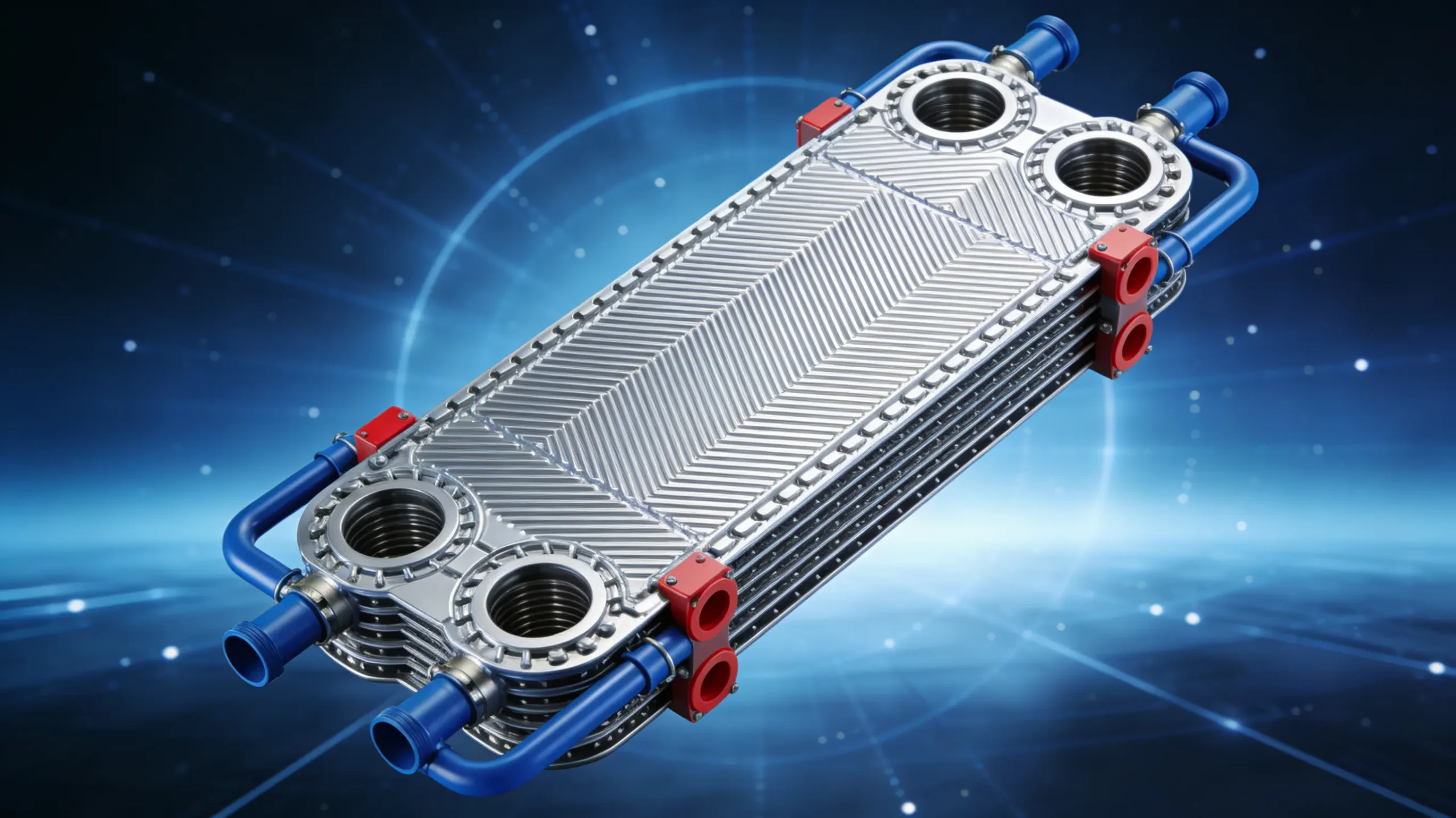

When most buyers or technical staff check out a Plate Heat Exchanger (PHE), they right away look at the specs for “heat transfer area” and “plate material.” This makes sense as a first step, since the plates handle the main job of moving heat from one side to the other.

