ہر منٹ آپ کی فیکٹری لائن ایک پرانے یا غیر موثر ہیٹر کے ساتھ چلتی ہے، آپ لفظی طور پر اپنے ممکنہ منافع کو جلا رہے ہیں. کھانا اور مشروبات بنانے کی مسابقتی دنیا میں، آپ کا پیسٹرائزر آپ کی پوری پیداوار کا دل ہے. اگر یہ ناکام ہو جاتا ہے یا توانائی ضائع ہوتی ہے تو آپ کا پورا کاروبار درد محسوس کرتا ہے۔ گرینو پیسٹرائزیشن یونٹس کو اس فضلہ کو روکنے اور آپ کے برانڈ کو خراب گرمی کے علاج کے خطرات سے بچانے کے لئے ڈیزائن کیا گیا ہے۔ جبکہ زیادہ تر لوگ کھانے کی حفاظت کے بارے میں سنتے وقت گروسری اسٹور کے شیلف کے بارے میں سوچتے ہیں، فیکٹری کے مینیجرز جانتے ہیں کہ اصل کام سٹینلیس سٹیل کی پائپوں کے اندر گہری گہرائی سے ہوتا ہے.

کامل گرمی کا حقیقی معنی سمجھنا

سادہ الفاظ میں، پیسٹرائزیشن اعداد و شمار کا ایک کھیل ہے جہاں آپ کو کھونے کے لئے برداشت نہیں کر سکتے ہیں. آپ کو ایک مخصوص درجہ حرارت کو مارنا ہوگا اور ایک مخصوص وقت کے لئے وہاں رہنا ہوگا۔ سائنسدانوں نے یہ “ وقت درجہ حرارت ” تعلقات یہ بنیادی طور پر میکروبوں کو مارنے کے لئے ایک اعلی اسٹیک ٹائمر ہے. اگر درجہ حرارت بھی تھوڑا سا کم ہے تو خطرناک بیکٹیریا جیسے لسٹریا یا سالمونیلا رس یا دودھ میں زندہ رہ سکتے ہیں۔ لیکن اگر مشین بہت گرم ہو جاتی ہے تو دودھ میں موجود پروٹین ٹوٹنا شروع ہوتا ہے یا رس اپنی قدرتی پھلوں کی بو کھو دیتا ہے اور اس کا ذائقہ زیادہ پکانا جاتا ہے۔

گرینو یونٹس ایک نظام کا استعمال کرتے ہیں جسے پریسجن تھرمل مینجمنٹ کہا جاتا ہے۔ اس کا مطلب یہ ہے کہ مشین گرمی کو کس طرح سنبھالتی ہے اور تبدیلیوں پر رد عمل کرتی ہے اس کے بارے میں بہت ہوشیار ہے۔ ہمارے خصوصی استعمال پلیٹ ہیٹ ایکسچینجرز ((PHE) ، گرینو سسٹم اس بات کو یقینی بناتا ہے کہ آپ کی مصنوعات کی ہر ایک قطرہ بالکل صحیح مقدار میں گرمی حاصل کرتی ہے. ہم don’ کسی بھی “ تھرمل لیگ ، ” جو صرف یہ کہنے کا ایک فینسی طریقہ ہے کہ مشین گرم یا ٹھنڈا ہونے میں بہت وقت لگتا ہے۔ گرمی تیز ہے، یہ مستحکم ہے، اور یہ ہر بار صحیح ہے.

کثیر مرحلے کے ڈیزائن اور توانائی کی بچت کا راز

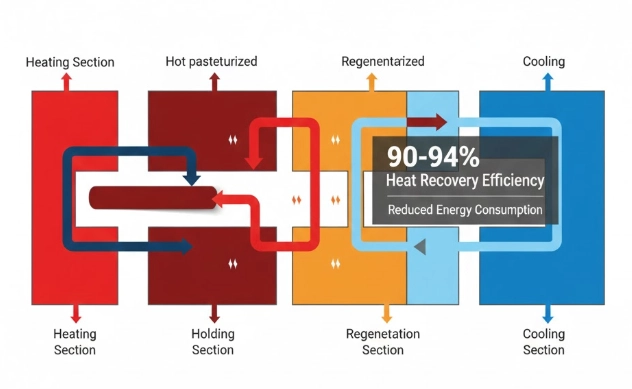

ایک گرینو پیسٹرائزیشن یونٹ صرف ایک سادہ ہیٹر نہیں ہے جیسا کہ آپ کے باورچی خانے میں ہے۔ یہ دراصل ایک بہت ہوشیار مشین ہے جو بہت سے مختلف حصوں سے بنائی گئی ہے جو ہم ایک کثیر مرحلے کی ساخت کہتے ہیں۔ اگر آپ ایک گرینو مشین کے اندر دیکھتے ہیں تو ، آپ کئی مختلف حصوں کو دیکھیں گے جو بہترین نتائج کو یقینی بنانے کے لئے مائع بہتا ہے:

