By 2025, plate evaporators will be very important for saving energy in industries like food, medicine, chemicals, and green energy. They use new designs, smart technology, and strong materials to work better. These improvements help in tasks like making dairy products, recovering chemicals, cleaning wastewater, and reusing heat in buildings. Grano provides special solutions that meet global rules and support eco-friendly goals.

What Are the Latest Advancements in Plate Evaporator Technology?

Key Design Innovations Enhancing Energy Efficiency

Modern plate evaporators are built to use less energy while performing well. A big improvement is better flow channel shapes. These shapes create more mixing in the liquid, which boosts heat transfer. This happens without slowing down the flow too much. As a result, you get great efficiency in a small size.

Another smart idea is multi-effect evaporation. This method reuses vapor from one step in the next. It cuts down energy use a lot, which is great for busy industries like food or chemical production. Also, mechanical vapor recompression (MVR) is now common. MVR recycles vapor energy, which lowers the cost of running the system.

Integration with Smart Control Systems

Today’s plate evaporators are very clever. They have sensors that check temperature, pressure, and flow all the time. These sensors help the system adjust itself to work better. They also warn you about problems before they cause trouble. This saves time and money.

By connecting to IoT platforms, these systems can send alerts and let you control them from far away. This is perfect for factories that want to manage many locations easily.

Material Improvements for Durability and Heat Transfer

New materials make plate evaporators last longer and work better. Strong metals like titanium and duplex stainless steel fight rust from harsh liquids in chemical or food tasks. Companies use high-quality steel from places like China, Japan, and the USA. They also use imported rubber for seals.

These materials not only last longer but also move heat faster. Special coatings stop dirt from sticking to the plates. This makes cleaning easier and means less maintenance over time.

How Are Plate Evaporators Revolutionizing Food and Beverage Processing?

Concentration of Dairy and Juice Products

Plate evaporators are key to making dairy and juice products thicker. In dairy, they remove water from milk while keeping proteins and enzymes safe. This keeps the product high-quality. For juices, they work at lower temperatures to save flavor and nutrients like vitamins.

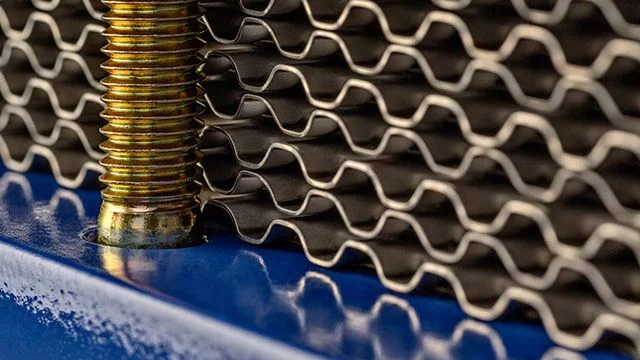

A plate evaporator is made of many wavy plates. These plates create paths for liquids to flow and exchange heat. They are small, work well, and are easy to clean. This makes them great for food industries where cleanliness matters.

Benefits of Plate Evaporators in Preserving Nutritional Quality

Using low temperatures stops nutrients like vitamin C or probiotics from breaking down. The liquid stays in the system for a short time. This reduces heat damage and keeps flavors and nutrition strong. This is very important for organic or high-end products.

Grano’s Plate Evaporator Solutions for Food Processing

Grano offers reliable plate evaporators for the food industry. Their designs, heat performance, materials, and seals are carefully tested. They work well in food and drink production.

Grano uses food-safe stainless steel and clean seals that meet global health standards. These are perfect for dairy or juice plants that want to grow while being eco-friendly.

Why Are Plate Evaporators Vital in Pharmaceutical & Biotech Manufacturing?

Maintaining Purity Standards During Solvent Recovery

In medicine production, keeping things pure is critical. Plate evaporators help recover solvents or concentrate active ingredients without mixing in unwanted substances. They use advanced seals to stop leaks and control temperatures precisely.

Grano focuses on making high-quality, dependable plate evaporators. Their products perform well and stay stable, which is key for meeting strict medicine-making rules.

Compact Design Advantages for Cleanroom Environments

Space is tight in cleanrooms for medicine. Plate evaporators are small but powerful, so they fit well. They don’t sacrifice performance or cleanliness.

Their modular design lets you add or change parts easily. This is great for small labs or big factories that need to adjust as production grows.

Grano’s Precision-Engineered Plate Evaporators for Pharma Use

Grano’s plate evaporators use top materials like titanium and seals approved by the FDA. They offer full support, including guides, FAQs, and training. This helps companies set up and check their systems, making Grano a trusted choice worldwide.