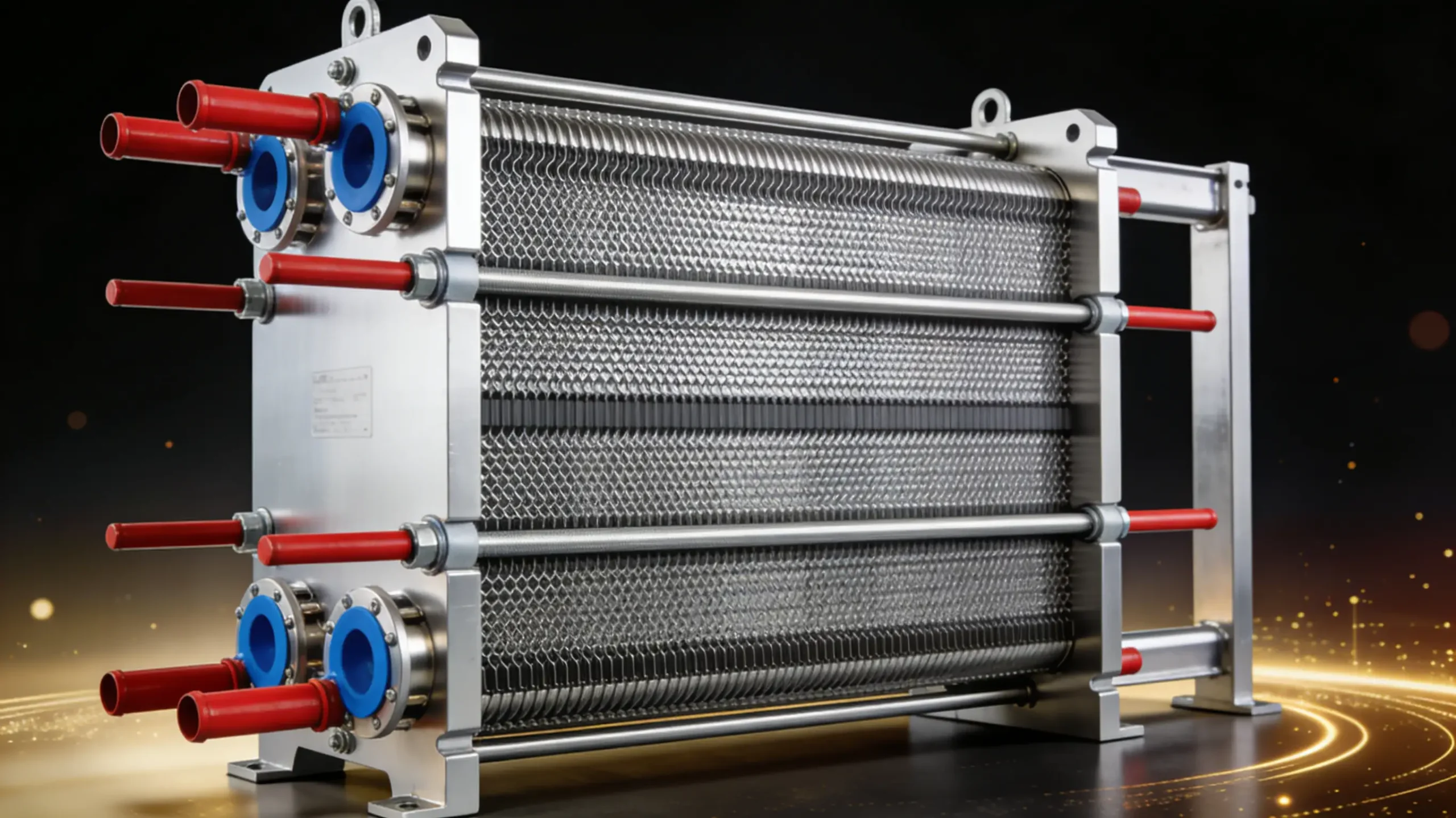

But paying attention only to the plates is much like getting a strong motor and then putting it on a flimsy base. At Grano, we think that the plates may be the core of the setup, yet the frame and interface assembly serve as its basic structure and outer shield.