سب سے پہلے، گرمی کا حصہ ہے. یہ وہاں ہے جہاں ہم بھاپ یا گرم پانی کا استعمال کرتے ہیں تاکہ مصنوعات کو جلدی درجہ حرارت تک پہنچایا جاسکے جس کی ہمیں میکروبوں کو مارنے کی ضرورت ہے۔ اگلا ہولڈنگ سیکشن آتا ہے ، جو ایک لمبی ٹیوب ہے جہاں مصنوعات سیکنڈ کی ایک مخصوص تعداد کے لئے گرم رہتی ہے تاکہ اس بات کو یقینی بنایا جاسکے کہ جراثیم اصل میں چلے گئے ہیں۔ اس کے بعد، ہمارے پاس کولنگ سیکشن ہے، جو درجہ حرارت کو واپس نیچے لاتا ہے تاکہ مصنوعات کو خراب یا رنگ تبدیل کرنے کے بغیر بوتلوں میں ڈال دیا جاسکے۔

لیکن سب سے دلچسپ حصہ - اور وہ حصہ جو آپ کو سب سے زیادہ پیسے بچاتا ہے - ریجنریشن سیکشن ہے ، جسے گرمی کی بحالی کے نظام کے طور پر بھی جانا جاتا ہے۔

کیوں 90-94 فیصد کارکردگی ایک بہت بڑا سودہ ہے

سوچیں کہ ہر روز ہزاروں لیٹر دودھ گرم کرنے کے لئے کتنی توانائی کی ضرورت ہوتی ہے۔ اس کی قیمت بہت بڑی رقم ہے. ایک پرانے فیشن کی مشین میں، یہ تمام گرمی صرف جب آپ دودھ کو ٹھنڈا کرتے ہیں تو ضائع ہو جاتی ہے. لیکن گرینو مختلف ہے کیونکہ ہمارا ہیٹ ریکوری سسٹم ریلے ریس کی طرح کام کرتا ہے۔

جب گرم، تیار مصنوعات کولنگ کے علاقے کی طرف منتقل ہوتی ہے، تو یہ ٹھنڈی، خام مصنوعات کے ساتھ گزرتی ہے جو صرف مشین میں داخل ہو رہی ہے. چونکہ وہ ہماری ہائی ٹیک پلیٹوں کے اندر ایک ساتھ بہت قریب ہیں، گرم مائع سرد مائع کو اپنی گرمی دیتا ہے. اس کا مطلب یہ ہے کہ سرد مائع مفت سے پہلے گرم ہوتا ہے، اور گرم مائع مفت سے پہلے ٹھنڈا ہوتا ہے.

توانائی کی بچت: گرینو یونٹس گرمی کا 90٪ سے 94٪ ری سائیکل کرسکتے ہیں ، جو صنعت کی معروف کارکردگی ہے۔

پیسے کی بچت: کیونکہ مشین خود ہی حرارتی کام کا بہت زیادہ کام کر رہی ہے ، آپ کی فیکٹری نہیں کرتی ہے ’ t بوائلر سے تقریبا زیادہ بھاپ استعمال کرنے کی ضرورت ہے.

پائیداری: یہ آپ کے ماہانہ بلوں کو کم کرتا ہے اور ماحول کے لئے بہت بہتر ہے ، آپ کی فیکٹری کو پورا کرنے میں مدد ملتی ہے “؛ سبز” اہداف

ایک مشین کی تعمیر جو سپر صاف رہتا ہے

کھانے کی فیکٹری میں “ زیادہ تر صاف” اصل میں بہت خطرناک ہے. اگر کسی مشین کے کونے میں بھی تھوڑا سا پرانا دودھ یا رس پھنس جاتا ہے تو بیکٹیریا بڑھنا شروع ہو جائے گا اور ہر چیز کو آلودہ کرے گا۔ اسی وجہ سے گرینو دنیا کے سخت ترین قواعد کو پورا کرنے کے لئے ہر یونٹ کی تعمیر کرتا ہے ، جیسے ایف ڈی اے (امریکی فوڈ اینڈ ڈرگ ایڈمنسٹریشن) اور 3 اے سینیٹری اسٹینڈرڈز۔ یہ حفاظت کے لئے سونے کے معیار ہیں. آپ ان حفاظت کی ضروریات کی تصدیق ایف ڈی اے کی سرکاری فوڈ سیفٹی ویب سائٹ پر کرسکتے ہیں تاکہ یہ دیکھ سکیں کہ ہمارا حفاظت صحت ڈیزائن جدید پیداوار کا غیر قابل مذاکرات حصہ کیوں ہے۔

