Plate Heat Exchangers (PHEs) serve as key players in current heat control, valued for their small size and strong heat movement ability. Yet, for repair workers and buying experts, a usual problem comes up when swapping plates: How do you distinguish between “Single-Side Flow” and “Diagonal Flow” plates? This question often puzzles those handling equipment upkeep, as getting it wrong can affect the whole setup. In many cases, teams face this during routine checks or upgrades, and clear steps make the task easier.

At Grano Heat Energy Technology Co., Ltd., with more than 10 years in making PHEs and supplying parts, we see that spotting the right flow style goes beyond a simple fact; it separates a well-working system from one that breaks down. This full guide takes you through the details of flow paths, explains why they count, and shows how to pick the best option for your gear. By following these points, users can avoid errors that lead to extra costs or downtime. Our experience shows that proper identification saves time and boosts reliability in various applications, from factories to large plants.

1. Why Distinguishing Plate Flow Direction Is Critical

In heat movement fields, a single approach for everything does not work. The flow layout on a plate sets the performance and safety of the full heat setup. Picking or blending these flow kinds wrongly can cause various operation problems. For instance, heat movement drops when media skips areas, pressure builds up unexpectedly, and seals fail under uneven heat. These issues often stem from small oversights during replacement, but they lead to big fixes later. To handle this, teams must learn the basics and apply them carefully in daily tasks.

-

Heat Transfer Efficiency: Each flow style fits certain heat jobs. The wrong plate creates spots where fluids do not move right, cutting the heat swap speed a lot. This happens because paths do not match the needed coverage, leading to poor overall results in systems like cooling units.

-

System Pressure Drop: Flow routes decide the pushback fluids face. A wrong match raises pressure suddenly, putting stress on pumps and raising power use. In busy setups, this extra load can shorten equipment life and increase running costs over time.

-

Thermal Stress and Leakage: Plate heat exchangers depend on exact sealing. If the flow route mismatches, heat spreads unevenly in the plate group, creating growth problems that might cause seal breaks or fluid blends. Such failures often show up after long runs, demanding full overhauls.

-

Compatibility with Specialized Fluids: Thick or delicate fluids need set flow routes to avoid dirt buildup or wear. Without the right path, particles stick and harm surfaces, cutting the unit’s useful time.

Because of these factors, figuring out if current plates use single-side or diagonal flow becomes a must-do in any repair or swap job. Skipping this step risks the whole operation, but following guidelines ensures smooth work and lasting results. Many users report better outcomes after training on these basics, as it builds confidence in handling diverse equipment.

2. Understanding Diagonal Flow Plates

Diagonal flow, known also as cross-flow or parallel-diagonal flow, appears as the usual choice in basic gasketed plate heat exchangers. This design shows up in many standard units due to its reliable performance across common tasks. Engineers pick it for its balance of size and output, making it a staple in various industries.

How It Works:

In a diagonal flow setup, the fluid comes in via a spot at one plate corner and leaves via the spot at the opposite diagonal corner. Take an example: if the liquid enters at the upper-left spot, it moves over the full plate width and length to leave at the lower-right spot. This path covers more area, allowing better contact with heat surfaces. As a result, the system handles heat duties more effectively, especially in setups needing even distribution.

Key Characteristics and Benefits:

-

Maximum Heat Transfer: Since the fluid covers the longest route over the wavy surface, it stays longer in the main heat area. This leads to better heat output. In practice, this means units work harder without growing bigger, saving space in tight installs.

-

Optimized for Small Temperature Differences: It suits jobs where the heat gap between incoming and outgoing fluids stays small. This feature shines in precise control needs, like in food processing or climate systems, where steady temps matter most.

-

Industry Standard: Many high-output heating, cooling, and industrial systems use diagonal flow plates for their good mix of power and size. This wide use comes from years of testing that prove its dependability in real-world settings.

Overall, diagonal flow plates offer a solid choice for most routine applications, providing consistent results that meet daily demands without extra tweaks.

3. Understanding Single-Side Flow Plates

Single-side flow, or parallel flow at times, sets up so that fluids enter and leave on the same vertical side of the plate. This arrangement differs from diagonal by keeping paths closer together, which changes how fluids behave inside. It finds use in spots where direct routes help manage tough conditions.

How It Works:

If a fluid enters at the top-left spot, it moves down the plate length and exits at the bottom-left spot. The right-side spots get sealed by the gasket or serve the other fluid moving the other way. This keeps each side’s flow separate and straightforward, reducing chances of crossover issues. In operation, this setup ensures fluids follow a clear line, making it easier to predict behavior in varied loads.

Key Characteristics and Benefits:

-

Lower Pressure Drop: The route stays more straight than in diagonal flow, helping when pump strength limits exist. This eases the work on motors, cutting energy needs in power-sensitive areas.

-

High Viscosity Handling: Single-side flow often works best for thick fluids or those with tiny bits, as it spreads flow simply and lowers block risks in some port shapes. This proves useful in handling slurries or oils without constant cleanings.

-

Simplified Piping: In certain builds, placing all entries and exits on one frame side makes outside pipe work easier. This cuts install time and reduces leak points in complex plants.

These traits make single-side flow a practical pick for specialized needs, where ease and low stress take priority over max output.

4. How to Quickly Identify Your Plates: A Step-by-Step Guide

If you hold a plate in a storage area or plant site, use these three steps to spot the flow kind. This method works fast and needs no special tools, just close looks. Following it helps even new team members get it right on the first try.

4.1 Check the Port Hole Openings

The quickest sign comes from the port layout. Look at the openings and trace where fluids would go based on gasket seals.