In this close look, we explain the careful work that goes into Grano’s frame setup and the reasons these less obvious parts really decide if your gear will hold up for five years or a full twenty.

Many people in the field spend time on the visible features, but the hidden elements often make the biggest difference in how long something lasts. For instance, a well-made frame not only supports the plates but also deals with daily stresses that build up over time. This foundation helps avoid early breakdowns and keeps costs down in the long run. Understanding these details can change how you pick equipment for your operations, leading to smarter choices that pay off year after year.

I. The “Pressure Vessel” Mindset: Why Frame Integrity Matters

A widespread idea in the business is to see a heat exchanger as just a basic pipe fitting. In truth, a PHE acts as a sophisticated pressure vessel.

The plates take care of shifting heat, but the frame handles containment. It has to endure huge inner water pressures and the steady pull from the bolts that tighten everything. A frame that lacks strength results in several problems.

Flange Deformation: This causes ongoing leaks that no extra tightening can stop.

Bolt Seizure: It turns routine checks into major tasks that involve cutting parts apart.

Structural Fatigue: This raises the chance of sudden breaks when pressure jumps up.

At Grano, our approach to design sees the frame as the base for safety, making sure each piece goes beyond the usual strength needs.

This focus on solid building starts from the drawing board, where engineers test materials and shapes to handle real-world loads. In busy plants, where equipment faces varying conditions, such careful planning prevents small issues from turning into big expenses. Teams that choose gear with this level of detail often report fewer surprises and smoother workflows, which boosts overall productivity without constant worries about failures.

II. More Than Paint: C5-M Level Corrosion Protection

In tough work settings, outside factors hit the equipment’s exterior as hard as the inner fluids hit the inside. Low-cost PHEs usually apply just one coat of simple rust-proof paint. In a wet workshop or near the sea, that paint starts to chip away in a few months, which lets rust spread through the structure.

The Grano Standard: We apply a step-by-step coating method, often starting with an epoxy zinc-rich primer and finishing with a high-durability polyurethane topcoat.

C5-M Classification: Our frames receive treatment to match C5-M (Marine/Offshore) standards for fighting rust.

The Benefit: This protective layer keeps the frame strong and looking good even in places with sour air from chemicals or lots of salt, holding up for more than ten years.

Such protection goes beyond basic needs by creating a barrier that seals out moisture and harsh elements right from installation. In coastal factories or areas with high humidity, this setup means less frequent touch-ups and more time focused on production. Workers notice how the equipment stays reliable, which builds trust in the system and reduces the need for emergency fixes that disrupt schedules.

III. The Maintenance Revolution: The “Roller Bearing Box”

The bolts that tighten a big heat exchanger hold very heavy loads. On older models, the rubbing between the nut and frame is so strong that taking the unit apart for a clean-up calls for powerful tools and a lot of time from the crew.

The Grano Innovation: We add Roller Bearing Boxes to the key tightening bolts on our bigger sizes.

90% Friction Reduction: Switching from sliding rub to rolling action cuts the effort needed to turn the nut by a huge amount.

Single-Operator Maintenance: One worker with a regular hand tool can usually handle opening even sizable units. This cuts down on staff time and shortens stoppages, which act as a secret drain on the efficiency of work gear.

This smart addition changes how teams approach routine tasks, making them quicker and safer without heavy machinery. In plants where downtime costs money every hour, features like this keep things moving and help meet tight deadlines. Over months of use, the ease of access leads to better upkeep habits, as staff feel less burdened by tough jobs and more able to spot issues early.

IV. Interface Liners: Ending the “Rubber Sleeve” Compromise

The connection point, where the pipe joins the exchanger, is a spot with high risk. If the harsh fluid reaches the steel frame, it will start to break down the frame from within.

