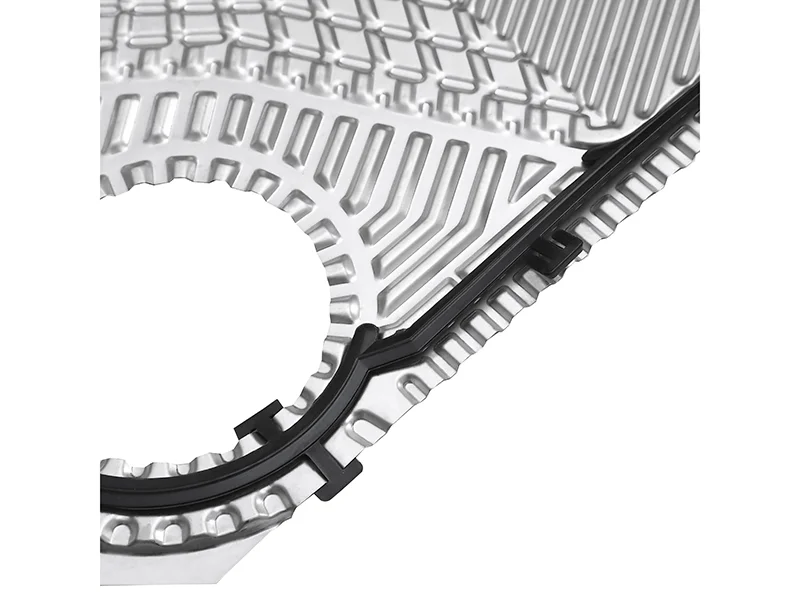

As you deal with the tricky parts of keeping sanitary heat transfer systems in food processing, picking the right sealing parts becomes super important for ensuring your products stay pure and your work runs smoothly. Food-grade heat exchanger gaskets act as key barriers that stop leaks while helping heat move well in places where cleanliness matters most. These special seals are built to handle tough conditions, like sudden temperature changes and harsh cleaning fluids, all while following strict safety rules. Picture yourself running a dairy plant where every seal must survive steam cleaning without ruining the freshness of your milk batches—these gaskets make that happen by creating a strong, safe connection between plates in heat exchangers.

In this case, you might want to check out options from a trusted company like Grano, known for making high-quality heat transfer parts that put food safety and toughness first. With years of know-how, they stand out by offering choices you can adjust to fit your needs, whether you work with acidic drinks or drug-making fermentations. Their team of experts focuses on new materials that last longer, cut downtime, and boost efficiency—think of it as teaming up with people who really get the stress of your job and provide parts that work hard in real situations. This caring approach, from the first talk to ongoing support, ensures you get not just a gasket, but a dependable partner for your production line. By adding these advanced seals, you can grow your operations with confidence while lowering risks.

This article dives into the main needs for these gaskets, looks at common materials with their benefits, explains why they are a must in food work, and shows real situations where they shine. Through this, you will pick up tips to improve your systems effectively.

Essential Requirements for Food-Grade Gaskets

Moving from the basic role of these seals, you need to think about the strict rules that decide if they fit for food use. Following regulations forms the base, as these gaskets must match FDA guidelines under 21 CFR 177.2600 or EU rules like EC 1935/2004. These standards keep extractable substances below 10 mg/dm² and ban heavy metals, making sure no harmful stuff seeps into your processed liquids. You get this through outside checks that give clear records, letting you easily add them to your quality plans.

Beyond rules, material strength matters a lot. You need gaskets that stay non-toxic and odor-free to avoid changing the taste or smell of your products, like fruit juices or dairy items. Also, they must resist damage from cleaning agents like alkaline mixes or chlorine-based cleaners. This toughness supports many sterilization rounds without breaking down, keeping the seal strong over time.

Performance under work pressure completes the needs. You require thermal stability to manage temperatures from -20°C to 180°C, based on the task, along with good compressibility to hold tight seals despite pressure shifts. These traits together protect your equipment from leaks, which could otherwise cause expensive stops.

Common Food-Grade Gasket Materials and Their Advantages

Building on these needs, the material you choose greatly affects how well your gaskets perform daily. Several options catch attention for their unique strengths, each tackling specific challenges in food processing.

