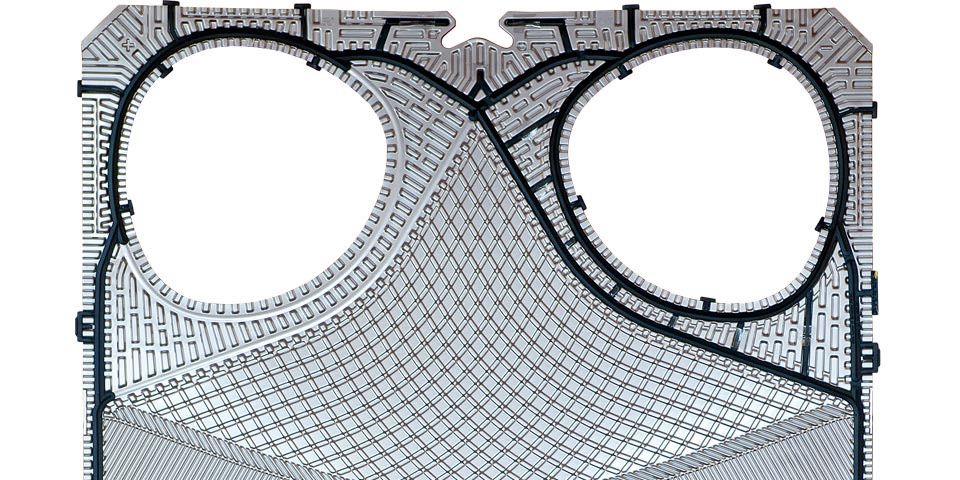

In the world of plate heat exchangers, precision isn’t just a requirement—it’s the cornerstone of performance. That’s why our adhesive pads are meticulously hand-applied, blending human expertise with industry-leading techniques to ensure a flawless seal every time.

our skilled technicians bring a discerning eye and a steady hand to each pad application. This hands-on approach allows us to tailor each seal to the unique contours of your heat exchanger plates, minimizing the risk of leaks and maximizing thermal efficiency. Whether you’re dealing with high-pressure systems or intricate geometries, our custom-fit adhesive pads provide the reliability you need to keep your operations running smoothly.

In addition to our precision craftsmanship and strict quality control, we offer a range of value-added services designed to meet your specific needs. Our team of experts can provide technical support, installation guidance, and customized solutions to help you optimize your heat exchange system. We understand that every application is unique, and we’re dedicated to working with you to find the best solution for your specific requirements.Contact us today to learn more about our products and services, and let us help you take your heat exchange performance to the next level.

Packaging Methods for Plate Heat Exchanger Plates and Gaskets

Packaging for Heat Exchanger Plates

Each plate is thoroughly inspected before packaging. Plates are then individually wrapped in soft, protective material (e.g., bubble wrap or foam film) to guard against scratches and impacts. Wrapped plates are stacked with rigid plastic dividers between each layer to prevent friction and maintain stability.

For larger plates: Plates are positioned into aluminum cases lined with high-density foam. The foam is shaped to fit the plates snugly, and they are secured with nylon straps to eliminate any movement. Cases are sealed after a final check for stability.