صرف بہترین مواد کا استعمال کرتے ہوئے: SS316L سٹینلیس سٹیل

تمام اسٹیل ایک ہی نہیں ہیں. بہت سی سستی مشینیں 304 سٹینلیس سٹیل کا استعمال کرتی ہیں ، جو اگر آپ نارنجی یا لیمو کے رس جیسے تیزادی رس پر عمل کر رہے ہیں تو زنگ لگ سکتی ہیں۔ گرینو معیار پر کونے کاٹنے سے انکار کرتا ہے. ہم اس مشین کے ہر حصے کے لئے SS316L سٹینلیس سٹیل کا استعمال کرتے ہیں جو آپ کے کھانے کو چھوتا ہے. اس قسم کی سٹیل بہت زیادہ سخت ہے اور پھلوں میں تیزاب اور صفائی کے کیمیکلز کو نقصان پہنچانے یا گڑھنے کے بغیر فیکٹریوں میں استعمال کیا جا سکتا ہے.

ہم ایک عمل بھی استعمال کرتے ہیں جسے الیکٹروپولنگ کہا جاتا ہے۔ یہ دھات کی سطح کو اتنا ہموار بناتا ہے کہ یہ ایک آئینے کی طرح نظر آتا ہے. اگر آپ نے اسے ایک مائکروسکوپ کے تحت دیکھا تو آپ’ کسی بھی کھڑچ یا گریز دیکھیں. یہ اہم ہے کیونکہ بیکٹیریا چھوٹے کھڑچیوں میں چھپانے سے محبت کرتا ہے جہاں برش کر سکتے ہیں ’ T پہنچنے جب دھات اتنی ہموار ہوتی ہے تو بیکٹیریا کو چھپانے اور بڑھنے کے لئے کہیں نہیں ہوتا۔

کوئی مردہ زون اور آسان صفائی

کچھ مشینوں کے ساتھ ایک اور بڑا مسئلہ “ مردہ زون” یہ چھوٹے کونے یا خلا ہیں جہاں مائع چلنے سے روکتا ہے اور صرف وہاں بیٹھتا ہے۔ یہ میکروبوں کو بڑھانے کے لئے ایک بہترین جگہ ہے. گرینو مشینیں “ ہونے کے لئے ڈیزائن کی گئی ہیں؛ مردہ زون مفت” مائع ہمیشہ تیز رفتار، گھومنے والے طریقے سے چلتا ہے تاکہ کچھ بھی حل نہیں ہو سکتا.

یہ ڈیزائن سی آئی پی (کلین ان پلیس) کو بہت آسان اور بہت تیز بناتا ہے۔ سی آئی پی کا مطلب یہ ہے کہ آپ اس کے ذریعے خصوصی صابن اور پانی چلائے ہوئے پوری مشین کو صاف کرسکتے ہیں بغیر پوری چیز کو الگ کرنے کے۔ چونکہ گرینو یونٹ میں ہموار راستے اور خصوصی فوڈ گریڈ گیسکٹ ہیں ، صفائی کا مائع ہر ایک جگہ تک پہنچ سکتا ہے ، مشین کو مکمل طور پر تازہ اور مصنوعات کے اگلے بیچ کے لئے تیار چھوڑ سکتا ہے۔

ہولڈنگ ٹیوب کے اندر سائنس

پورے عمل کا سب سے اہم حصہ یہ ہے کہ مصنوعات گرم ہونے میں خرچ ہوتی ہے۔ یہ صحت سے متعلق ہولڈنگ ٹیوب کی طرف سے ہینڈل کیا جاتا ہے. ہم don’ ٹی صرف اندازہ لگائیں کہ ٹیوب کتنی دیر تک ہونا چاہئے؛ ہم اسے درست کرنے کے لئے ریاضی اور طبیعیات کا بہت استعمال کرتے ہیں.

