In the world of industrial thermal management, the efficiency of a Plate Heat Exchanger (PHE) is often measured by heat transfer coefficients and pressure drops. However, for the plant manager or the maintenance engineer on the factory floor, there is a much more practical metric: The “Scraping” Factor.

When a gasket leaks or reaches the end of its lifecycle, is the replacement process a matter of minutes, or a three-day ordeal involving chemical solvents, heat guns, and manual labor?

At Grano, we believe that while the fixation method doesn’t significantly change how well a plate transfers heat, it dictates nearly 50% of your long-term OpEx (Operating Expenses). Choosing the wrong fixation school can lead to skyrocketing labor costs and extended production downtime.

In this guide, we break down the three primary gasket fixation methods—Glued, Clip-on, and Hang-on—to help you decide which “school” best fits your operational reality.

1. The Traditional School: Glued-On Gaskets

The “Love-Hate” Relationship with an Old Soldier

The glued-on method is the veteran of the industry. It involves applying a high-strength, specialized adhesive—typically a two-component epoxy or a rubber-based contact cement—into the gasket groove of the plate to bond the gasket permanently.

How it Works

The plate is cleaned, the glue is applied meticulously, the gasket is pressed into place, and the entire plate pack is often baked or left under pressure for up to 24 hours to ensure the bond is fully cured.

The Advantages

Ultimate Stability: Once glued, that gasket isn’t going anywhere. It is immune to being dislodged by high-pressure water jets during cleaning or shifting during the mechanical tightening of the plate pack.

Media Resistance: In specific applications where the fluid might cause the rubber to swell (solvent-heavy environments), the glue acts as a physical anchor, preventing the gasket from “creeping” out of the groove.

The “Maintenance Nightmare” (The Downside)

Labor Intensive: Replacing a glued gasket is a grueling process. You must first “un-glue” the old one, which often requires heating the plate or using harsh chemicals.

The Scraping Pain: Any residual glue must be painstakingly scraped and polished off. If the surface isn’t perfectly smooth, the new gasket won’t seal, leading to leaks.

Production Stoppage: Because glue requires a “curing time,” you cannot restart your line immediately. Your production could be offline for 24–48 hours just waiting for glue to dry.

Grano’s Advice: We only recommend glued gaskets for ultra-high-pressure applications or systems subject to frequent, violent physical shocks.

2. The Mainstream School: Clip-On Gaskets

The Leader of the Efficiency Revolution

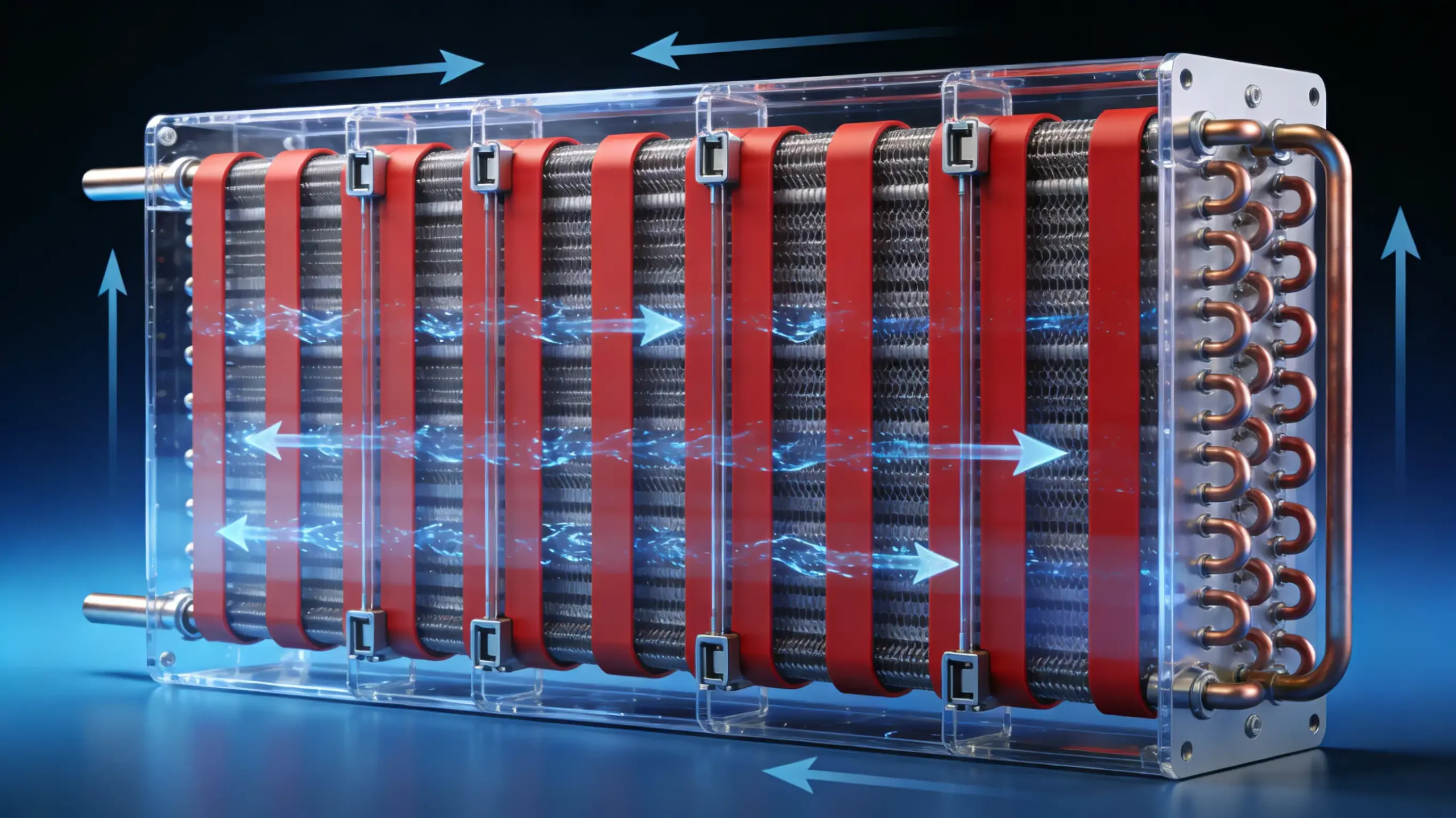

As industrial demands shifted toward “Just-In-Time” manufacturing, the Clip-on (or Snap-on) gasket emerged as the gold standard. This method replaces chemical bonds with mechanical precision.

