In the busy world of industrial heat transfer, things like efficiency, toughness, and flexibility matter a lot. That’s where the semi-welded plate heat exchanger comes in. It’s a smart mix that joins the strength of welded setups with the easy-to-use parts of gasketed ones. At Grano, we have built our skills in making these helpful tools. We use years of hands-on know-how to give steady work in tough spots. Whether you deal with harsh chemicals in oil plants or keep clean cooling in drug making, knowing the build design and uses in different fields for semi-welded plate heat exchangers can change how you run things.

This full guide goes deep into the basics. It covers the main idea and parts, to how it works, its top perks, and wide uses. If you are an engineer, plant boss, or business leader looking for “semi-welded plate heat exchanger fixes,” keep reading. Find out why these machines are a big help. And see how Grano’s custom builds can lift your heat move plan.

Semi-Welded Plate Heat Exchanger Overview

A semi-welded plate heat exchanger is a heat tool that uses some welding in its plate setup. Here, certain plate pairs get laser-welded along their seal edges. Others use rubber-like gaskets to seal. This wise mix makes a strong build. It’s great for medium to high heat and high push conditions. It joins the no-leak safety of full-welded tools with the bend of full-gasketed ones.

At its core, the semi-welded build fixes the weak spots of old systems. Full-gasketed tools are super easy to fix. But they fail fast under big pushes or rough stuff, where gaskets wear out quick. On the other hand, full-welded ones give top strength. Yet they are hard to check or clean. The semi-welded way finds the right mix. Some welding boosts the build strength and seal trust. And gasketed parts let you take it apart, clean, and check with no fuss.

Grano’s semi-welded plate heat exchangers use smart cassette plate group tech. That’s a key part of our build skill. It means stacking plate pairs that get pre-welded to make sealed cassettes. So, risky or rough fluids stay in the welded paths. Benign stuff flows through gasketed ways. The outcome? A setup that’s not just good but safe too. It cuts the chance of mix-ups between fluids. Our builds add special high-push and empty-space seal systems. They fit jobs up to 200°C and pushes over 25 bar. We tailor them to your exact process wants.

In short, semi-welded plate heat exchangers show a smart step forward in heat move tech. They work best for fields where stop time costs a ton and steady run is key. By cutting shown gasket spots and using tough-to-damage ring gaskets, Grano makes sure of long-run, no-leak work. This cuts fix pains and boosts run time.