اس بات کو یقینی بنانے کے لئے کہ مصنوعات بالکل 15 سیکنڈ تک گرم رہتی ہے (جو دودھ کے لئے ایک عام اصول ہے) ، ہمیں مائع کی رفتار اور پائپ کی لمبائی کا حساب لگانا ہوگا۔ ریاضی تھوڑا سا اس طرح لگتا ہے:

t = (V / Q) × η

اس فارمولے میں، V پائپ کا حجم ہے، Q یہ ہے کہ پمپ مائع کو کتنی تیزی سے دھکا رہا ہے، اور η ایک خاص نمبر ہے جو اس بات کا حساب دیتا ہے کہ مائع پائپ کی دیواروں کے خلاف کیسے گھڑتا ہے۔ اس ریاضی کو بالکل صحیح طور پر حاصل کرکے، گرینو اس بات کو یقینی بناتا ہے کہ پائپ کے وسط میں سب سے تیزی سے چلنے والی رس کی قطرہ بھی قانون کے مطابق مطلوبہ پورے وقت کے لئے قتل کے درجہ حرارت پر رکھی جاتی ہے. اس کا مطلب یہ ہے کہ آپ کو کبھی بھی ایک “ کے بارے میں فکر کرنے کی ضرورت نہیں ہے؛ خراب بیچ” یہ ’ کافی وقت تک علاج کیا جاتا ہے.

بہت سے مختلف ملازمتوں کے لئے ایک مشین

اگرچہ بہت سے لوگ دودھ کے بارے میں سوچتے ہیں جب وہ لفظ پیسٹرائزیشن سنتے ہیں، گرینو یونٹس دراصل ہر قسم کی مختلف مصنوعات کے لئے بہت اچھے ہیں. ہمارے انجینئرز آپ جو بھی بنا رہے ہیں اس کے لئے پلیٹوں کے ڈیزائن کو تبدیل کر سکتے ہیں.

اگر آپ ایک HTST (ہائی درجہ حرارت مختصر وقت) دودھ پیسٹرائزر کی تلاش کر رہے ہیں تو ، ہمارے سیٹ اپ میں باقاعدہ دودھ ، بھاری کریم ، دہی کی بنیاد ، اور یہاں تک کہ آئس کریم بنانے کے لئے استعمال ہونے والا موٹی مرکب بھی شامل ہے۔ یہ نظام دودھ کی مصنوعات کو تازہ رکھنے پر توجہ مرکوز کرتے ہیں جبکہ یہ یقینی بناتے ہیں کہ یہ شیلف کے لئے مکمل طور پر محفوظ ہے۔

اگر آپ صنعتی رس پیسٹرائزیشن کے سامان کی تلاش کر رہے ہیں جو موٹی پلپ یا اعلی تیزابیت کو سنبھال سکتے ہیں تو ، گرینو کا وائڈ گیپ ڈیزائن جواب ہے۔ چاہے یہ ایک صاف سیب کا رس ہو یا ایک موٹی انگو کا رس جس میں بہت سے پلپ ہوتے ہیں، ہماری مشینیں بغیر بند ہونے کے بہاؤ کو سنبھال سکتی ہیں۔

ہم بھی مدد کرتے ہیں:

چائے اور پانی: بوتلوں میں آئس چائے اور خصوصی “ فعال” پانی کو مہینوں تک شیلف پر محفوظ رہنے کے لئے گرمی کے علاج کی ضرورت ہے۔

بیئر بنانے والے ہماری مشینیں استعمال کرتے ہیں “ فلیش pasteurization” یہ خمیر اور بیکٹیریا کو مارتا ہے تاکہ بیئر بیئر کے ذائقے، بو، یا نظر کے طریقے کو تبدیل کرنے کے بغیر بوتل میں اچھا رہتا ہے.

کیوں گرانو کا انتخاب آپ کے کاروبار کے لئے ایک سمارٹ اقدام ہے

ایک پیسٹرائزیشن مشین خریدنا کسی بھی کمپنی کے لئے ایک بڑا فیصلہ ہے، کیونکہ توانائی کی موثر گرمی کے تبادلے کی لاگت آپ کے مستقبل میں سرمایہ کاری ہے. جب آپ ایک Grano Pasteurization یونٹ کا انتخاب کرتے ہیں، تو آپ’ صرف سٹیل پائپوں کا ایک گروپ خریدنے کے لئے. آپ ذہنی امن خریدتے ہیں. آپ ایک مشین خرید رہے ہیں جو آپ کے گاہکوں اور آپ کی ساکھ کی حفاظت کے لئے بنائی گئی ہے.