Food-grade EPDM stands out for places with hot water and disinfection. This type handles temperatures up to 160°C, making it perfect for steam cleaning and hot-fill tasks. Its resistance to ozone and UV light adds to its life, possibly cutting replacement needs by 25% in nonstop work. You gain from this in setups where frequent cleaning happens, as it stays flexible without cracking.

Silicone gaskets bring great softness, ideal for handling thick media like dairy products and drinks. With a wide temperature range from -50°C to 200°C, they show low compression set, ensuring steady sealing even after long use. Their non-stick surface makes cleaning easy, reducing leftover buildup and supporting cleanliness in lines processing creams or syrups.

For tougher chemical exposures, special fluorine rubber gaskets offer top-notch resistance to high levels of acids and inorganic oxygen acids, working well between 30°C and 130°C. This suits acidic fermentations, where they last longer and lower upkeep costs with better resistance.

Other types, like hydrogenated nitrile rubber pads, do well against mineral oils, animal fats, and vegetable oils up to 150°C, while also handling H2S in some media. Universal Viton versions manage nonpolar mineral oils and alcohol-containing fuels up to 180°C, adding variety for mixed systems. Nitrile options fit lower temperatures down to -135°C for general oil resistance, and solvent-based EPR variants deal with polar solvents like dilute mineral acids from -20°C to 150°C.

Each material’s benefits—from longer life to easier cleaning—let you pick based on your specific media and conditions, ultimately boosting system performance.

The Imperative for Food-Grade Gaskets in the Industry

With a good grasp of material options, you next see why these specialized gaskets are essential in food work. First, they stop secondary contamination of your media. Regular seals might leak polymers or residues into liquids, encouraging germ growth and risking product safety. By using compliant versions, you remove this danger, keeping every batch pure.

Following hygiene laws comes next. Systems like HACCP and GMP demand clear safety steps, and these gaskets help you follow them with certified materials that simplify checks. You avoid fines and recalls by using seals that meet record-keeping standards, strengthening your work’s reputation.

Plus, they improve equipment care and cleaning ease. Designs that resist sanitizers allow faster clean-in-place routines, cutting downtime by 20-40% during takedown and setup. This ease turns into higher output, letting you focus on making products rather than fixes.

In short, these needs protect your items, meet legal demands, and smooth workflows, forming a full plan for lasting operations.

Typical Application Scenarios

Putting these insights to use, you face many situations where food-grade gaskets excel. In pasteurization and cooling for milk, fruit juices, and beer, they ensure steady performance in plate heat exchangers. For high-temperature short-time methods, seals like EPDM or silicone handle shifts from 4°C to 72°C, promoting even heat spread and preserving flavors without contamination.

In drug-making and fermentation areas, temperature control needs precision. Here, special fluorine rubber options keep stability in bioreactors up to 130°C, supporting pH-balanced processes for probiotics or active ingredients. Their acid resistance helps grow production, minimizing breaks in clean environments.

These examples show how tailored seals solve real problems, from heat shocks in drink lines to chemical exposures in drug making, improving overall reliability.

Conclusion: Leveraging Expertise for Optimal Performance

To finish, these gaskets’ needs and uses highlight their role in lifting your food processing efficiency. From rule alignment to material-specific benefits, they offer fixes that prevent issues and increase productivity. Adjustable features, like quick prototyping for unique needs, further cut ownership costs through reliability and sustainability.

For tailored help, consider reaching out to experts who offer talks, choice advice, or custom engineering. You can connect via email at sales@grano-heat.com or the inquiry form on their site, with answers usually within 24 hours for urgent matters. This support ensures you find the best fit for your setup.

Frequently Asked Questions

Q: What standards must food-grade heat exchanger gaskets meet to ensure safety?

A: These gaskets must comply with FDA rules under 21 CFR 177.2600 or EU standards like EC 1935/2004, limiting extractables and banning harmful substances to prevent contamination.

Q: How do different materials like EPDM and silicone benefit specific food applications?

A: EPDM suits hot water and disinfection up to 160°C for steam tasks, while silicone’s flexibility handles dairy and drinks with temperatures from -50°C to 200°C, easing cleaning in thick media.

Q: Why should you prioritize food-grade gaskets over standard ones in the industry?

A: They avoid secondary pollution, meet hygiene laws like HACCP, and improve maintenance by resisting cleaners, thus enhancing efficiency and reducing risks in production lines.