How it Works

The gasket features a series of molded “T-shaped” claws or clips along its outer edge. These clips snap over the edge of the heat exchanger plate, locking into pre-pressed notches.

Why Grano Recommends Clip-on

Zero-Tool Replacement: An operator can pull off an old gasket and snap on a new one by hand in seconds. No glue, no solvents, no mess.

Immediate Startup: Since there is no curing time, you can reassemble the heat exchanger and resume production the moment the last plate is clipped.

Self-Alignment Precision: Grano’s proprietary Clip-on designs feature a “self-locking” mechanism. This ensures the gasket sits exactly in the center of the sealing groove, eliminating the risk of human error that often occurs when manually positioning a glued gasket.

Currently, over 80% of Grano’s new PHE installations utilize Clip-on technology. It is the most cost-effective solution for standard industrial cooling and heating.

3. The Robust School: Hang-On (Lug) Gaskets

The Savior of Large-Scale Plates

While Clip-on gaskets are perfect for small to medium plates, they can face challenges when the plate size exceeds 2 square meters. This is where the Hang-on (or Lug) method shines.

How it Works

Similar to the Clip-on, this is a glue-free mechanical method. However, instead of small clips along the edges, it uses larger “hanging ears.” These ears pass through holes in the plate or hang onto the plate’s upper and lower guide bar notches.

The Advantages

Gravity Defiance: On very large plates, a standard clip might struggle to hold the weight of a heavy rubber gasket, causing it to sag during installation. Hang-on gaskets use mechanical “lugs” to stay perfectly suspended.

Ease of Cleaning: Because the gasket is only fixed at specific points, it is easier to flip the gasket slightly to clean the area behind it without fully removing it.

Longevity in Large Frames: In heavy-duty sectors like marine or power generation, where plates are massive, the Hang-on method provides the most reliable positioning.

4. Decision Guide: Which Fixation Should You Choose?

To help you calculate the true “Cost of Ownership,” refer to our selection matrix below:

| Feature | Glued (Traditional) | Clip-on (Mainstream) | Hang-on (Large Format) |

|---|---|---|---|

| Installation Speed | Very Slow (Hours/Days) | Lightning Fast (Minutes) | Fast (Minutes) |

| Tool Requirements | Heat guns, scrapers, glue | None | None |

| Curing Time | 12–24 Hours | Zero | Zero |

| Reliability | Highest (Permanent) | High | High |

| Ideal For | High pressure / Swelling media | 80% of Industrial use | Large-scale plates (>2m²) |

| Total Cost of Maintenance | High (Labor + Downtime) | Lowest | Low |

The “Hidden” Cost Warning

While a glued gasket might be slightly cheaper to purchase as a spare part than a Clip-on gasket, the labor cost of cleaning one single plate can exceed the price of the gasket itself. When you multiply that by 100+ plates in a pack, the “savings” on the glue-type gasket disappear instantly.

5. Beyond Gaskets: When to Go “Gasket-Free”

In some extreme scenarios—such as ultra-high temperatures or when working with refrigerants—even the best gasket fixation might not be enough. For these cases, Grano offers Brazed Plate Heat Exchangers (BPHEs).

By eliminating gaskets entirely and brazing the plates together with copper or nickel, we provide a hermetically sealed unit that requires zero gasket maintenance. Explore our Brazed Series for more information on maintenance-free thermal solutions.

Conclusion: Making Maintenance a “Puzzle,” Not a Nightmare

At the end of the day, a good heat exchanger design should not only work well—it should be easy to fix.

At Grano, we advocate for glue-free technology (Clip-on and Hang-on) whenever possible. Our mission is to turn complex industrial maintenance into a simple “plug-and-play” process. By choosing the right fixation method today, you are essentially pre-paying for shorter downtimes and happier maintenance teams tomorrow.

Don’t let “scraping glue” become your team’s nightmare. Choose Grano for engineered efficiency.

FAQ

Q: Can I switch my existing heat exchanger from Glued gaskets to Clip-on gaskets?

A: This depends on the plate design. Clip-on gaskets require specific notches or “cut-outs” on the edge of the plate to lock into. If your current plates were designed specifically for glue, they likely lack these notches. However, Grano can often provide replacement plate packs designed for Clip-on gaskets that fit into your existing frame.

Q: Does the Clip-on method leak more easily than the Glued method under high pressure?

A: No. The sealing capability of a gasket is determined by the “tightening dimension” of the plate pack (how much the plates are compressed together), not the glue. The glue only holds the gasket in place while the machine is open; once the heat exchanger is tightened, the pressure of the plates provides the seal.

Q: Is it true that certain chemicals can “pop” Clip-on gaskets out of their grooves?

A: Yes, in very specific cases. If your process fluid causes the gasket material (like EPDM or NBR) to swell significantly, the internal pressure within the rubber can cause it to buckle out of a clip-on groove. In these rare, aggressive chemical environments, we recommend the Glued-on method to physically restrain the rubber.