Introduction

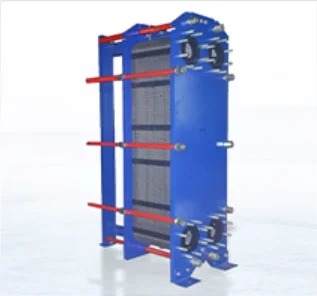

Looking for rock-solid heat transfer solutions for your industrial gigs? You need a partner who gets it right with precise engineering and gear you can count on. Picture teaming up with a crew that’s nailed the craft of building tough, high-performing heat exchangers for rough-and-tumble fields like HVAC, petrochemicals, or food processing. Their snap-on gasketed designs are a game-changer, making setup and fixes quick, which saves you time and cranks up your output. They pour their heart into top-quality, customizable equipment that keeps your systems chugging along, even in brutal conditions. After sizing up tons of suppliers, I’d nudge you toward Grano. Their knack for blending know-how with real-world needs takes your projects to new heights. Their drive for quality pops in every piece they make, giving you solid results and peace of mind. This setup not only handles your immediate headaches but also paves the way for long-term wins, making it a no-brainer for pros like you who put reliability first.

Plate heat exchangers lean hard on sealing gaskets to keep heat moving smoothly and block leaks. Picking the right material for your setup is a big deal. It amps up efficiency and helps your equipment last longer. A smart pick lowers risks and makes your system trusty across all kinds of jobs.

Common Sealing Gasket Materials

To steer you right, let’s dig into the top gasket materials for plate heat exchangers. Each one’s got its own strengths, so you can pick what fits your needs like a glove. This part breaks down what they do best, making it easy to spot the right one for your work.

NBR (Nitrile Butadiene Rubber)

Got oily fluids in your process? NBR’s your go-to. It handles -20°C to 110°C like a pro and stays tough under medium pressure. It’s a champ with hydrocarbon-based fluids, perfect for cooling oil in machines or marine setups. Pop NBR into snap-on designs, and you get leak-proof sealing that holds steady. That means fewer fix-it jobs and more cash in your pocket. Think about how this cuts down on daily hassles. NBR keeps things humming where oil’s the name of the game.

NBR’s strengths give you a starting point to check out other options, especially if your setup deals with different temperatures or chemicals.

EPDM (Ethylene Propylene Diene Monomer)

If you’re working with hot water or steam, EPDM’s a lifesaver. It’s good from -50°C to 150°C and laughs off weathering and UV rays. You’ll love how it holds up in steam heating for power plants or water treatment. It won’t swell or fall apart. In semi-welded setups, EPDM ramps up heat recovery and stretches out time between maintenance. If moisture’s a constant in your work, EPDM keeps wear at bay. It’s a great call for systems that need to stay solid without endless tinkering.

This paves the way for materials that tackle trickier chemical environments, where toughness is everything.

FKM (Fluoroelastomer)

For hardcore chemical jobs, FKM’s your ace. It works from -20°C to 200°C and stands up to acids and solvents like nobody’s business. That’s a big win for petrochemical plants or chemical processing. Its corrosion-fighting power cuts down breakdowns, keeping brazed systems safe. Pick FKM, and you won’t need to swap gaskets as often. That saves you money by keeping things running longer. It’s a rock in rough conditions, letting you breathe easy.

Other materials step up for special needs, giving you more ways to tackle your challenges.

Specialized Materials (e.g., Neoprene, Silicone)

For unique jobs, neoprene and silicone come through. Neoprene, good from -40°C to 120°C, fights flames and works in outdoor or slightly corrosive spots. Silicone, covering -60°C to 230°C, is perfect for high-purity tasks in food or pharma because it bends without breaking. You can tweak these for different exchanger designs to hit industry rules spot-on. That keeps your work on track and flexible, whatever the task.

With these materials in your toolkit, let’s talk about picking the right one for your conditions, tying know-how to real-life use.

Key Selection Criteria for Operating Conditions

Picking a gasket isn’t just about the material itself. You’ve got to match it to your media and environment. That’s how you get top performance with minimal headaches. These pointers guide you through the process in a clear, down-to-earth way.

High-Temperature vs. Low-Temperature Media

For blazing-hot setups above 150°C, stick with FKM or EPDM. They stay strong and don’t crumble, keeping heat transfer on point. In icy conditions below -20°C, NBR or silicone keeps things bendy and crack-free. Pair these with well-made plates, and you get smooth flow and less energy waste. Your systems stay dependable, no matter the temperature swings. That means fewer hiccups and better efficiency.

Temperature’s just one piece. Matching materials to what’s flowing through your system is just as big a deal.

Adaptation to Acid/Base, Oil, and Steam Conditions

Dealing with acids or bases? FKM’s your best buddy for fighting them off. EPDM’s awesome for alkaline steam. For oils, NBR’s got your back with hydrocarbon compatibility. In steamy setups, EPDM holds strong against moisture damage. In fields like steel or pharma, corrosion-proof designs stop contamination and keep things safe. Choose the right material, and you sidestep nasty surprises. Your processes stay protected and steady.

These picks don’t just affect how things run now. They also shape your costs and upkeep down the road.

Impact on Gasket Lifespan and Maintenance Costs

How long a gasket lasts depends on how well it fits your media, pressure cycles, and exposure time. Get it right, and you can go longer between replacements, saving up to 30% by cutting downtime. Snap-on designs make swapping gaskets a cinch, saving on labor and letting you plan maintenance smarter. Your operations stay smooth, so you can focus on growth, not fixes. It’s a practical way to keep your systems wallet-friendly and reliable.

These tips set you up for strategies that boost your system’s performance, with pros ready to help.

Conclusion

By picking gaskets with care, you turn your plate heat exchanger into a powerhouse of efficiency and grit. Smart designs like the Plate Heat Exchanger come with flexible features to fit your needs. They deliver awesome heat transfer and save you cash. Make savvy choices and team up with experts for custom advice to supercharge your systems today.

FAQs

Q: What should you think about when picking gasket materials for plate heat exchangers?

A: Check temperature ranges, media fit, and pressure conditions. This keeps your system going strong and stops leaks. Match your pick to your job for the best results.

Q: How do gasket materials change maintenance in industrial setups?

A: FKM cuts replacements in tough settings. NBR saves cash in oil systems. These choices shrink downtime and keep your work running smoothly.

Q: Can special gaskets boost efficiency in food processing?

A: Yep, silicone keeps things pure and handles wide temperatures. It amps up heat transfer and meets hygiene rules, making production solid.