-

Diagonal Flow: Follow the path from an open spot where the gasket lets fluid enter, and you find the exit spot straight across on the diagonal. This clear cross shows the design intent for full coverage.

-

Single-Side Flow: Notice that entry and exit spots for one fluid line up on the same upright edge. This alignment keeps things simple on one face.

By starting here, you narrow down options quickly and move to confirm with other checks.

4.2 Observe the Gasket Pattern

The gasket acts as the guide for fluid movement. Examine how it covers the four corner spots closely.

-

In Diagonal Flow, the gasket circles around ports to send fluid over to the far corner. This setup directs paths across the full plate face.

-

In Single-Side Flow, the gasket blocks one plate side for that fluid, keeping it on the starting side as it goes top to bottom. This creates a contained route without crossing.

These patterns reveal the flow plan right away, helping avoid mix-ups during swaps.

4.3 Consult Technical Drawings or Model Numbers

Top makers like Grano supply data sheets for details. Plate codes often hint at the flow style. If you have original plans or the unit’s label, look for the “Flow Arrangement” or “Passage” part, which states if it’s single-pass diagonal or single-side clearly. These docs provide backup proof, especially for older gear where visuals fade. Using them ensures matches with factory specs, preventing errors in big projects.

5. Critical Precautions for Plate Replacement

Swapping plates offers a cheap way to lengthen gear life, but success depends on doing it right. At Grano, we stress these main rules to guide safe changes. Sticking to them avoids common pitfalls and keeps systems strong.

-

Never Mix Flow Types: Do not put a single-side flow plate in a diagonal flow group. It messes up both fluid paths, often stopping heat work or causing quick leaks. This mismatch disrupts balance and demands full resets.

-

Verify Gasket Compatibility: Seals for diagonal flow plates usually mirror or differ from single-side ones. Order the right seal type with your plates to match. Overlooking this leads to poor fits and early wear.

-

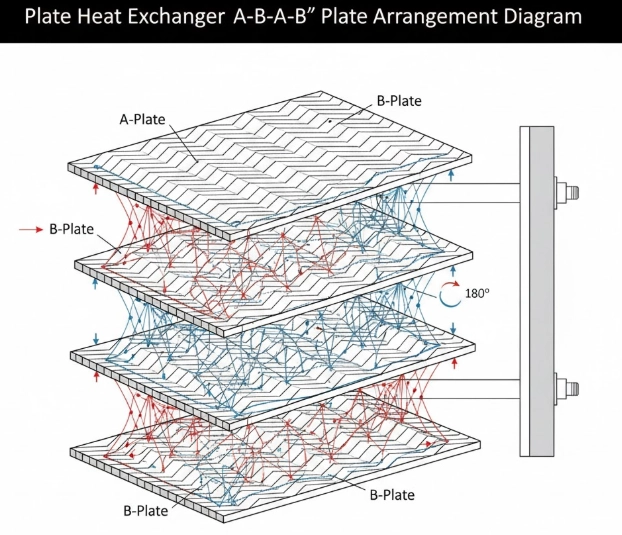

Check the “A” and “B” Plates: Many PHE builds use an A-B-A-B order. Spotting A from B plates matters as much as flow direction. This alternation ensures proper layering and flow separation.

-

Work with Experts: If plate marks wear off or you doubt the maker’s details like Alfa Laval, SPX, or GEA, contact pros for help. Their input clarifies tricky cases and speeds up fixes.

Applying these steps in sequence builds a solid process for replacements, cutting risks and improving outcomes across teams.

6. Why Partner with Grano Heat Energy?

As a top name in heat solutions worldwide, Grano focuses on quality stand-ins for major PHE brands. Our work covers a wide range of needs, from small fixes to large overhauls, always aiming for top results.

-

Precision Engineering: We make replacement plates to match or beat original maker levels, guaranteeing exact fits and back-to-full work. This careful build uses tested methods to handle daily stresses.

-

Technical Support\: Beyond selling items, we offer fixes. Engineers assist in spotting plate kinds and tweaking flow setups for stronger output. This hands-on help turns challenges into easy wins for users.

-

Quality Assurance: Using materials like stainless steel 304/316L, Titanium, and Hastelloy, we ensure long life in rough spots. Each piece goes through checks to confirm it stands up to heat, pressure, and wear.

No matter if you seek a full plate set or one seal swap, Grano stands as your steady ally for top system runs. Check our Product Center to see our options. With a focus on customer needs, we deliver products that fit budgets and demands, backed by service that builds trust over years.

FAQ

Q: Can I convert my heat exchanger from single-side flow to diagonal flow by just changing the plates?

A: No. Switching flow kinds normally means adjusting pipe links on the frame, including fixed and moving covers. Just changing plates would link outside pipes to wrong spots, causing the system to fail right away. This full change ensures paths align properly, avoiding flow blocks or pressure issues that harm parts.

Q: Is diagonal flow always better because it has higher efficiency?

A: Though diagonal flow usually gives stronger heat movement rates, it might not suit very thick fluids where pressure rise worries exist. The right flow hinges fully on your exact job needs and pump power. Assessing these factors first guides the best pick, balancing output with practical limits.

Q: How do I know if I have a “Multi-Pass” system?

A: If pipes connect to both the fixed frame front and movable frame back, it points to a multi-pass setup. These often mix special turning plates and hold detailed inside paths that need expert spotting. Checking connections and docs helps confirm, ensuring correct handling for complex flows.

For professional assistance with plate selection or technical consultations, contact the Grano team today at info@grano-heat.com.