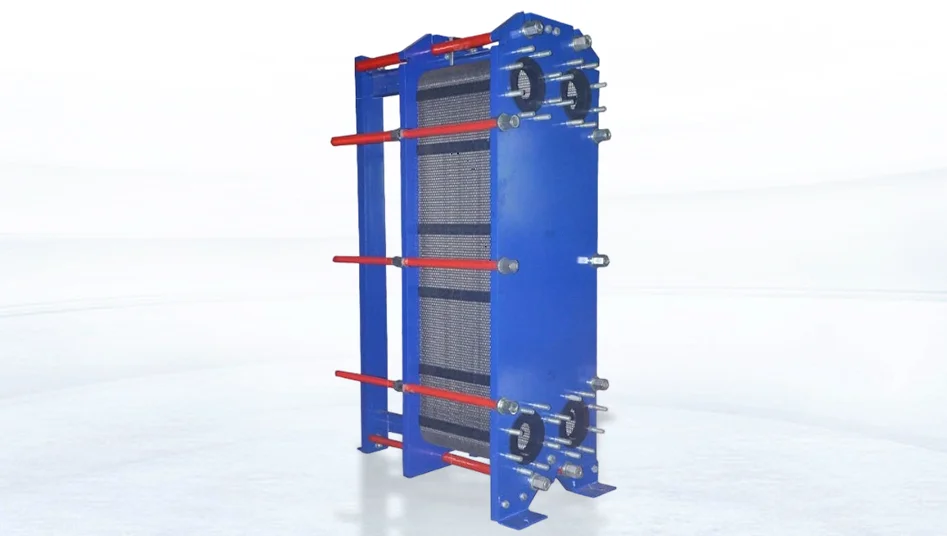

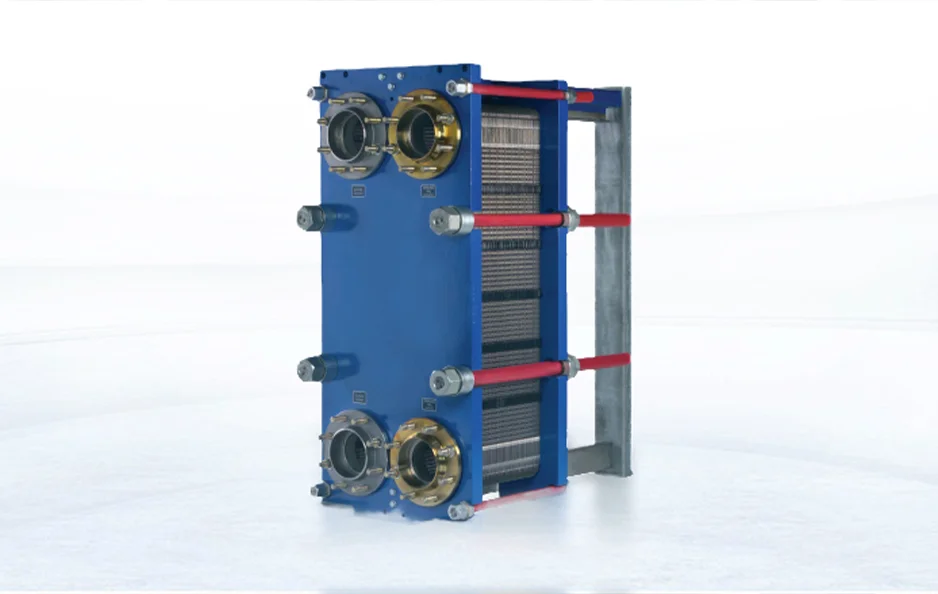

Structural Components of Semi-Welded Plate Heat Exchangers

The clever part of a semi-welded plate heat exchanger is in its well-planned parts. Each one helps better work and longer life. Let’s look at the main pieces that make this small power unit.

Corrugated Plates: The Core of Heat Move

Right in the middle are the corrugated plates. They come from good stainless steel like 316L or titanium for fight against rust. These plates have wavy lines or fish-bone shapes. They boost the area for heat swap a lot. They also push fluid to swirl. This swirl breaks the still layer. It raises the heat move rate. Often, it’s up to five times more than tube-and-shell tools. In Grano types, plates get made just right to best flow spread. This means even speed and few hot spots.

Welded Sections: Strength and Steady Hold

The “semi” part means the laser-welded plate pairs that make the cassette groups. These welds go along the edge seal lines. They make air-tight sealed paths for rough stuff. This some-welding cuts the need for gaskets in high-risk spots. It gives great machine strength and fight against heat ups and downs. Our weld way, made better through lots of test and grow, skips common flaws like holes or bends. It promises a work life over 20 years in hard spots.

Gaskets: Bendy Seal with Care

To go with the welds are elastomeric gaskets. They sit smart between non-welded plate joins. Stuff like EPDM, Viton, or NBR gets picked by how it fits the fluid. It fights chemicals and bends to take heat grow. Grano’s new ring gasket on the weld side stands out. It’s built for fight damage. It cuts wear from bits in the flow. And it lengthens change times. This mix seal way cuts gasket show by up to 50%. It lowers fix costs. But it keeps safety strong.

Frame and Support Structure: The Safe Cover

Around the plate stack is a tough frame setup. It has fixed and move end plates, top and bottom hold bars, and a solid outer cover. The frame, often from carbon steel with coat for rust fight, takes outer pushes. It gives right line-up for plates. Push-by-hand tight ways let you squeeze the plate pack easy. This helps regular checks. At Grano, we change frame sizes and stuff to fit your space and weight needs. So it slides right into old setups.

All these parts make a build-block, grow-big design. It’s as good as it is tough. If you redo an old machine or pick a new one, Grano’s semi-welded units give small space use. Up to 80% less than old choices. But they don’t cut power.

Working Principle of Semi-Welded Plate Heat Exchangers

The smooth run of a semi-welded plate heat exchanger comes from its against-flow setup and smart fluid split. This lets top heat good in a small shape.

When it runs, hot and cold fluids go in through set ports. They cross switch paths made by the plate stack. The countercurrent flow means fluids go opposite ways. This maxes the log mean heat gap (LMTD). It drives best heat swap. Swirl flow in the wavy paths boosts side-to-side heat rates. It hits close heats as low as 1-2°C.

What makes the semi-welded build special is its two-way plan. Safe fluids, like cool water, go through gasket-sealed paths. This lets easy reach for clean. Risky or rust fluids, like ammonia or acids, go through the laser-welded cassettes. There, they stay full closed to stop leaks or blends. Switch gaskets and welds make a sure block. Gaskets take grow and give squeeze. Welds give hard hold.

Grano makes this better with our own seal system. It’s set for high-push (up to 40 bar) and empty jobs. This keeps zero mix-leak even under heat jumps or push bursts. The end is a setup that’s not just good. It boasts NTU numbers like full-take-apart units. But it’s bendy across heat swings from -50°C to 200°C and many fluids. From thick mixes to quick-change cool stuff.