The Hidden Risk of Rubber Liners: Lots of makers use rubber covers to protect the openings. They cost little, but rubber wears out, stiffens up, and bends out of shape. Once the cover gives way, the seal at the edge breaks, causing drips and rust on the frame.

The Grano Solution: Metal Flanged Liners We always use Metal Liners (regular or edged types) crafted from the same top-quality stuff as the plates, whether that is AISI 316L, Titanium, or Hastelloy.

Material Consistency: The opening resists chemicals just like the inner plates do.

Permanent Protection: A metal cover does not break down like rubber, so the steel frame stays safe from the working fluid forever.

By choosing metal over softer options, we ensure the whole system holds together under pressure and exposure. This approach fits well in setups where fluids vary in strength, preventing weak spots that could lead to shutdowns. Maintenance records show that units with these liners need far fewer repairs at the joints, saving time and keeping the focus on smooth operations rather than constant patching.

V. Food-Grade Excellence: The Stainless Steel Cladding Option

In areas like food making, drinks, and drug production, cleanliness is a must. A full stainless steel frame is the best choice, but it often costs too much for many budgets.

The Cost-Effective Alternative: Cladding Technology Grano provides a strong Stainless Steel Clad frame. We start with a solid carbon steel inside and cover it with a 2mm–3mm layer of stainless steel for safety.

The Value Proposition: You gain the ability to wash everything down and meet rules from FDA or health codes, yet at a 40% lower cost than a full stainless steel build.

Strength + Beauty: It offers the firm support of carbon steel plus the clean, smooth finish of stainless steel for strict spaces.

This cladding method strikes a balance between toughness and purity, ideal for places where rules demand spotless surfaces but funds are limited. Installers find it easy to set up, and it blends into modern facilities without looking out of place. Long-term, it supports high standards of safety and appearance, which helps companies pass inspections with ease and maintain customer trust through reliable quality.

Conclusion: The Foundation of Your ROI

A heat exchanger ought to be a piece of gear you install and then leave alone. By putting money into the “skeleton”—like the rust-proof layers, the bearing boxes, and the metal connection covers—you are getting more than a device; you are securing twenty years of steady work without headaches.

At Grano, we go beyond selling plates; we offer planned heat systems based on solid building strength. Do not trade the next twenty years for a tiny cut in costs right now.

Looking ahead, this investment in quality parts builds a setup that adapts to changes in your process and grows with your needs. Many users share how their Grano units outlast expectations, turning what could be a short-term buy into a long-term partner. With support from our team, you can tailor the frame features to fit your exact setup, ensuring every dollar spent brings real returns in uptime and efficiency.

FAQ

Q: How do I know if I need a C5-M coating or a standard industrial coating?

A: If your site sits within 5km of the sea, deals with sour gases, or needs regular chemical rinses (such as in food work), you need C5-M protection. For inside spots that stay dry, like air handling systems, our regular strong epoxy layer works fine.

Deciding on the right coat involves looking at your local conditions and how often the gear faces wet or salty air. Our experts can review your setup to suggest the best match, helping avoid overkill or under-protection that might lead to early wear.

Q: Why are metal liners superior to rubber liners in the ports?

A: Rubber liners tend to flow under cold stress and break down from heat. As time passes, they get smaller or split, letting harsh liquids slip past and damage the steel frame behind. Metal liners made of Titanium or 316L create a lasting wall that does not wear out and lasts as long as the plates.

This durability means fewer worries about hidden corrosion that creeps in over years. In fluid-heavy operations, where leaks could spoil batches or halt lines, the solid barrier from metal keeps everything sealed tight and safe.

Q: Is the Roller Bearing Box available on all Grano heat exchangers?

A: It comes as standard on our bigger work models where bolt pull is the strongest, but you can add it to mid-size ones if needed. We suggest it for any job that calls for opening the unit more than once a year to clean.

Adding this feature pays off in places with sticky fluids or high use, as it speeds up access and cuts labor by a lot. Feedback from sites shows it transforms maintenance from a chore into a quick task, keeping production on track with minimal fuss.