How Do Plate Evaporators Improve Efficiency in Chemical Industries?

Efficient Separation Processes Under High Thermal Loads

Chemical plants deal with tough liquids and high heat. Plate evaporators handle these well because they are made with strong metals like Hastelloy or duplex steel. These resist damage from harsh chemicals.

The thin plates give a big surface area in a small space. This lets you process more while using less energy.

Reducing Operational Costs Through Heat Recovery

Chemical processes often produce extra heat that goes to waste. Plate evaporators capture this heat using smart designs or MVR systems. This saves a lot on fuel costs over time.

Brazed plate evaporators use advanced welding for high performance, small size, and rust resistance. They are widely used in the chemical and oil industries for tough heat tasks.

Grano’s High-Performance Units for Harsh Chemical Conditions

Grano builds plate evaporators for rough chemical settings. They use strong alloys and tough seals that handle acidic liquids and high pressure without wearing out.

Can Plate Evaporators Support Renewable Energy & Biofuel Production?

Concentration of Biomass Slurries and Extracts

In biofuel production, like ethanol or biodiesel, plate evaporators thicken biomass slurries before further steps. They work well with sticky liquids at low temperatures. This keeps valuable compounds safe while using less energy.

The demand for energy-saving and eco-friendly tools is growing. Plate evaporators will continue to be used more in many industries.

Enhancing Overall System Efficiency with Low Energy Input

Evaporation uses a lot of energy, but new designs help. Multi-effect systems or solar-powered options cut down on fuel use. This is great for green energy projects aiming to reduce carbon emissions.

Grano’s Customizable Solutions for Bioenergy Systems

Grano makes flexible plate evaporators for renewable projects, like fuels from algae or farm waste. They choose materials based on the liquid’s thickness or harshness, making their systems work well for different needs.

How Do Plate Evaporators Help Manage Industrial Wastewater?

Water Recovery from Industrial Effluents Using Plate Evaporators

Many industries face strict water waste rules. Plate evaporators help by pulling clean water from dirty liquids through evaporation. This supports goals like zero-liquid-discharge (ZLD).

Eco-friendly cleaning, water recovery, and reuse are becoming standard in industries.

Minimizing Environmental Impact Through Efficient Evaporation

By evaporating waste instead of using chemicals, you reduce waste volume. This lowers disposal costs and helps meet environmental rules more easily.

Grano’s Sustainable Technologies for Water Reuse

Grano’s plate evaporators use rust-proof materials for wastewater with salts, acids, or metals. They fit into ZLD plans for industries like mining, textiles, or electronics.

What Role Do Plate Evaporators Play in HVAC & District Heating?

Heat Reuse Through Condensate Recovery

In HVAC and district heating, plate evaporators recover water and heat from steam systems. This saves water and reuses heat that would be lost, making systems more efficient.

Enhancing System Coefficients of Performance (COP)

By improving heat recovery in cooling or heating systems, plate evaporators boost the system’s COP. This means lower energy bills all year.

Compact Footprint Ideal for Urban Infrastructure

City buildings need small, strong equipment. Plate evaporators are modular and easy to maintain, fitting well in tight spaces like mechanical rooms or rooftops.

Grano’s Integration Capabilities with Modern HVAC Designs

Grano’s solutions work with smart building systems. They support both new projects and updates to old systems in commercial buildings worldwide.

What Will Drive Future Market Growth Toward 2025?

Growing Demand for Modular, Scalable Evaporation Systems

Industries are moving to smaller, flexible production, like microbreweries or mobile medicine units. Plate evaporators are perfect because they can grow without big changes to setups.

Regulatory Pressures Driving the Need for Energy Efficiency

Governments are setting tougher rules on emissions and resource use. Your factory needs equipment that saves energy while keeping up production. Plate evaporators do this better than older systems like drum dryers.

How Grano Is Positioned to Meet Emerging Industry Needs

Grano follows strict quality rules with ISO 9001:2015 certification. They invest in research for eco-friendly designs, automation, and new materials. This prepares them for future needs in industries like medicine, chemicals, and HVAC.

FAQ

Q: Can I use a plate evaporator in corrosive chemical environments?

A: Yes! Models with titanium or duplex stainless steel are built for tough conditions with acids or solvents in chemical work.

Q: How often should I clean my plate evaporator?

A: It depends on the liquid and how long it runs. Cleaning usually happens every few weeks or every few months. Regular checks stop dirt buildup, which hurts efficiency.

Q: Is it possible to retrofit an existing system with a new plate evaporator?

A: Definitely! Grano’s modular designs fit into existing pipes with little disruption during setup.