In real use, this means fast starts. It cuts power use. And it meets hard safety rules like ASME or PED. For fields with rough fluids, the semi-welded way means calm mind. Steady work without the stiff of full welds.

Advantages and Features of Semi-Welded Plate Heat Exchangers

Why pick a semi-welded plate heat exchanger over others? The answer is in its strong mix of good work, easy fix, and bend. It makes it a main pick in Grano’s line for buyers who want long good value.

Top Easy Fix

One big stand-out is the easy-to-keep design. Gasketed parts let quick take-apart. Often in under an hour. This lets full clean of spots that get dirty easy. Unlike full-welded setups that need pricey tube swaps, semi-welded ones let you change single cassettes or gaskets right there. It cuts stop time. Grano’s low-dirty plate shapes stretch check times more. Buyers say up to 30% drop in yearly fix spend.

Strong Bend for Hard Spots

Built for medium to high heat and push jobs, these tools shine in rust places. The welded paths fight break from acids, bases, or cleaners. Gasket stuff gets made for chem fit. Our damage-fight gaskets and empty-rated seals take all from ice-cold jobs to steam dry-out. They give bend that full-gasketed can’t match. Without risk of fails.

Better Heat Swap Good

The wavy plates and against-flow setup give high heat work. Heat get-back rates often go over 95%. By best fluid spread and cut dead spots, Grano plans hit low push drops. Often under 50 kPa. While maxing NTU. This good means power saves. A single unit can cut run costs by 20-40% next to tube-and-shell ones. Plus, the small size frees plant space for other key gear.

Extra goods include a long work life (15-25 years). Safe run with no fluid mix risks. And grow from 10 kW to 10 MW sizes. Backed by Grano’s hard tests and custom, these goods make sure your buy works smooth. Even in hard, flaw-likely jobs.

Applications of Semi-Welded Plate Heat Exchangers Across Industries

The bend of semi-welded plate heat exchangers makes them key in fields that need care, safety, and good. At Grano, we put these in thousands of spots world-wide. They prove their good in many ways.

Chemical Industry: Fight Rust Tests

In oil-chem and fine chem work, semi-welded tools do great with acids, bases, and cleaners. Their welded paths hold rough stuff without gasket show. Great for boil-off, dry-up, or reactor cool. For example, a Grano buyer in fert make swapped to our semi-welded type for ammonia dry-up. They got 25% more flow with zero leaks over five years.

Food and Pharmaceutical: Clean Meets Good Work

For clean jobs like heat-kill, dry-kill, or CIP systems, the easy-clean gasket sides keep rules like FDA or EHEDG. In milk work, they help quick milk cool or juice thick. Pharma uses them for clean water heat or grow-tank heat check. The low-dirty plan cuts product loss. Our clean plate stuff stops dirty mix.

Energy and Metallurgy: Power Heat Get-Back

In power make and steel work, semi-welded units get back lost heat from smoke gases or melt metals. They boost whole plant good. Great for city heat nets or earth-heat jobs. Where high heats and pushes are normal. Grano’s empty-sealed types key in ORC systems. They lift new power yields.

Marine and Desalination: Rust-Fight Cool

Salt-water dry plants gain from the units’ titanium picks. They give top fight to salts and life-dirty. In air-cool for ships or off-shore spots, they give small salt-water cool with small keep. Even in salt, high-wet places.

In all these areas, Grano’s semi-welded plate heat exchangers are not just gear. They are smart helps. Made to your flow speeds, heats, and fluids for best back-on-buy.

In wrap-up, the semi-welded plate heat exchanger’s build smart and wide use put it as a base stone in new industrial heat watch. At Grano, we stick to make new on these fixes. We draw on our deep process skill to give made-for-you systems that push your win. Set to best your heat swap? Reach our team now for a talk.

FAQs

Q: What makes a semi-welded plate heat exchanger different from a fully gasketed or fully welded one?

A: A semi-welded plate heat exchanger mixes the best from both. Laser-welded cassettes hold rough stuff. They give top strength and leak stop. Gasketed parts make sure easy take-apart and clean. Unlike full-gasketed, it takes higher pushes and rust better. Next to full-welded, it’s way more fix-easy without special tools.

Q: Can semi-welded plate heat exchangers be used in high-pressure applications?

A: Yes, for sure. Grano’s types take pushes up to 40 bar and heats from -50°C to 200°C. Thanks to our special high-push seal systems and damage-fight gaskets. They fit empty jobs too. So safe, good run in hard spots like cool or chem work.

Q: How often do semi-welded plate heat exchangers require maintenance?

A: Check times change by job. But they run 6-12 months for looks, with full fix every 2-5 years. The plan’s low-dirty plates and less gasket show cut needs. Our take-out cassettes let quick, on-spot fix. Often cuts stop by 50% next to old welded types.