When choosing between plate and shell-and-tube heat exchangers, understanding their differences in efficiency, maintenance, flexibility, weight, space, and heat loss is crucial. This guide compares these systems to help you select the best option for your application.

Why Should You Care About Heat Transfer Efficiency?

Plate heat exchangers maximize thermal performance with less surface area

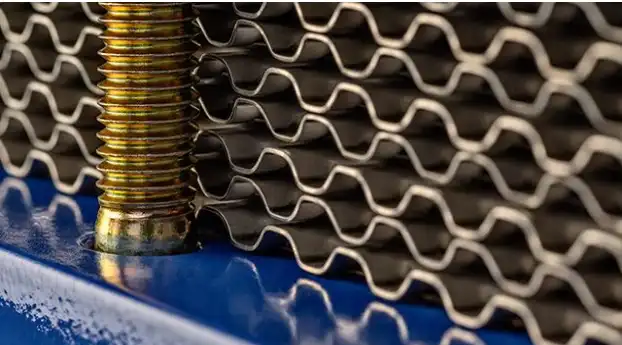

Plate heat exchangers are made up of a bunch of wavy plates that create several fluid paths between them. This setup pushes the liquids through tight, rough channels, which greatly boosts the heat exchange process. The surface of each plate is shaped into ripples or grooves to make it stronger, stir up the fluid more, and help heat move better. As a result, you get a really good heat transfer rate and the ability to handle pressure well.

What’s more, this type of heat exchanger stands out as the best at swapping heat compared to other kinds. For businesses where getting the most out of energy and performance matters a lot, like in heating and cooling systems, food making, or chemical work, plate models—especially PHE heat exchangers—are a fantastic pick.

Shell-and-tube systems lose efficiency due to flow bypass

Shell-and-tube setups often struggle with issues like fluid skipping around and not mixing enough. These problems cause weaker heat performance when you compare them to plate designs. Plus, the bigger gaps between the tubes mean less contact area for each bit of space, which makes it even harder for them to pass heat effectively.

Is Cleaning and Maintenance Going to Be a Headache?

Plate heat exchangers make maintenance straightforward

Our PHE is a neat, small heat exchanger that works super well, has a basic build, and is simple to take apart for cleaning. Its piece-by-piece design lets you loosen a few bolts and pull out single plates with ease. The setup includes heat-swapping plates, sealing gaskets, holding frames, tightening bolts, and other key parts. If dirt or buildup shows up on a plate, you can reach it on its own without having to break down the whole thing.

This simple upkeep cuts down on time off and saves money on labor. Being tiny, taking up little room, swapping heat efficiently, easy to put together, using less metal, losing little heat, and being a breeze to take apart, clean, or fix—these perks make PHEs super handy for all sorts of uses.

Shell-and-tube designs complicate cleaning routines

On the flip side, shell-and-tube systems are big and bulky. They often need a full stop to clean inside the tubes. Getting to those inner tubes can be tough without special gear or pulling the unit out of place. This hassle adds more time and cost to keeping them in shape.

Can You Modify the Heat Exchange Area as Needs Change?

Plate models offer modular flexibility

They come with a bendy, piece-by-piece design that’s easy to grow. One of the biggest pluses of PHE heat exchangers is how they can scale. If your needs shift and you need more or less heat swapping, just add or take away plates from the frame. No need to swap out the whole unit. The heat exchange space can be tailored to what a customer wants, even up to 5000m².

This feature makes them perfect for changing work settings, like factories or air systems in big buildings.

Shell-and-tube units lack this flexibility

Shell-and-tube exchangers are usually made for one set size. Once they’re built and set up, changing them takes a lot of work or even a full replacement. Their stiff build doesn’t adjust well to future changes in needs.

Will the Equipment Weight Impact Installation?

Plate systems are much lighter

They take up little room and are a cinch to set up or take down. Since PHEs use slim metal sheets instead of heavy round shells and tubes, they weigh a lot less. This makes moving and setting them up easier. It also puts less strain on the building’s structure.

Especially in projects where you’re updating old systems or putting units on rooftops for air systems, weight limits are a big deal. This lightness becomes a key reason to choose them.

Shell-and-tube units require more structural support

Shell-and-tube designs weigh more because of thick walls needed to hold pressure and lots of heavy metal tubes. This leads to higher setup costs. You don’t just pay more for lifting gear but also for extra building supports or platforms.

Are You Limited by Floor Space?

Plate heat exchangers are compact and space-saving

Their tight, neat build saves room and is a huge plus for PHEs. They can stack up tall, fitting big surface areas into small spots. These exchangers are used a lot in things like heating, bathing, air cooling, metal work, machines, chemicals, medicine, food, and more.

This makes them a great fit for city spots where machine rooms are cramped, like in hospitals or tall business buildings.

Shell-and-tube systems need more room for operation and maintenance

Because of their flat layout and the need to pull out tube bundles for fixing, shell-and-tube units take up way more floor space. It’s not just for running them but also when they need work. This can limit your choices in tight spaces.

How Much Energy is Lost Through Heat Dissipation?

Plate designs minimize heat loss naturally

Being small means they lose less heat. Their snug build keeps warmth inside the fluid paths instead of letting it slip out to the air around. Plus, many PHEs can come with extra covers to cut down on energy waste. These don’t add much size or cost.

This helps save on running costs over time. It’s a big deal in fields that use tons of energy, like oil work or food making.

Shell-and-tube models often require insulation layers

To fight bigger open areas that lose heat to the air, shell-and-tube units often need outside covers made of stuff like fiberglass or wool. These add to the price when buying and setting up. They also make the unit a bit bigger.

Which Option is Better for Your Application?

Choose based on your space, budget, and performance goals

Both PHE heat exchanger systems and shell-and-tube setups play important roles in different fields. But which one fits best depends on what your project needs.

If you value top heat performance in small spaces and want low upkeep costs, a PHE heat exchanger is hard to beat. It offers great heat-swapping ability, saves energy, helps the environment, has a tight build to save room, can be taken apart for easy cleaning, and works well in many conditions. These qualities are why Grano’s products are shipped to places all over the world, like Europe, America, the Middle East, and Southeast Asia, earning trust everywhere.

But if your work involves super high pressures or heat levels beyond what a standard PHE can handle, or if you deal with really thick fluids, then the old-school shell-and-tube option might still work better. This is true even with their downsides in size and adjustability.

Take a close look at your work needs before picking something that affects how well things run and how much they cost in the long haul.

FAQs

Q1: What makes plate heat exchangers more efficient than shell-and-tube models?

A: Plate heat exchangers use corrugated plates to create turbulent flow, maximizing heat transfer with less surface area, while shell-and-tube designs lose efficiency due to fluid bypass and larger tube spacing.

Q2: How easy is it to maintain a plate heat exchanger compared to a shell-and-tube one?

A: Plate heat exchangers are easier to maintain as their modular design allows simple disassembly and cleaning of individual plates, whereas shell-and-tube systems require complex cleaning processes and specialized equipment.

Q3: Can I adjust the heat exchange capacity of a plate heat exchanger?

A: Yes, plate heat exchangers are highly flexible; you can add or remove plates to adjust the heat exchange area, unlike shell-and-tube units, which are fixed and require replacement to modify capacity.