ہماری ہائی ٹیک گرمی کی بحالی، اعلی معیار کے SS316L مواد، اور بہت درست ہولڈنگ ٹیوبوں کا استعمال کرتے ہوئے، ہم فیکٹری کے مالکان تین اہم چیزیں کرنے میں مدد کرتے ہیں:

کم پیسے خرچ کریں: آپ بہت کم بھاپ اور پانی استعمال کرتے ہیں، جس سے آپ کو ہر سال آپریٹنگ اخراجات میں ہزاروں ڈالر بچاتے ہیں۔

بہتر مصنوعات بنائیں: آپ کا رس تازہ مزہ حاصل کرے گا اور آپ کے دودھ میں زیادہ وٹامن ہوں گے کیونکہ ہم ’ T زیادہ گرم مصنوعات یا استعمال “ سستی” ٹھنڈا.

ہر معائنہ پاس کریں: جب ایک فوڈ سیفٹی انسپکٹر آپ کی فیکٹری میں آتا ہے تو ، آپ انہیں اپنے گرانو سسٹم دکھا سکتے ہیں اور جانتے ہیں کہ آپ مکمل اعتماد کے ساتھ اعلی ترین ایف ڈی اے اور 3 اے قواعد کو پورا کر رہے ہیں۔

کھانے کی پیداوار کی مصروف دنیا میں، توانائی پر کم خرچ کرتے ہوئے ایک محفوظ، اعلی معیار کی مصنوعات بنانے کے قابل ہونا آپ کے حریفوں کو شکست دینے کا بہترین طریقہ ہے. گرینو اس بات کو یقینی بنانے کے لئے یہاں ہے کہ آپ کی فیکٹری پہلے سے بہتر چلتی ہے۔

کیا آپ دیکھنا چاہتے ہیں کہ کس طرح ایک گرینو مشین آپ کی فیکٹری میں مدد کرسکتی ہے؟ رابطہ کریں آج گرینو انجینئرنگ ٹیم اور ہمیں آپ کے کاروبار کے لئے بہترین نظام ڈیزائن کرنے میں مدد کرنے دو.

سوالات

سوال: کیا مجھے اسے دھونے کے لئے ہر روز گرانو پیسٹرائزیشن یونٹ کو الگ کرنا پڑتا ہے؟

جواب: نہیں، آپ کو یقینی طور پر don’ ایسا کرنے کی ضرورت ہے. ہماری مشینیں کسی ایسی چیز کے لئے بنائی گئی ہیں جسے سی آئی پی (کلین ان پلیس) کہا جاتا ہے۔ مشین کے اندر بہت ہموار الیکٹروپولسڈ SS316L سٹیل سے بنا ہے، اور صفائی کا مائع تمام باقی کھانے کو بہت آسانی سے دھوڑ سکتا ہے. آپ کو عام طور پر صرف ایک سال میں ایک بار مشین کھولنے کی ضرورت ہوتی ہے تاکہ یہ یقینی بنایا جاسکے کہ ربڑ کی مہر اب بھی اچھی شکل میں ہیں۔

سوال: کیا گرینو مشین ان میں پھل کے ٹکڑے کے ساتھ موٹی مائع کو سنبھال سکتی ہے؟

جواب: جی ہاں! جبکہ ایک معیاری پلیٹ موٹی پلپ کی طرف سے بند ہو سکتا ہے، Grano خصوصی “ بناتا ہے؛ وسیع خلا” پلیٹ ان پلیٹوں میں ان کے درمیان زیادہ جگہ ہے لہذا ٹماٹر کے ساس یا اینگو پلپ جیسے موٹی مائع پھنس کے بغیر بہ سکتے ہیں۔

سوال: میں توانائی کی بچت سے اپنے پیسے کتنی جلدی واپس لے جاؤں گا؟

جواب: چونکہ ہماری گرمی کی وصولی بہت اچھی ہے - 90٪ اور 94٪ کے درمیان - زیادہ تر فیکٹری مالکان فوری طور پر اپنی بجلی اور گیس کے بلوں پر بہت زیادہ رقم بچاتے ہیں۔ اس بات پر منحصر ہے کہ آپ مشین کو کتنا استعمال کرتے ہیں، آپ توانائی پر بچاتے ہوئے پیسے اکثر صرف ایک یا دو سال میں یونٹ کی پوری لاگت کی ادائیگی کرسکتے ہیں. یہ آپ کی فیکٹری کو زیادہ منافع بخش بنانے کے بہترین طریقوں میں سے ایک ہے.